Ultrasonic remediating method for heavy metal polluted soil/slurry

A heavy metal-contaminated soil and repair method technology, applied in the field of environmental engineering, can solve the problems of high treatment costs, achieve low treatment costs, avoid soil property changes, and be easy to achieve

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

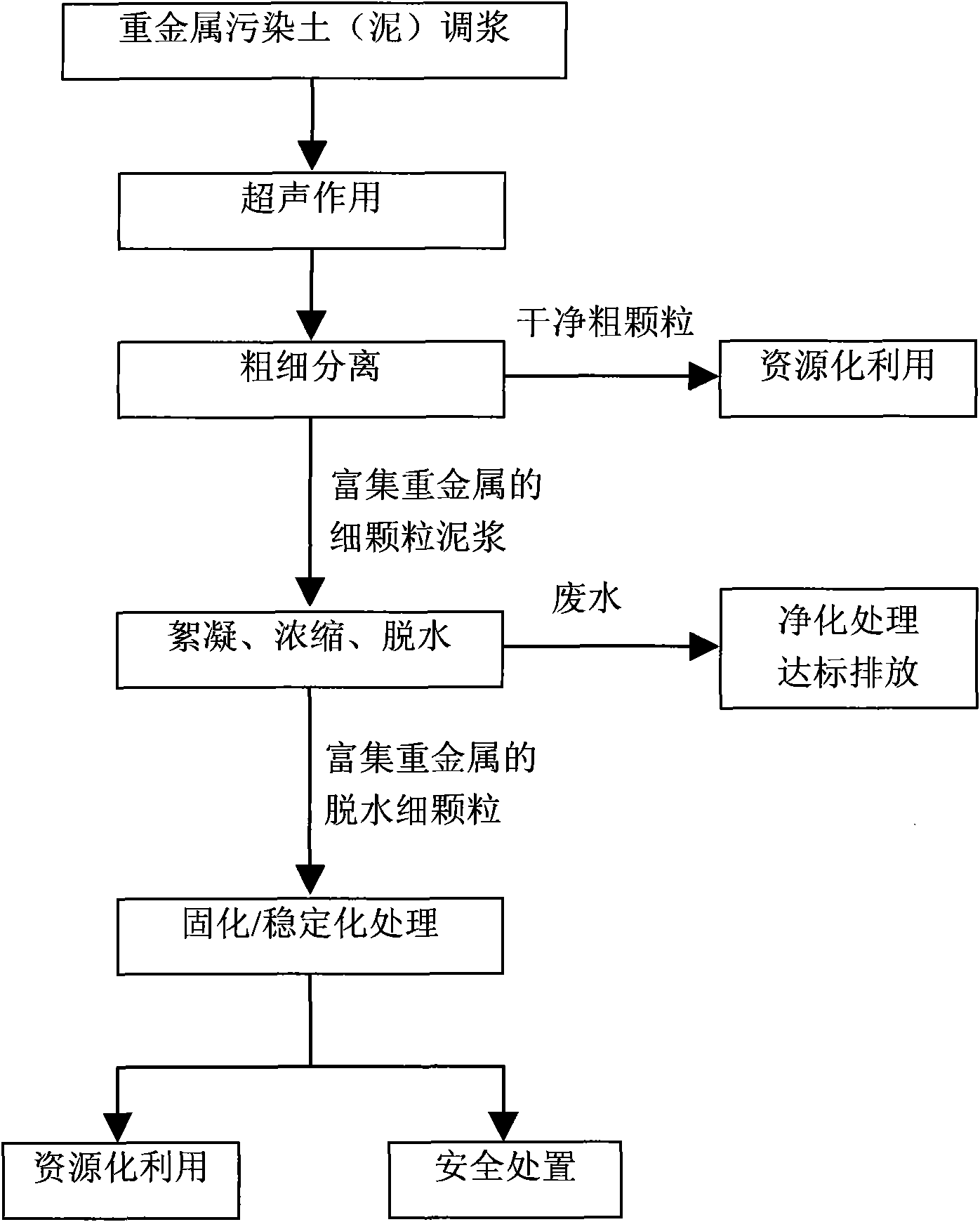

Method used

Image

Examples

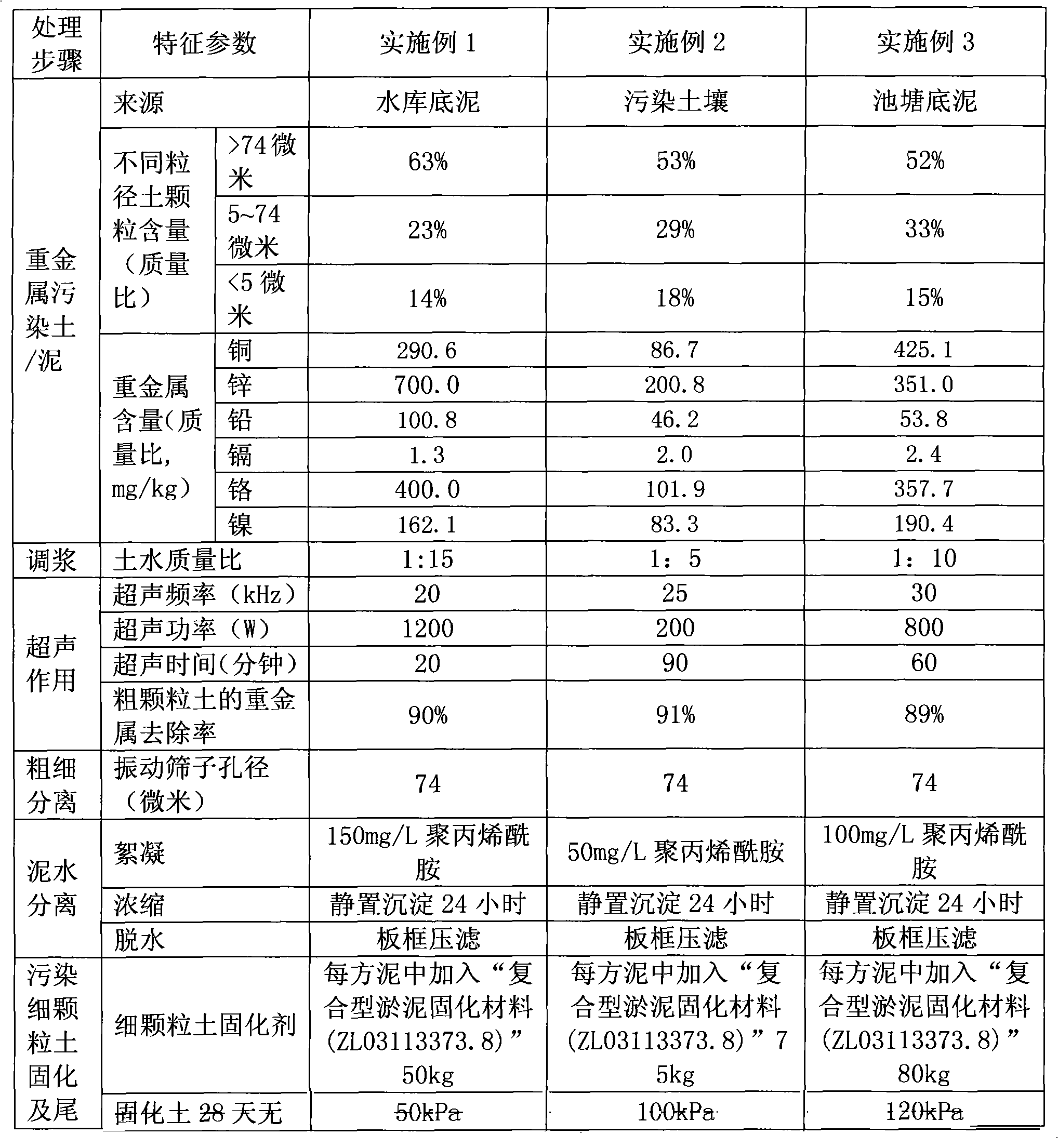

Embodiment 1

[0024] A heavy metal polluted dredging sediment of a reservoir, the content of particles of different particle sizes in the sediment is: the content of particles larger than 74 microns is 63%, the content of particles of 5-74 microns is 23%, and the content of particles smaller than 5 microns is 14% . The contents of copper, zinc, lead, cadmium, chromium, and nickel in the sediment are 290.6mg / kg, 700.0mg / kg, 100.8mg / kg, 1.3mg / kg, 400.0mg / kg, and 162.1mg / kg respectively. Frequency 20kHz, power 1200W, soil water mass ratio 1:15 under the conditions, after ultrasonic action for 20 minutes, use a vibrating sieve with an aperture of 74 microns to get copper, zinc, lead, cadmium, chromium, The removal rate of nickel reaches 90%, and the coarse particles after treatment meet the first-class soil environmental quality standard (GB15618-1995). Add 150mg / L polyacrylamide to the mud under the sieve, let it settle for 24 hours, remove the bottom mud and dehydrate it with a plate and fra...

Embodiment 2

[0026] A kind of heavy metal polluted soil, the content of particles with different particle sizes in the bottom mud is: the content of particles larger than 74 microns is 53%, the content of particles between 5 and 74 microns is 29%, and the content of particles smaller than 5 microns is 18%. The contents of copper, zinc, lead, cadmium, chromium, and nickel in the sediment are 86.7mg / kg, 200.8mg / kg, 46.2mg / kg, 2.0mg / kg, 101.9mg / kg, and 83.3mg / kg respectively. Frequency 25kHz, power 200W, soil water mass ratio under the condition of 1:5, after 90 minutes of ultrasonic action, sieving with a vibrating sieve with an aperture of 74 microns to obtain copper, zinc, lead, cadmium, chromium, The removal rate of nickel reaches 91%, and the coarse particles after treatment meet the first-class soil environmental quality standard (GB15618-1995). Add 50mg / L polyacrylamide to the mud under the sieve, let it settle for 24 hours, remove the bottom mud and dehydrate it with a plate and frame...

Embodiment 3

[0028] A heavy metal polluted pond bottom sludge, the content of particles of different particle sizes in the bottom sludge is: the content of particles larger than 74 microns is 52%, the content of particles between 5 and 74 microns is 33%, and the content of particles smaller than 5 microns is 15%. . The contents of copper, zinc, lead, cadmium, chromium and nickel in the bottom mud are 525.1mg / kg, 351.0mg / kg, 53.8mg / kg, 4.4mg / kg, 357.7mg / kg, 190.4mg / kg respectively. Frequency 30kHz, power 800W, soil-water mass ratio 1:10, through ultrasonic action for 60 minutes, sieve with a vibrating sieve with an aperture of 74 microns to obtain copper, zinc, lead, cadmium, chromium, The removal rate of nickel reaches 92%, and the coarse particles after treatment meet the first-class soil environmental quality standard (GB15618-1995). Add 100mg / L polyacrylamide to the mud under the sieve, let it settle for 24 hours, remove the bottom mud and dehydrate it with a plate and frame filter pre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com