Process for online cut-to-length cutting production of continuous casting slabs for heavy plate mill

A technology of cut-to-length cutting and production technology, which is applied in the field of on-line cut-to-length cutting production technology of continuous casting slabs for thick plate rolling mills, and can solve the problem of lack of flexibility between the long billet cut-to-length cutting line and the main rolling line, and the artificial cold-loading of slabs. Cutting, unsatisfactory and other problems, to avoid low cutting length accuracy, flexible production, and reduce transportation costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

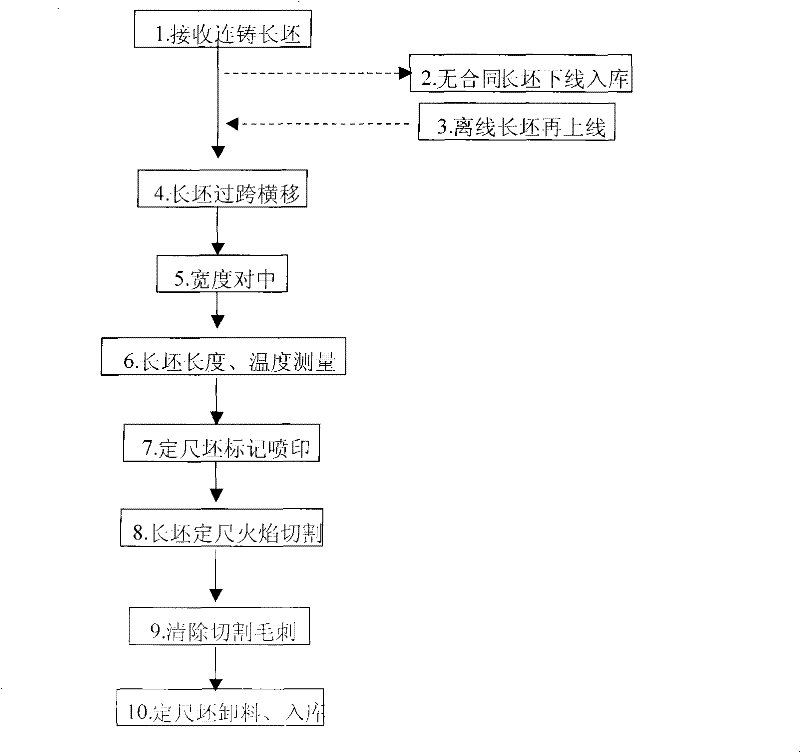

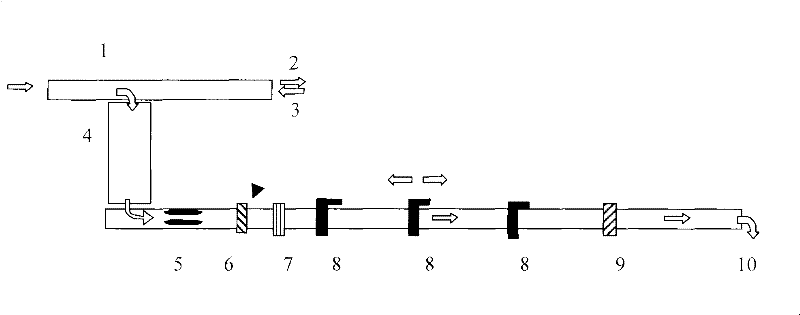

[0046] see figure 1 , figure 2 , the long slab produced by the slab continuous casting machine in the steelmaking plant is transported to the receiving roller table in the slab receiving span of the raw material warehouse of the thick plate factory through the roller table, where the long slab 1 is received. After completing the identity verification of long slabs, the long slabs without contracts are stored offline 2, and the offline slabs will be put online after the contract is matched 3. The long slab with the contract is directly sent to the slab receiving roller table of the secondary cutting line in the cutting span through the slab transfer machine cross-span 4. The long billet is transported to the centering roller table for width centering5. After centering, the long billet is transported to the length measuring and printing roller table to measure the length and temperature of the long billet6, and then carry out marking and printing on the billet to length acco...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com