High-purity creatine phosphate sodium compound

A technology of sodium phosphate and creatine phosphate, applied in the field of medicine, can solve the problems of long synthesis route, difficulty in purification, and large amount, and achieve the effects of improving purity and content, optimizing product quality, and ensuring safety

Inactive Publication Date: 2010-08-25

HAINAN MEIDA PHARMA

View PDF6 Cites 10 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The synthetic method reported in US3632603 and CN101033237A all takes creatinine as raw material to synthesize creatine phosphate sodium, but needs a large amount of phosphorus oxychloride reagent

Phosphorus oxychloride pollutes the environment and requires high equipment requirements, which is not conducive to large-scale production

US3036087 uses dibenzyl phosphite and methyl isothiourea as raw materials to synthesize creatine phosphate through a multi-step reaction, but the synthesis route of this method is too long, and toxic reagents such as mercuric oxide are used in the reaction, so safety protection in actual production High standard

In addition, in "Journal of Harbin University of Science and Technology" 2004, volume 9, No. 4, the synthesis of phosphocreatine with creatine as raw material was published, but the yield of this method is low, and barium salt is used in the synthesis, which brings certain problems to the purification of the product. difficulty

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention relates to a high-purity creatine phosphate sodium compound; by the acid-base reaction, the activated carbon adsorption and the preparation of chromatographic separation and purification, the purity and content of the creatine phosphate sodium is greatly increased, the product quality of the preparation is optimized and the safety of the clinical medication is guaranteed; and the method has simple technique, low cost and high yield and is suitable for industrialization production.

Description

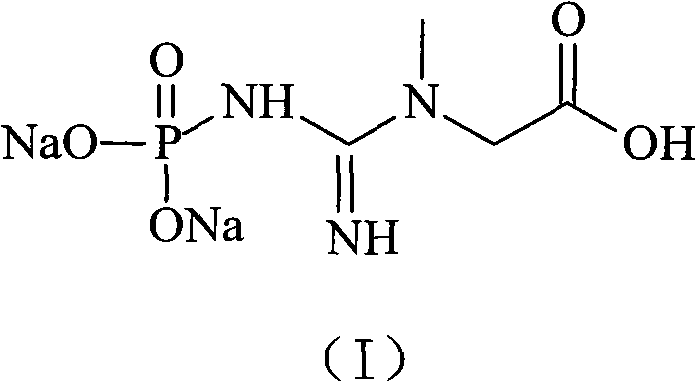

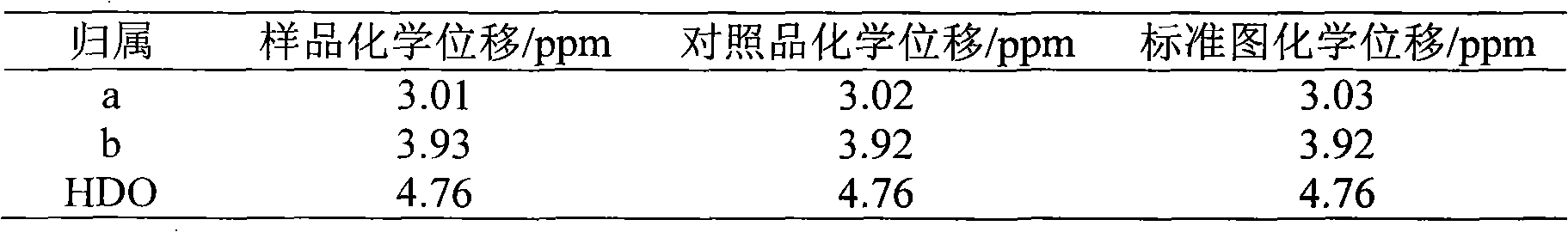

technical field The invention relates to a method for purifying creatine phosphate sodium compound. High-purity creatine phosphate sodium products can be obtained through the method of the invention, which belongs to the technical field of medicine. Background technique Sodium creatine phosphate, molecular formula: C 4 h 8 N 3 Na 2 o 5 P, molecular weight: 255.08, structural formula as follows: Creatine sodium phosphate plays an important role in the energy metabolism of muscle contraction. It is the chemical energy reserve of cardiac and skeletal muscles and is used for the resynthesis of ATP. The hydrolysis of ATP provides energy for the process of actomyosin contraction. It is suitable for treating myocardial ischemia, protecting the myocardium during cardiac surgery and other diseases with abnormal myocardial energy metabolism. At present, the production methods of creatine phosphate sodium include synthetic method, biological extraction method and enzyme catalys...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C07F9/22

Inventor 邱民

Owner HAINAN MEIDA PHARMA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com