Method for degrading cassava starch by pullulanase synergistic dual enzymatic method

A technology of pullulanase and tapioca starch, which is applied in the direction of fermentation, etc., can solve the problems of the degree of hydrolysis and glucose yield, and achieve the effects of improving the degree of hydrolysis and glucose yield, accelerating the saccharification process, and improving the saccharification efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] Example 1: Adjust the tapioca starch and water into a starch paste at a ratio of 1:3, first add pullulanase, heat it in a water bath to a temperature of 60°C under stirring, and keep it for 30min; then raise the temperature to 70°C, add α- Amylase, keep for 30min; finally lower the temperature to 60°C, add glucoamylase, keep for 30min.

Embodiment 2

[0018] Example 2: Adjust the tapioca starch and water into a starch paste in a ratio of 1:3, heat it in a water bath to a temperature of 70°C under stirring, add amylase and pullulanase at the same time, and keep it for 30min; then lower the temperature to 60°C, Add glucoamylase and keep for 30min.

Embodiment 3

[0019] Example 3: Adjust the tapioca starch and water into a starch paste in a ratio of 1:3, heat it in a water bath to a temperature of 70°C under stirring, first add amylase, and keep it for 30 minutes; then lower the temperature to 60°C, add glucoamylase and common Lulanase, keep for 30min.

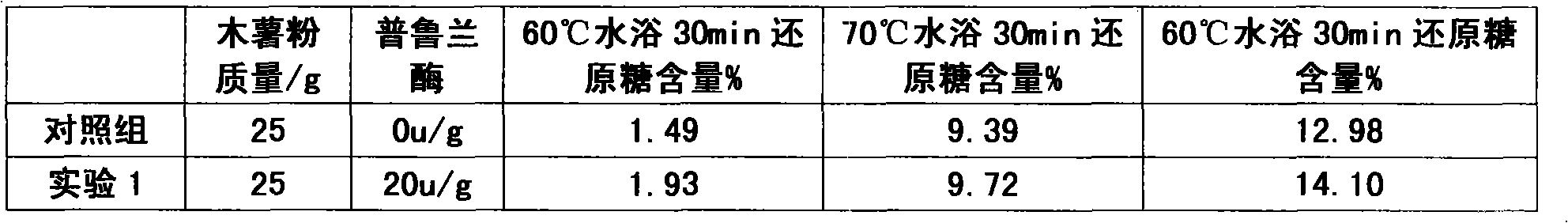

[0020] Table 1: Comparison of the order of addition of pullulanase, amylase, and glucoamylase to hydrolyze tapioca starch

[0021]

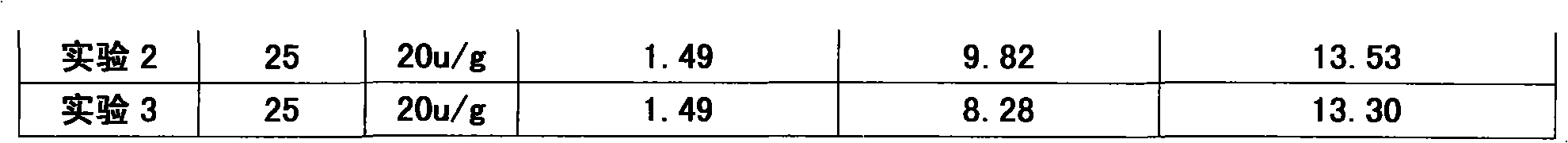

[0022] Table 2: The effect of the addition of pullulanase on the reducing sugar content of the system

[0023]

[0024]

[0025] It can be seen from the table that the content of reducing sugar in Experiment 1, where pullulanase was added first, was higher than that of other methods, and the content of reducing sugar in the system increased significantly.

[0026] (2) Dose-effect effect of pullulanase on cassava starch hydrolysis

[0027] According to the above experimental results, it is further adopted to add pullulanase to pretreat th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com