Method for testing thermo-oxidative ageing degree of polyethylene material

A detection method, thermal oxygen aging technology, applied in the direction of nuclear magnetic resonance analysis, etc., can solve the problems of complex sample preparation process, large random factors of test results, large sample volume, etc., to achieve reliable information, convenient and fast detection process, The effect of evaluation accuracy on performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

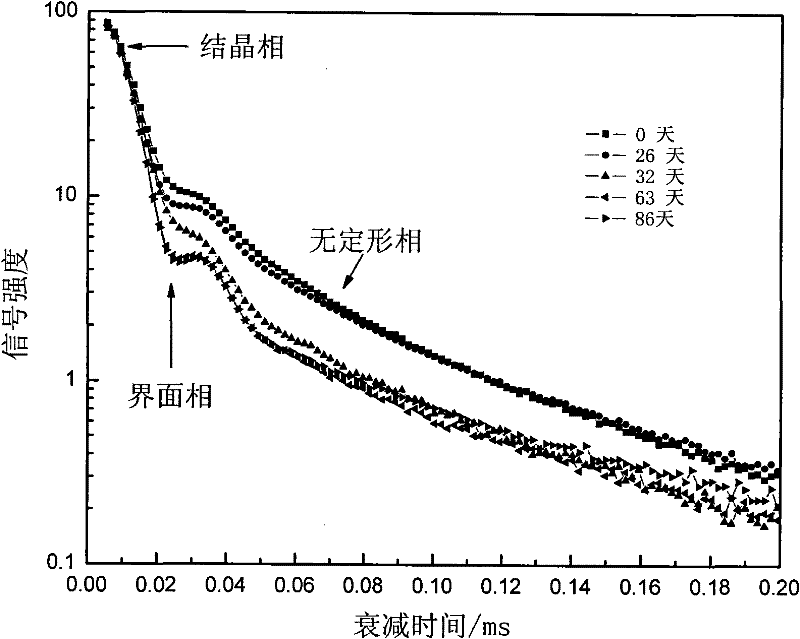

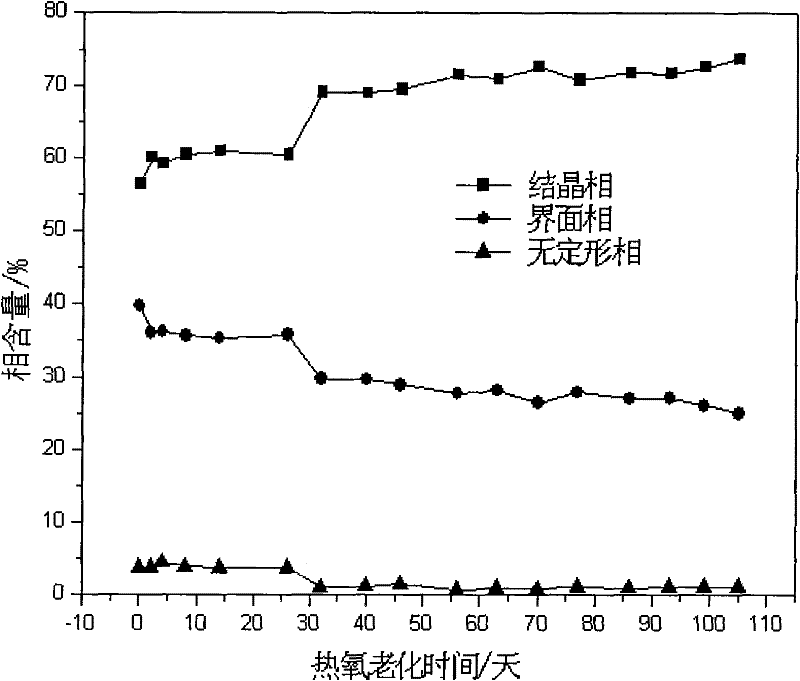

[0032] Select 1g of high-density polyethylene (density 0.949g / cm3) pipe material, put it into a thermo-oxidative aging test box and perform thermo-oxidative aging at 100°C. Take out and test its free induction decay curve (FID curve) regularly, and select several typical results such as figure 2 shown, along with the longitudinal relaxation decay curve. The abscissa of the FID curve is polyethylene 1 H is the decay time variable, and the ordinate is the signal strength corresponding to different times during the decay process. The rapid decay at the initial stage corresponds to the decay process of the polyethylene crystalline phase, and the slow decay after 0.04ms corresponds to the decay process of the polyethylene amorphous phase, and the transition decay process between the crystalline phase and the amorphous phase corresponds to the decay of the polyethylene interface phase process. With the change of aging time, the attenuation of each phase changes, and the interfac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com