Semiconductor laser

A technology of semiconductors and optical components, which is applied in the direction of semiconductor lasers, electrical components, laser components, etc., can solve problems such as single-mode degradation, and achieve high-speed response and single-mode performance, good initial characteristics and long-term reliability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

[0039] [structure]

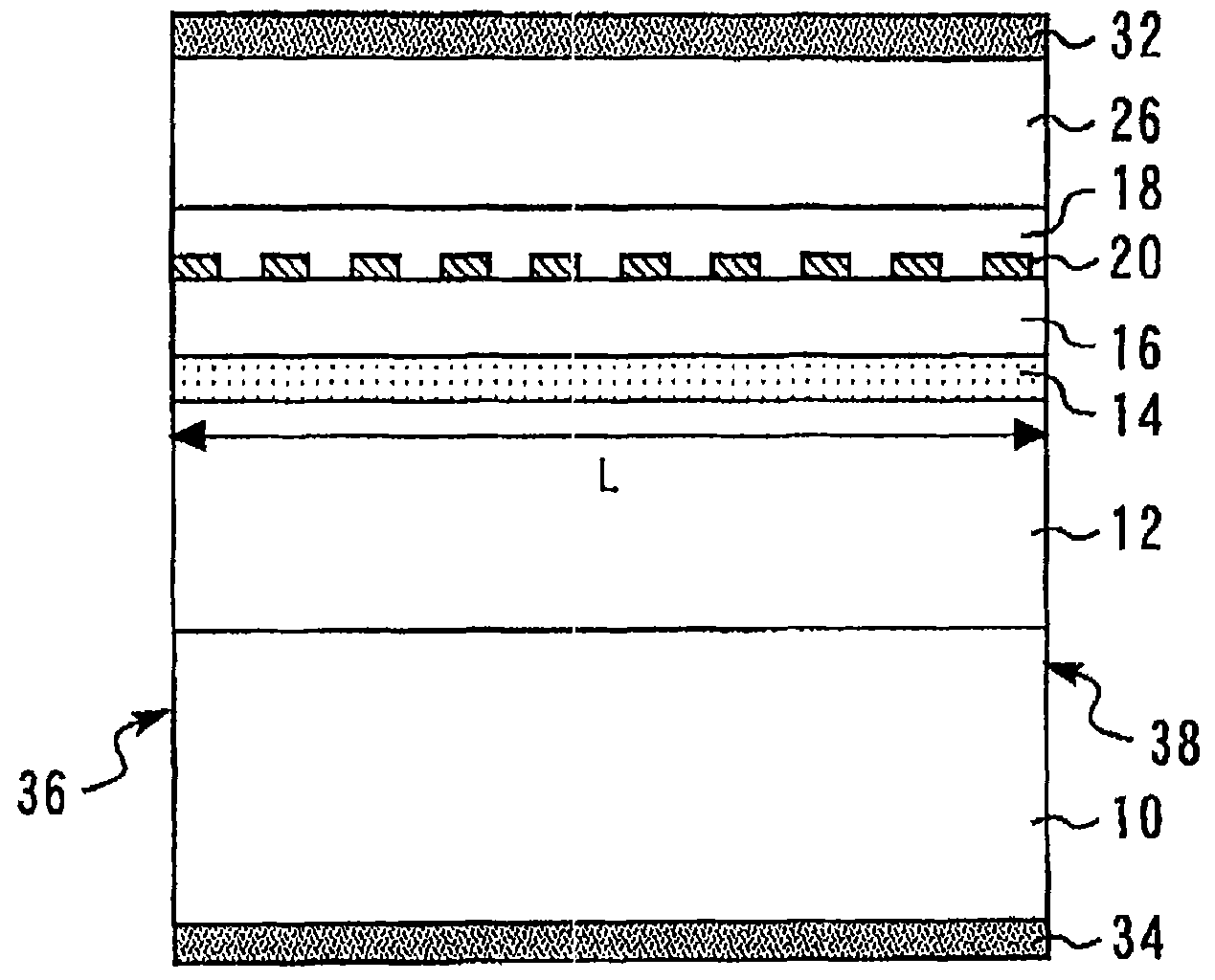

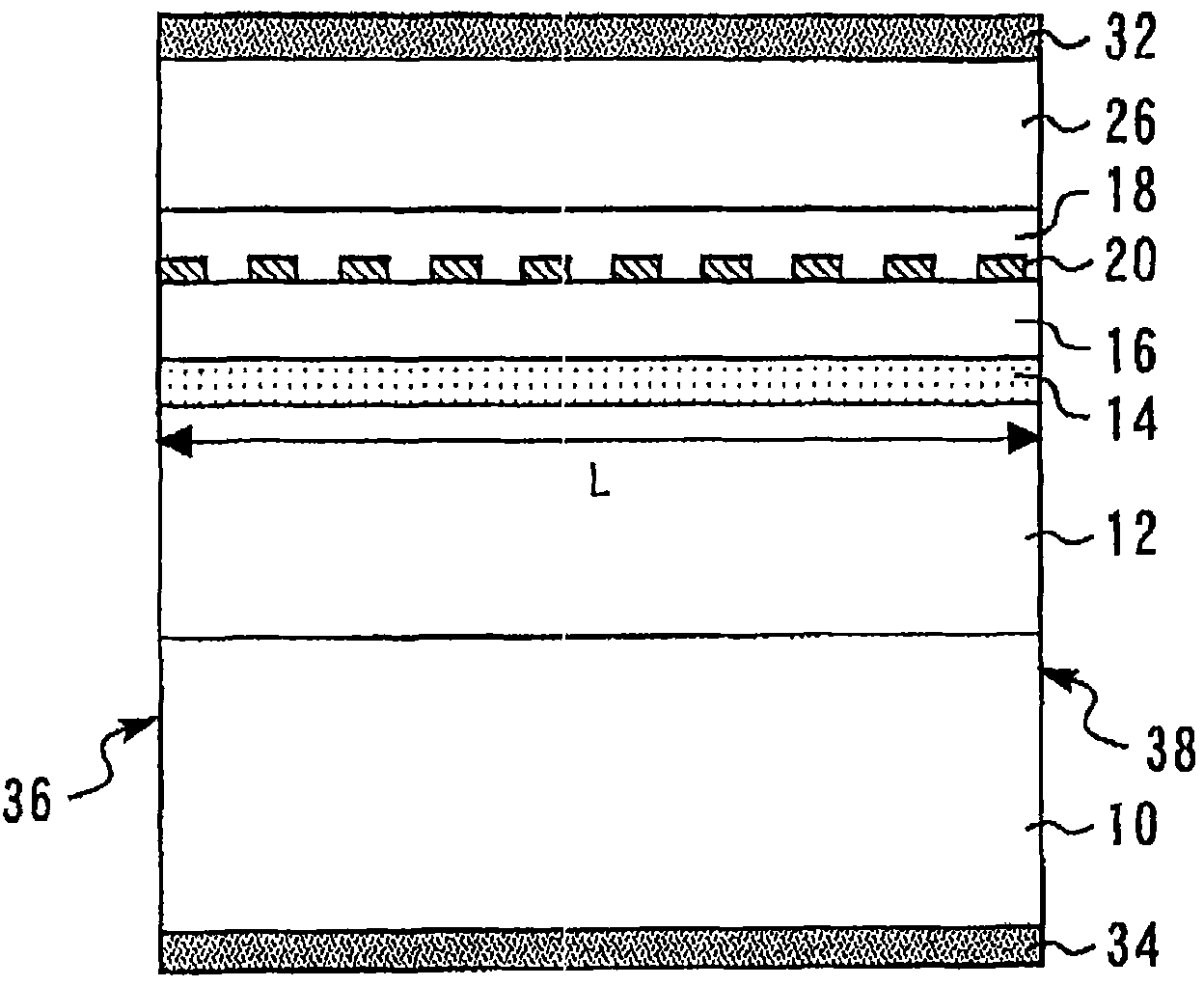

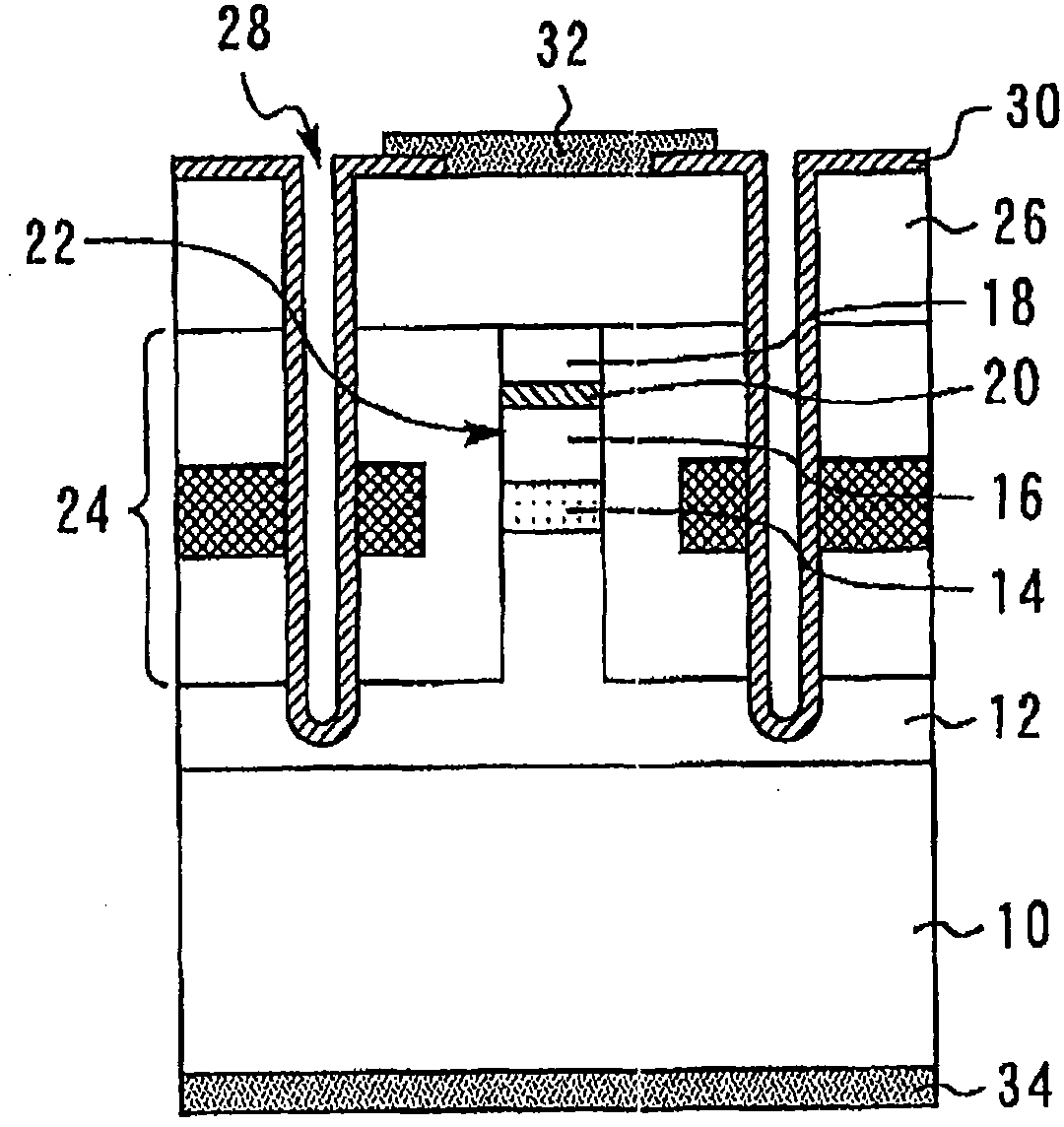

[0040] 1 and 2 are cross-sectional views showing a semiconductor optical element according to Embodiment 1. As shown in FIG. Fig. 1 is a sectional view in the direction of the optical waveguide, and Fig. 2 is a sectional view parallel to the end face of the laser. This semiconductor optical element is a distributed feedback type semiconductor laser.

[0041] On a p-type InP substrate 10, a p-type InP cladding layer 12, an active layer 14 made of InGaAsP, an n-type InP cladding layer 16, and an n-type InP layer 18 are laminated in this order. A diffraction grating 20 is formed in the n-type InP cladding layer 16 and the n-type InP layer 18 along the optical waveguide direction. The diffraction grating 20 is formed by removing an InGaAsP layer having a PL wavelength of 1200 nm or more at predetermined intervals determined by the oscillation wavelength.

[0042] Mesa 22 which is a current narrowing structure is formed in p-type InP cladding layer 12 , acti...

Embodiment approach 2

[0060] FIG. 14 is a cross-sectional view showing a semiconductor optical element according to Embodiment 2. FIG. A waveguide 48 for extracting light emitted from the semiconductor laser 46 is integrated with the semiconductor laser 46 of the first embodiment.

Embodiment approach 3

[0062] FIG. 15 is a cross-sectional view showing a semiconductor optical element according to Embodiment 3. FIG. A semiconductor optical element 50 such as a semiconductor modulator or a semiconductor optical amplifier is integrated with the semiconductor laser 46 of the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com