Driving control method of low-loss hybrid stepping motor

A stepping motor, hybrid technology, applied in the direction of motor generator control, control system, electrical components, etc., can solve the problems of increasing power tube switching loss, increasing motor core loss, core heating, etc., to reduce drive Effects of system loss, reduction of hardware cost, and improvement of system efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

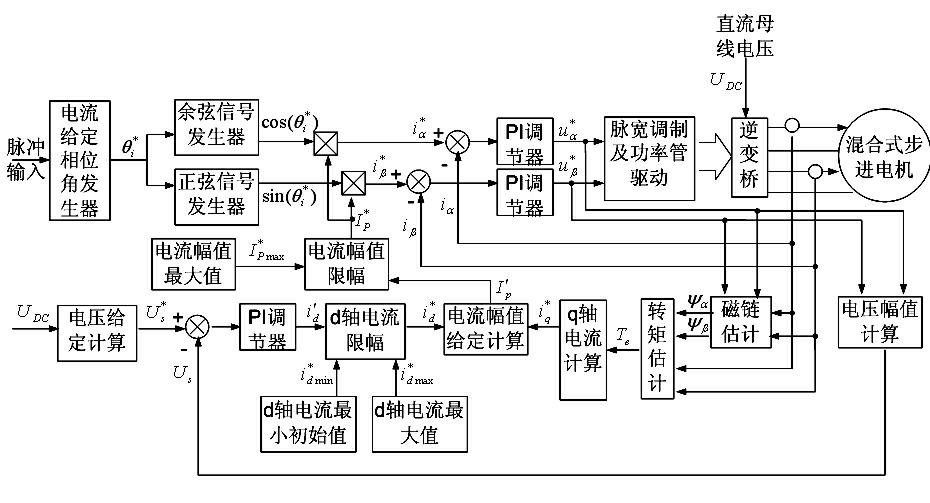

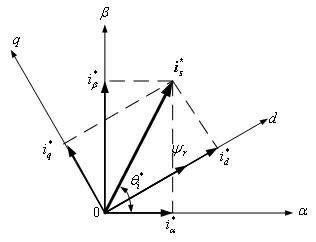

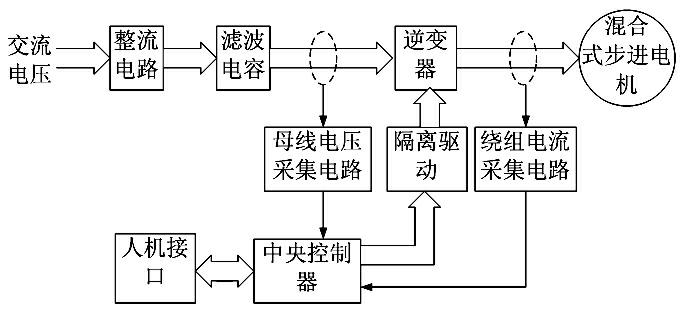

[0033] like figure 1 and figure 2 as shown, figure 1 is a system control principle block diagram of the present invention, figure 2 is the definition of coordinates and related vectors, and the winding current of the hybrid stepper motor can be decomposed into d-axis components in the rotor synchronous dq rotating coordinate system and the q-axis component ,in It is used to generate electromagnetic torque and drive external machinery, which belongs to active current; It is used to adjust the air gap flux linkage, which belongs to reactive current. Will By controlling to the lowest value, the winding current amplitude can be reduced to the minimum value, thereby reducing the winding copper loss, core iron loss and power tube switching loss to the minimum. Please continue to refer to figure 1 ,Depend on figure 1 It can be seen that the input pulse is sent to the current given phase angle generator to obtain the current given phase angle ; Simultaneously send co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com