Asymmetrical 980nm semiconductor laser structure with high power and wide waveguide

An asymmetric laser technology, applied in the structure of optical waveguide semiconductors, semiconductor lasers, lasers, etc., can solve the problems of increasing device threshold current and series resistance, leaking high-order transverse modes, and limiting high-power output of lasers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

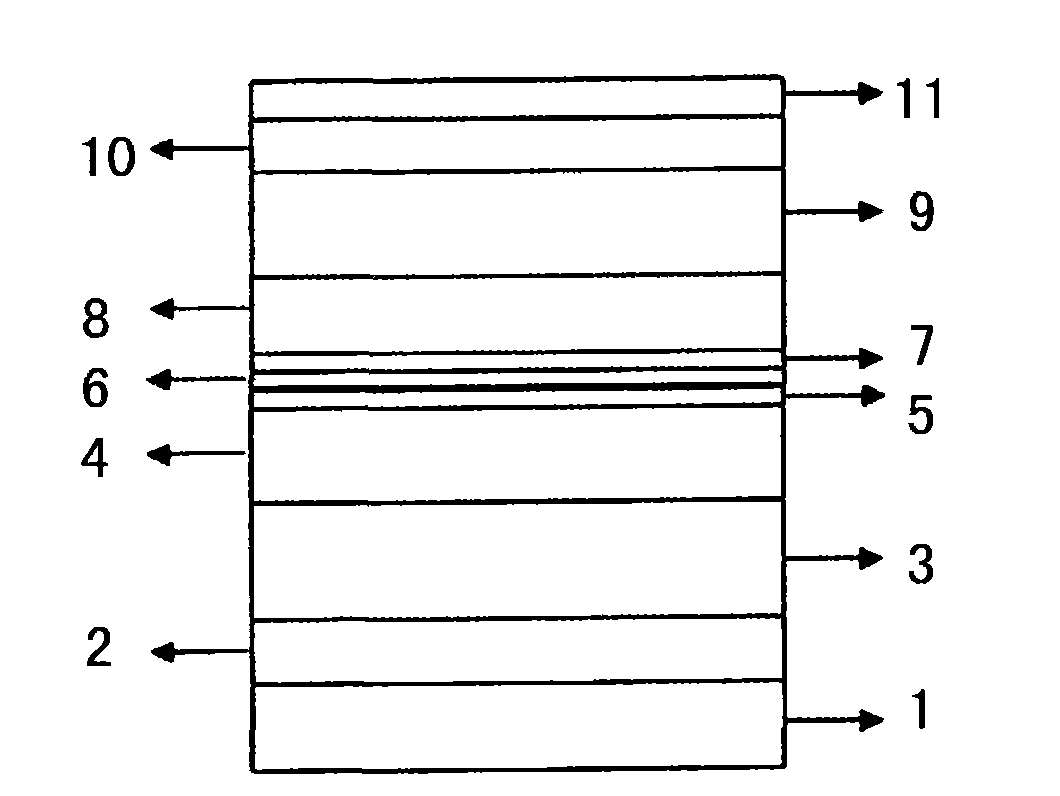

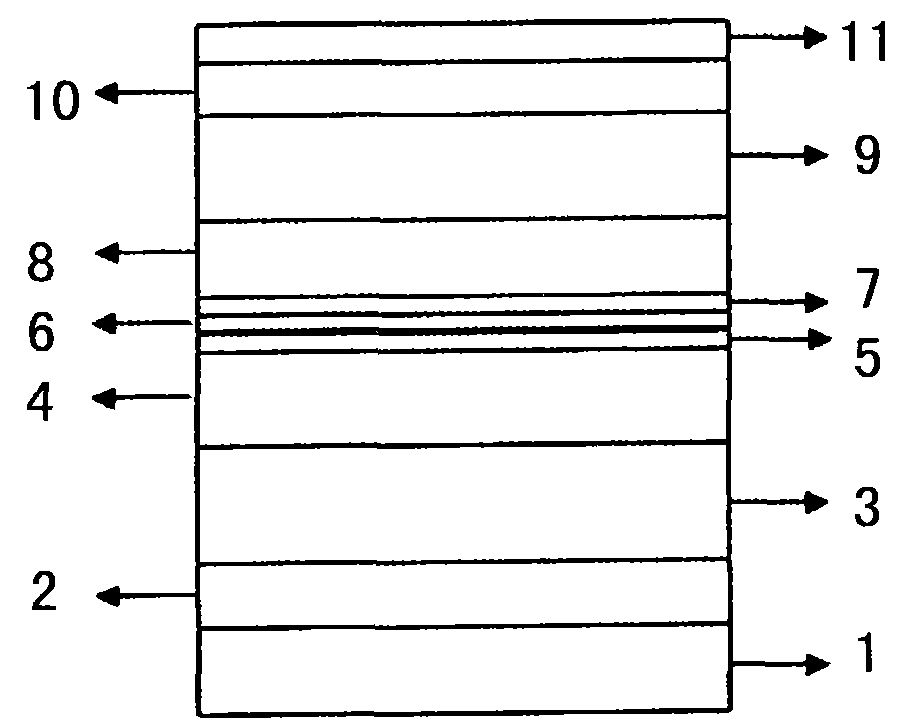

[0024] Combine below figure 1 Describe in detail the structural details of a high-power asymmetric wide-waveguide 980nm semiconductor laser according to a specific embodiment of the present invention.

[0025] refer to figure 1 , a high-power asymmetric wide waveguide 980nm semiconductor laser structure of the present invention, comprising:

[0026] A substrate 1, which is an N-type gallium arsenide material on the (100) plane, and the substrate 1 is used to epitaxially grow various layers of materials of the laser thereon;

[0027] A buffer layer 2, the buffer layer 2 is made of N-gallium arsenic material, the buffer layer 2 is fabricated on the substrate 1, and is mainly used to adjust the lattice fit;

[0028] An N-type lower confinement layer 3 is made of N-AlGaAs material, and the N-type lower confinement layer 3 is fabricated on the buffer layer 2;

[0029] The lower waveguide layer 4 is made of N-AlGaAs material, and the lower waveguide layer 4 is made on the lower c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com