Method for processing low-salt air-dried golden pork knuckles

A processing method and golden hoof technology, which can be used in applications, food preparation, climate change adaptation, etc., can solve the problems of low salt content and difficulty in satisfying people's tastes, and achieve comfortable taste, protect meat color, and inhibit the formation of nitrosamines Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

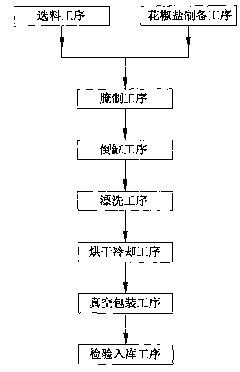

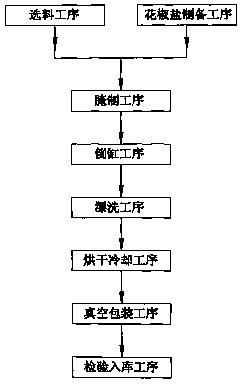

[0026] see figure 1 , the processing method of low-salt air-dried golden hooves in this embodiment includes a material selection process, a pepper salt preparation process, a pickling process, a vat inversion process, a rinsing process, a drying and cooling process, a vacuum packaging process, and an inspection and storage process. In the material process, the pig’s trotters of the front elbow are selected. The pig’s trotters start from the wrist joint and are 6cm away from the elbow joint. The divided pig’s trotters have a flat structure. Cutting surface and a cutting surface with a small diameter, the height of the whole pig’s trotter shoulder is 6cm, and the leather surface on the pig’s trotter shoulder is 2.5cm longer than the two cross-sections, then remove the residual hair on the skin of the pig’s trotter shoulder, and clean the surface For the black spots, the two ends of the pig’s trotters are sawed flat to expose the pork bones, and the skin of the pig’s trotters is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com