Preparation method of traditional Chinese medicine ultrafine formula particles

A technology of formula granules and traditional Chinese medicine, which is applied in pharmaceutical formulas, medical preparations containing active ingredients, medical raw materials derived from ferns/filamentous plants, etc. problems such as low rate, to achieve the effect of shortening extraction time, advanced production technology, and high technological content of products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Get 3950kg of dog ridge medicinal material, first process it into decoction pieces, then crush it into coarse powder, and sterilize it for subsequent use. Take 100g of coarse powder, adopt the superfine pulverization method, pulverize for 25 minutes to obtain dog spine superfine powder, and add water to the remaining 3850g of coarse powder for dynamic extraction twice, add water for the first extraction for 2 hours, add water for the second extraction for 1.5 hours, and extract the temperature Both are 80°C. The extract is sucked into the external circulation decompression concentrator, the vacuum degree is controlled between -0.06~-0.08MPa, the temperature is controlled at 70~80°C and concentrated under reduced pressure to a clear paste with a relative density of about 1.15 (measured at 60°C). Turn on the air inlet heater until the air inlet temperature reaches 160-180°C and the outlet temperature is 80-100°C, open the feed valve to feed the material, and spray dry to ...

Embodiment 2

[0034] Take 4160g of amomum medicinal material, first process it into decoction pieces, crush it into the coarsest powder, and sterilize it for later use. Take 100g of the coarse powder and adopt the superfine pulverization method to obtain superfine powder of amomum, add water to distill and extract the remaining 4060g for 6 hours, collect volatile oil, medicine liquid separately. Add β-cyclodextrin to the volatile oil, and adopt the saturated aqueous solution method for clathration. The specific operation steps are: take 4 times the amount of β-cyclodextrin, add water, heat to dissolve, and place it on a magnetic stirrer after cooling, at a constant temperature of 50°C. Add volatile oil (the volatile oil is formulated with ethanol in advance as an ethanol solution containing 50% volatile oil), stir for 3 hours, cool, refrigerate at 2-10°C for 24 hours, dry at 50°C, pass through 80 mesh, and set aside. Add water to the dregs after extracting volatile oil, extract dynamically ...

Embodiment 3

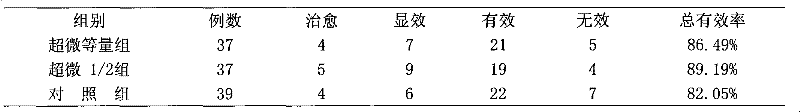

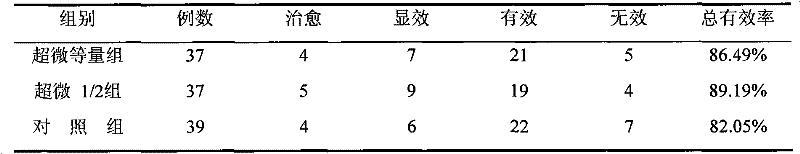

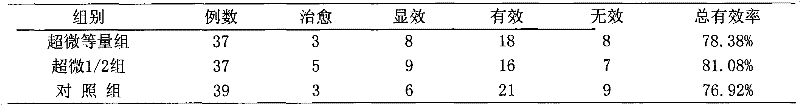

[0045] In order to prove the advantages of the present invention, a preliminary observation and study on the clinical curative effect of Kaiwei Jinshifang composed of 15 single-flavor ultrafine formula granules such as Ming Codonopsis, Atractylodes macrocephala, Poria cocos, and Fa Pinellia on the syndrome of fullness due to weakness of the spleen and stomach was carried out. The above 15 Chinese herbal medicines are separately prepared into ultrafine particles through the steps of ultrafine and extraction, and then the dosage is proportioned according to the traditional prescription.

[0046] To preliminarily observe the clinical curative effect and clinical safety of Kaiwei Jinshi Decoction Superfine Formula Granules on spleen and stomach weakness type fullness syndrome, and understand its curative effect on chronic superficial gastritis, functional dyspepsia and bile reflux esophagitis, etc. Effects on gastrointestinal motility.

[0047] Randomized, single-blind controlled ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com