Perovskite catalyst used for steam reforming of oxygenated ethanol and preparation method thereof

A technology for steam reforming and oxygenating ethanol, applied in chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, etc. problem, to achieve the effect of less carbon deposition and high activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0014] Weigh 2.576g of La(NO 3 ) 3 .6H 2 O, 2.391g of Fe(NO 3 ) 3 .9H 2 O, 0.621g Ca(NO 3 ) 2 4H 2 O, 0.747g Ni(NO 3 ) 2 .6H 2 O, the citric acid of 5.63g, the polyethylene glycol 400 of 0.3g, join the deionized water of 150ml and be made into solution, stir 5 hours in the oil bath of temperature 50 ℃, stirring rate 120rpm, obtain uniform liquid at 90 Continue stirring in an oil bath at °C until a sol is obtained. It was then dried at 120° C. for 24 hours. The obtained solid was roasted in a roasting furnace. The roasting process was as follows: heating to 400° C. at a heating rate of 2° C. / min, roasting for 3 hours, and then heating to 750° C. at the same heating rate, and roasting for 6 hours. Get 3g of La 0.7 Ca 0.3 Fe 0.7 Ni 0.3 o 3 . The obtained solid is ground and sieved into 40-60 mesh particles.

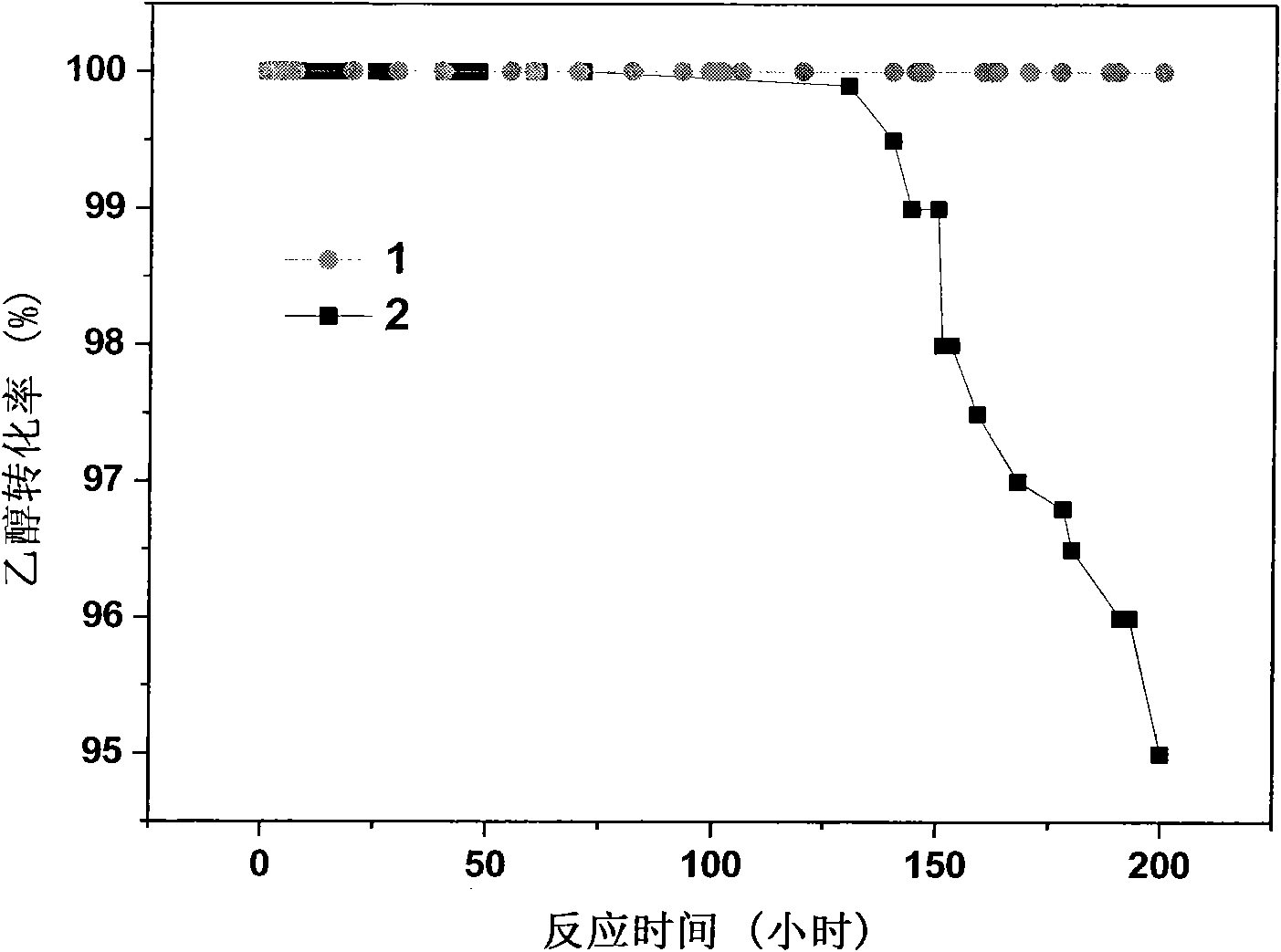

[0015] Example 1 The catalyst prepared in the process of producing hydrogen-rich gas by oxygenated ethanol steam reforming: the performance test of the ca...

Embodiment 2

[0019] La 0.5 Ca 0.5 Fe 0.7 Ni 0.3 o 3 The preparation process is the same as in Example 1, except that the raw material consumption is different: the raw material consumption is respectively: 1.84g of La(NO 3 ) 3 .6H 2 O, 2.391g of Fe(NO 3 ) 3 .9H 2 O, 1.035g Ca(NO 3 ) 2 4H 2 O, 0.747g Ni(NO 3 ) 2 .6H 2 O, the citric acid of 5.63g, the polyethylene glycol 400 of 0.3g, mix and dissolve in deionized water and make solution, subsequent steps are with embodiment 1.

[0020] The prepared catalyst is used in the process of producing hydrogen-rich gas by oxygenated ethanol steam reforming: the molar ratio of ethanol to water is 1:3, and enter the reactor to start the reaction after being vaporized in the gasification chamber at 140°C. The gas composition is 80vol% nitrogen + oxygen, 20vol% ethanol + water, wherein the molar ratio of ethanol to water is 1:3, and the molar ratio of oxygen to ethanol is 0.5:1, at 120000h -1 The reaction was carried out at space velocity. ...

Embodiment 3

[0022] La 0.6 Ca 0.4 Fe 0.7 Ni 0.3 o 3 The preparation process is the same as in Example 1, except that the raw material consumption is different: the raw material consumption is respectively: 2.208g of La(NO 3 ) 3 .6H 2 O, 2.391g of Fe(NO 3 ) 3 .9H 2 O, 0.828g of Ca(NO 3 ) 2 4H 2 O, 0.747g Ni(NO 3 ) 2 .6H 2 O, the citric acid of 5.63g, 0.3g polyethylene glycol 400, mix and dissolve in deionized water and make solution, subsequent steps are with embodiment 1.

[0023] The prepared catalyst is used in the process of producing hydrogen-rich gas by oxygenated ethanol steam reforming: the molar ratio of ethanol to water is 1:3, and enter the reactor to start the reaction after being vaporized in the gasification chamber at 140°C. The gas composition is 80vol% nitrogen + oxygen, 20vol% ethanol + water, wherein the molar ratio of ethanol to water is 1:3, and the molar ratio of oxygen to ethanol is 0.5:1, at 120000h -1 The reaction was carried out at space velocity. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com