Casting method of low-alloy hydraulic pump stator casting

A low-alloy, pump stator technology, applied in the direction of casting molding equipment, casting molds, furnace types, etc., can solve problems such as metallographic structure not up to standard

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] Taking the casting of low alloy CC1021S hydraulic pump stator casting as an example, the casting method includes the following steps:

[0045] (1) Sand mixing molding

[0046] The sand mixing process is to mix clay green sand in the sand treatment system, and the mixed sand is transported to the side of the molding machine by a trolley for molding; then the molds made by the microseismic compaction molding machine are arranged in the pouring area Inside, wait for the molten iron to pour.

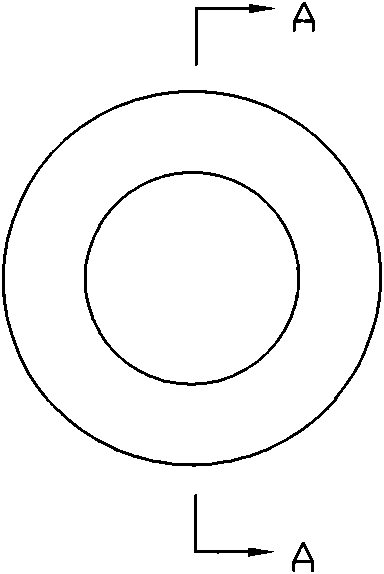

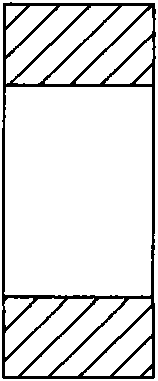

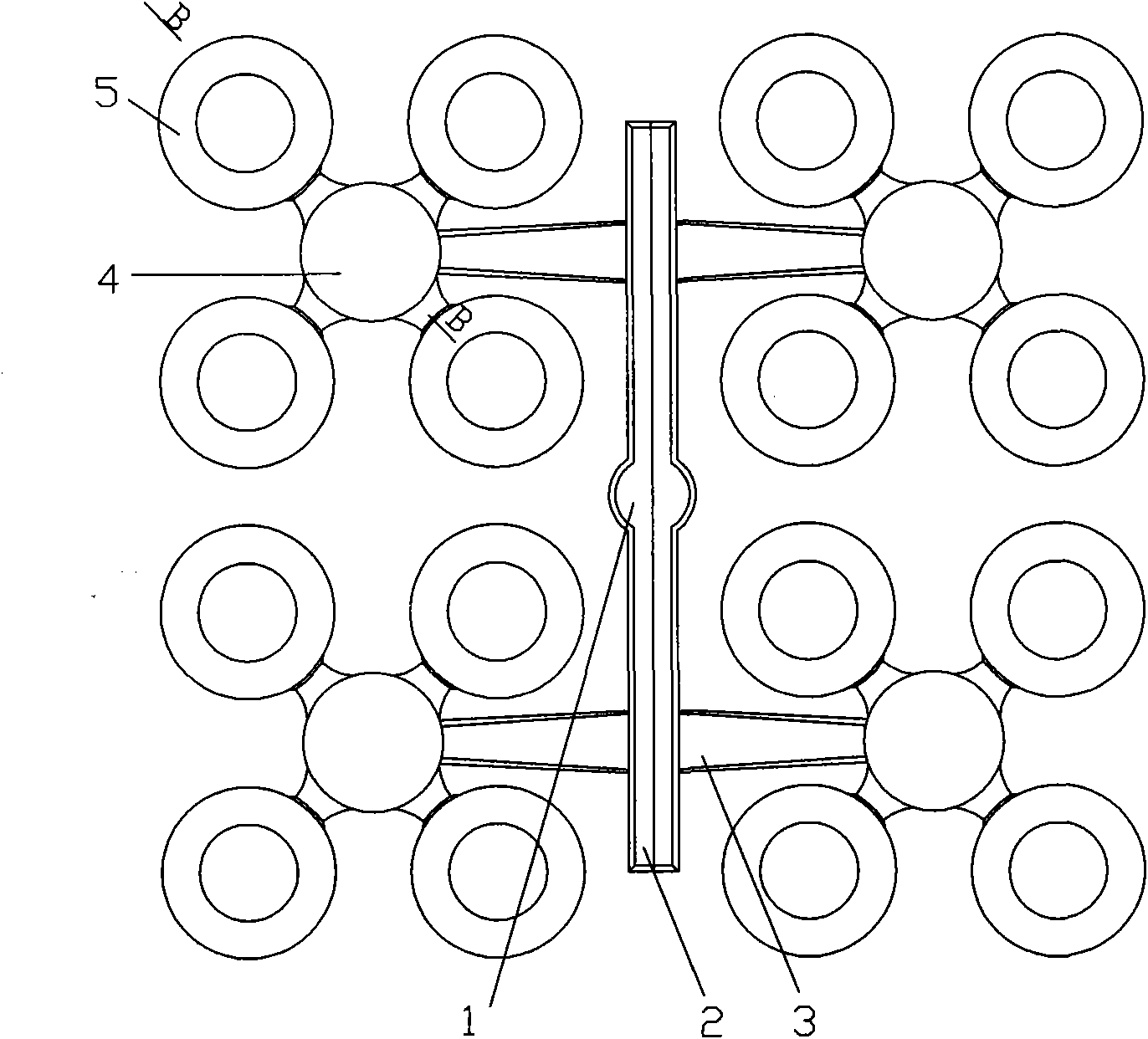

[0047] For the molding process, please refer to the rough drawing of the low alloy CC1021S hydraulic pump stator casting of the present invention figure 1 , figure 2 , the structure of the stator casting is relatively simple, and the blank is uniform. It is decided to use a microseismic compaction and unboxing molding machine for molding production. The sand mold size is 390×40×100 / 100, and 16 castings are placed in each mold. For the mold plate process diagram, please refer to i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com