Double-path circulation full-mixing type anaerobic reactor

An anaerobic reactor and reactor technology, applied in the field of anaerobic biological treatment, can solve problems such as excessive stirring power, intolerance to suspended solids, uneven distribution, etc., achieve good mass transfer effect, reduce operating costs, and shorten the production period high rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

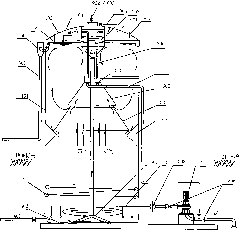

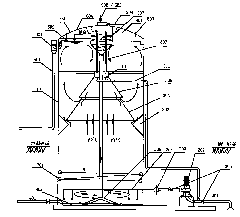

[0034] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0035] The two-way circulating fully mixed anaerobic reactor of the present invention mainly includes: a reactor main body, a feeding device, a circulating stirring device, a sewage discharge device, a safety protection device, a water outlet device, a heating device, a detection control device, and a biogas collection device and so on.

[0036] The entire anaerobic reactor is a cylindrical steel structure or reinforced concrete structure, which adopts a semi-underground design, and the bottom of the reactor is buried underground.

[0037] Wherein, the reactor main body is a complete cylindrical closed tank, which is composed of a tank body 101 and a tank top head 102; other components of the reactor depend on the reactor main body.

[0038] Wherein, the feeding device adopts a swirl feeding method, and the feeding device inc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com