Beta-cyclodextrin derivative complex nucleating agent and application thereof in polypropylene

A technology of derivatives and cyclodextrin, which is applied in the field of high-performance polymer materials, can solve the problems of poor modification performance and high cost, and achieve the effects of improving impact strength, easy access to raw materials, and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

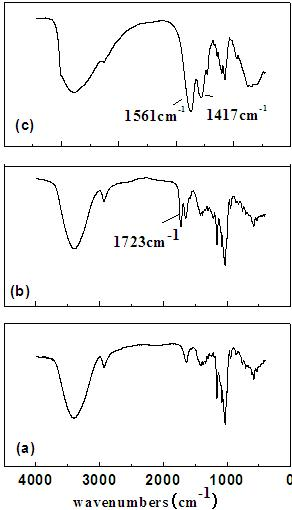

[0014] The specific steps of the preparation method of the β-cyclodextrin-maleic anhydride derivative complex nucleating agent are as follows:

[0015] (1) Synthesis of β-cyclodextrin-maleic anhydride derivatives: Dissolve β-cyclodextrin and maleic anhydride with a molar mass ratio of 1:6~1:12 in a solvent N'N- In dimethylformamide DMF, react at 60~80°C for 8~10h; after the reaction, cool down to room temperature, add chloroform with the same volume as DMF to precipitate out; the volume ratio for precipitation is 100:2~100 : 5 mixed solvents of acetone and water were washed several times, vacuum-dried after suction filtration, and obtained β-cyclodextrin-maleic anhydride derivatives;

[0016] (2) Synthesis of β-cyclodextrin-maleic anhydride derivative complex nucleating agent: dissolve lanthanum oxide in hydrochloric acid with a molar mass ratio of 5 to 7 times to form a lanthanum trichloride solution, filter and store in an evaporating dish Heat and condense into lanthanum t...

Embodiment 1

[0020] Dissolve 0.01mol β-cyclodextrin and 0.1mol maleic anhydride in 50ml of N'N-dimethylformamide DMF and react at 70°C for 9~10h; , so that the precipitate is separated out; the precipitate is washed several times with a mixed solvent of acetone and water with a volume ratio of 100:3 to 100:4, vacuum-dried after suction filtration to obtain a β-cyclodextrin-maleic anhydride derivative;

[0021] Dissolve 1 mol of lanthanum oxide in 6 mol of hydrochloric acid to form lanthanum trichloride solution, filter and heat and concentrate in an evaporating dish to form lanthanum trichloride powder; dissolve 0.01 mol of β-cyclodextrin-maleic anhydride derivative in 100 ml of water, add 0.12mol of lanthanum trichloride powder, stirred and reacted for 1~2h to dissolve it completely; added 0.36mol of triethylamine, reacted for 12~13h to obtain a light yellow precipitate; the precipitate was washed several times with water and ethanol after suction filtration, and vacuum dried Obtain β-cyc...

Embodiment 2

[0024] 1Kg polypropylene and 0.2~0.5wt% β-CD-MAH-La are uniformly mixed in a high-speed mixer, extruded and granulated in a twin-screw extruder at 175~220°C, and injected at 170~210°C into The standard spline is denoted as PP1.

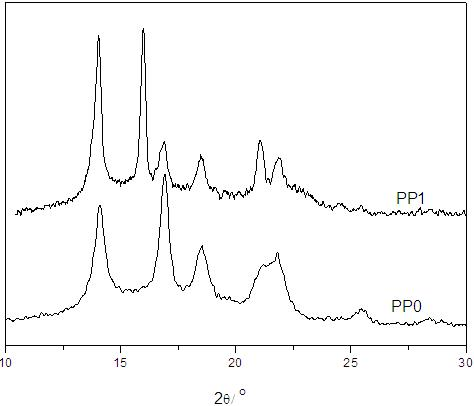

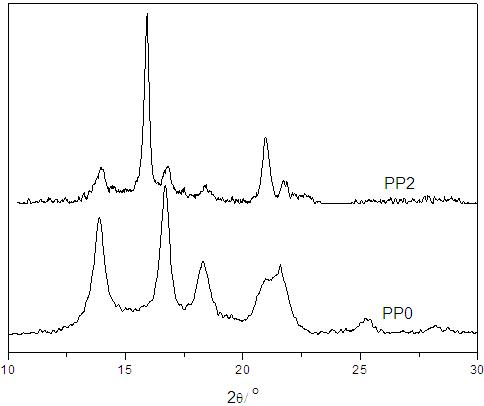

[0025] Test impact performance according to GB / T1043-93 standard, test heat distortion temperature according to GB / T1634-2004 standard, measure tensile properties according to GB / T1040.2-2006 and measure bending properties according to GB / T9341-2008, the test results are shown in the table 1. The samples were scanned with WAXD. In the WAXD spectrum, the main diffraction peaks of the α-PP crystal form are at 2θ of 14.1° (110), 16.9° (040), and 18.5° (130), corresponding to (110), (040), ( 130) crystal plane, and the typical β-PP crystal form is the (300) crystal plane diffraction peak at 16.1°.

[0026] The blank PP is also made into a standard spline according to the above process, which is recorded as PP0 for testing, so as to facilitate compariso...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com