Method for preparing cross-linked polytetrafluoroethylene through electron beam irradiation

A technology of polytetrafluoroethylene and electron beam irradiation is applied in the field of preparing cross-linked polytetrafluoroethylene, which can solve the problems of lowering crystallinity, lowering melting point and keeping mechanical properties unchanged.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

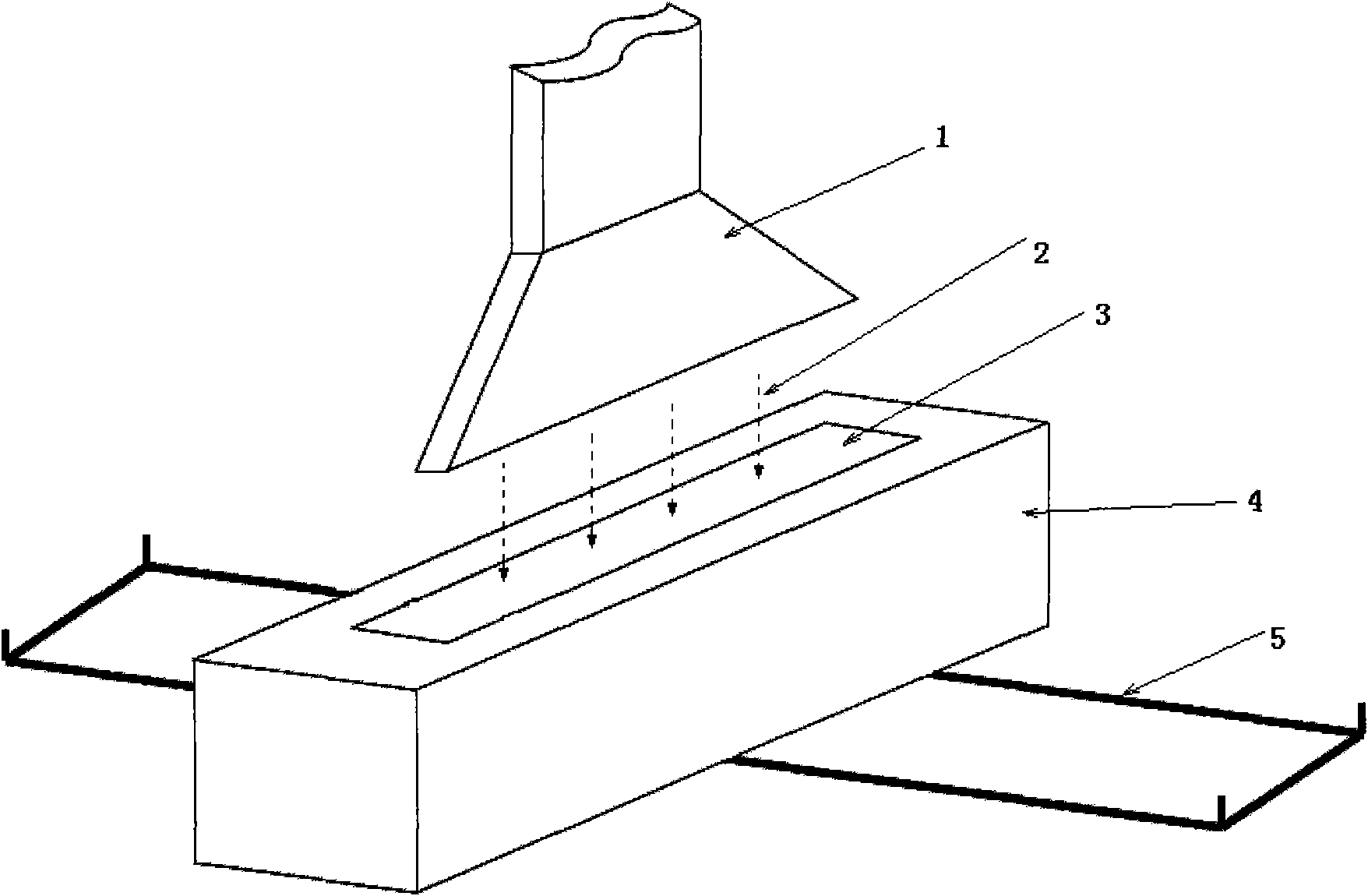

Method used

Image

Examples

Embodiment 1

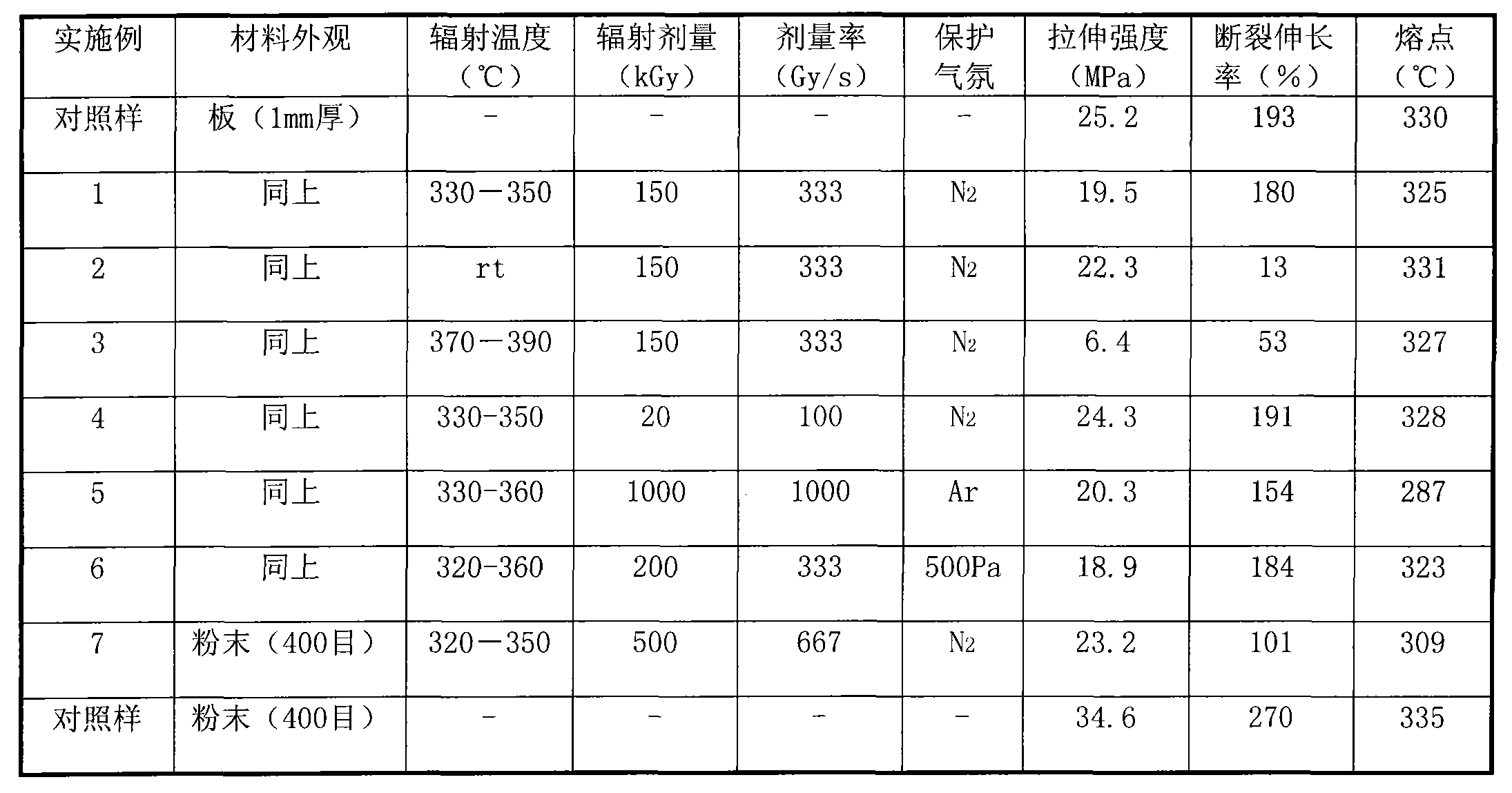

[0032] According to the above implementation procedure, the irradiated sample is a 1mm thick PTFE sheet, the electron beam energy is 1.6MeV, the inert gas is 1atm nitrogen, the dose rate is 333Gy / s, the radiation time is 7.5min, and the total radiation dose is 150kGy, radiation temperature 330~350℃, the properties of the obtained radiation cross-linked polytetrafluoroethylene and non-radiated polytetrafluoroethylene are listed in Table 1. Among them, the performance of the non-irradiated PTFE sheet is listed in Table 1 for comparison testing.

Embodiment 2

[0034] According to the above implementation procedure, the irradiated sample is a 1mm thick PTFE sheet, the electron beam energy is 1.6MeV, the inert gas is 1atm nitrogen, the dose rate is 333Gy / s, the radiation time is 7.5min, and the total radiation dose is 150kGy, the radiation temperature is room temperature, and the properties of the obtained radiation polytetrafluoroethylene are listed in Table 1.

Embodiment 3

[0036] According to the above implementation procedure, the irradiated sample is a 1mm thick PTFE sheet, the electron beam energy is 1.6MeV, the inert gas is 1atm nitrogen, the dose rate is 333Gy / s, the radiation time is 7.5min, and the total radiation dose is 150kGy, the radiation temperature is 330~350℃, and the properties of the radiation crosslinked polytetrafluoroethylene are listed in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com