Special coating resisting 400 DEG C to 0 DEG C high and low temperature alternative transient variations

A high and low temperature alternating and special technology, applied in the direction of coating, etc., can solve the problems of no breakthrough in the performance of high and low temperature difference alternating transients, can not meet the requirements of special application sites, increase the resistance to high and low temperature alternating transients, etc., to achieve good heavy defense Corrosion performance, tight adhesion, convenient processing and use

Active Publication Date: 2012-11-21

NINGBO FEILUN PAINT MFG

View PDF1 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0004] In the patent application "Organosilicon High Temperature Resistant Coating" with the publication number CN1560156A, the so-called organosilicon high temperature resistant paint is only an ordinary heat-resistant paint. From the perspective of components, it does not use special additives to promote the combination. The technical index is only a single heat resistance, and there are no measures and performance breakthroughs to withstand the alternating transients of high and low temperature differences

[0005] Although the patent application with the publication number CN101671522A "Special High Temperature Resistant Coatings for Transport Vehicles and Its Preparation Method" also has certain heat resistance, it does not add similar special additives in principle to increase the resistance to high and low temperature differences. In addition, the minimum temperature of its "temperature difference cycle test" is only 23°C, and the number of cycles is only 4 times, which still cannot meet the requirements of many special application places.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

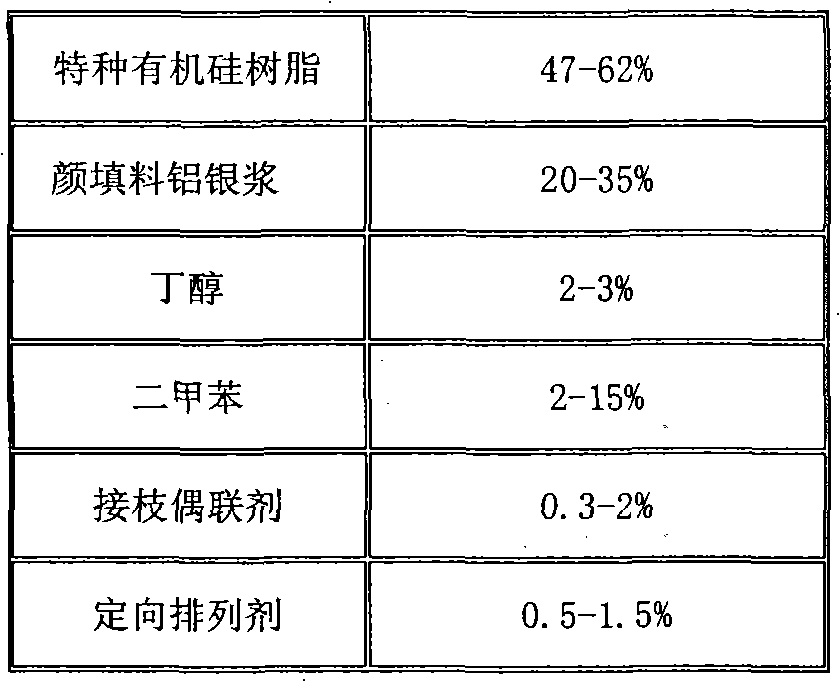

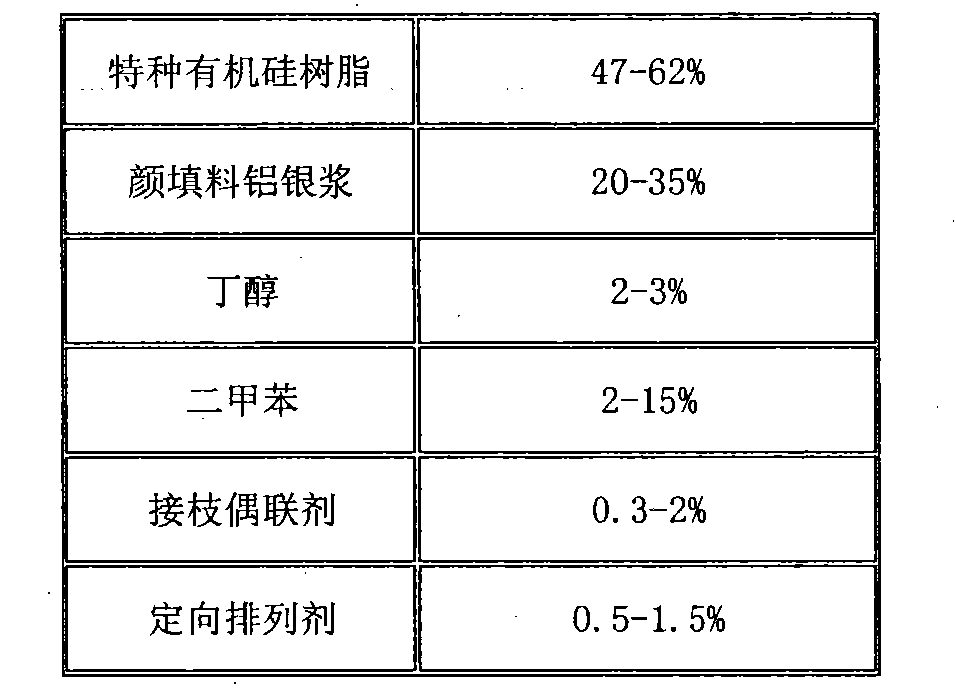

specific Embodiment 1

[0022]

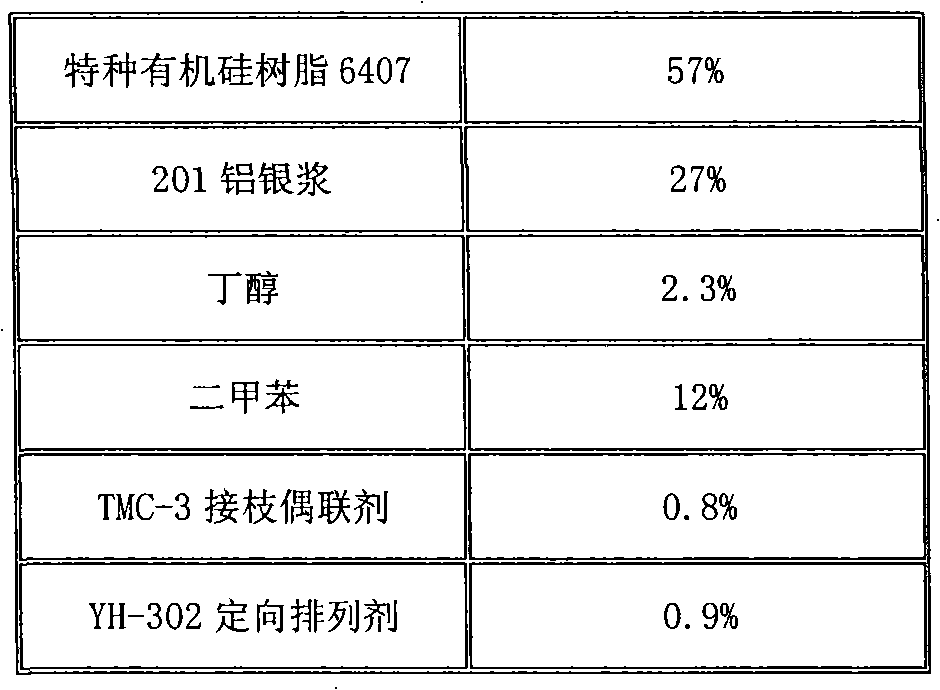

specific Embodiment 2

[0023]

[0024]

[0025] Because YH-302 and SG-205 aluminum powder are used as alignment agents, it has a good alignment effect in metal coatings, easy dispersion, and good thermal stability, which can prevent pigments from settling and agglomerating without increasing viscosity.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention relates to a special coating resisting 400 DEG C to 0 DEG C high and low temperature alternative transient variations. After being coated on a metal surface, the coating has the characteristics of self-drying at room temperature, 400 DEG C high temperature resistance and 400 DEG C to 0 DEG C high and low temperature alternative transient variations resistance. A one-component silicone resin system is utilized and the following components are weighted by weight percent: 47-62% of special silicone resin, 20 to 35% of pigment aluminum paste, 2 to 3% of methanol, 2 to 15% of xylene,0.3 to 2% of graft coupling agent and 0.5 to 1.5% of orientation arrangement agent, and the coating is prepared by evenly stirring the above materials at a high speed; aluminum powder used as the orientation arrangement agent has good thermal stability, can prevent pigment precipitation and hard lump formation and does not increase viscosity; the coating achieves a breakthrough in performance through the reasonable collocation of special addition agent with resin and pigments, can withstand more than 20 times of dual effects of temperature difference alternative transient variations of an icewater mixture from 400 DEG C to 0 DEG C, is particularly suitable for serving as protective paint on the metal surface of large-scale equipment and workpieces which can not be baked or are inconvenient to be moved, and has the same production and construction processes as common coatings, and convenient processing and use.

Description

technical field [0001] The invention relates to a single-component normal temperature self-drying special coating with high temperature resistance and high and low temperature alternating transient resistance and its production process. After the coating is painted on the metal surface, it can withstand high temperature of 400°C for a long time and high and low temperature alternating transient of 400°C-0°C. Background technique [0002] With the rapid improvement of social and economic development requirements, coatings have begun to assume unique functions in various special occasions. Traditional high-temperature-resistant coatings are divided into two categories. One type is composed of resin and curing agent (two-component or multi-component). Although it can achieve normal temperature self-drying, the high temperature resistance is greatly affected by the curing agent. The second type is It cannot be self-dried at room temperature, and it needs to be baked at high tem...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): C09D183/00C09D7/12C09D5/00

Inventor 袁泉利蓝席建冯伟东朱能杰潘神燕

Owner NINGBO FEILUN PAINT MFG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com