CdxZn1-xS/ZnS ternary core-shell quantum dot and method for preparing same

A technology of cdxzn1-xs and core-shell quantum dots, applied in chemical instruments and methods, luminescent materials, etc., can solve the problems of difficult synthesis of quantum dots, cumbersome preparation process, unpredictability, etc., to optimize the cladding operation process, The effect of simplifying the preparation process and expanding the application space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

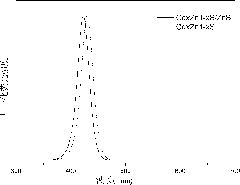

Embodiment 1

[0038] In the first step, weigh 128.2mg (1.0mmol) CdO and 898.2mg (11.0mmol) ZnO in a three-necked flask, and add 7.5mL (24mmol) oleic acid and 16mL (48mmol) ODE, under magnetic stirring and argon Under the condition of protection, heating to complete dissolution, so that CdO and ZnO are completely dissolved to obtain a mixed precursor solution of Cd and Zn with a specific molar ratio composition.

[0039] In the second step, weigh 48.3mg (1.5mmol) of S powder into a three-necked flask, add 1.5mL (4.5mmol) of ODE, and raise the temperature to 150°C to completely dissolve the S powder to obtain S precursor solution A; 336.4mg (10.5mmol) of S powder was dissolved in 3.5mL (7.9mmol) of TOP, and the S powder was completely dissolved by ultrasonic to obtain S precursor solution B.

[0040] In the third step, under the protection of argon, heat the Cd and Zn mixed precursor solution obtained in the first step to 310 °C, and then quickly inject the S precursor solution A obtained in ...

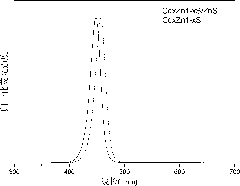

Embodiment 2

[0044] In the first step, weigh 128.2mg (1.0mmol) CdO and 815.3mg (10.0mmol) ZnO in a three-necked flask, and add 7.0mL (22mmol) oleic acid and 14mL (44mmol) ODE, under magnetic stirring and argon Under the condition of protection, heating to complete dissolution, so that CdO and ZnO are completely dissolved to obtain a mixed precursor solution of Cd and Zn with a specific molar ratio composition. In the second step, weigh 48.3mg (1.5mmol) of S powder into a three-necked flask, add 2.0mL (6mmol) of ODE, and raise the temperature to 150°C to completely dissolve the S powder to obtain S precursor solution A; in the glove box Dissolve 304.2 mg (9.5 mmol) of S powder in 5.5 mL (12.0 mmol) of TBP, and ultrasonically dissolve the S powder completely to obtain S precursor solution B.

[0045] In the third step, under the protection of argon, heat the Cd and Zn mixed precursor solution obtained in the first step to 310°C, and then quickly inject the S precursor solution A obtained in ...

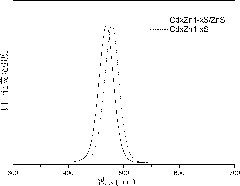

Embodiment 3

[0049] The first step, weigh 128.2mg (1.0mmol) CdO and 407.3mg (5.0mmol) ZnO and place in a three-necked flask, and add 3.8mL (12mmol) oleic acid and 8.0mL (24mmol) ODE, under magnetic stirring and argon Under the condition of gas protection, heat until completely dissolved, so that CdO and ZnO are completely dissolved to obtain a mixed precursor solution of Cd and Zn with a specific molar ratio composition.

[0050] In the second step, weigh 48.3mg (1.5mmol) of S powder into a three-necked flask, add 2.5mL (7.5mmol) of ODE, and raise the temperature to 150°C to completely dissolve the S powder to obtain S precursor solution A; Dissolve 80.3mg (4.5mmol) of S powder in 2mL (4.5mmol) of TOP, and ultrasonically dissolve the S powder completely to obtain S precursor solution B.

[0051] In the third step, under the protection of argon, heat the Cd and Zn mixed precursor solution obtained in the first step to 310°C, and then quickly inject the S precursor solution A obtained in the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com