Dyeing method

A dyeing method and fabric technology, applied in the field of dyeing and finishing, can solve the problems of low dye uptake and poor UV resistance, and achieve the effects of enhanced binding ability, good wash fastness, and broad application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] A dyeing method, comprising the steps of:

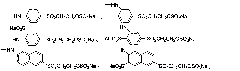

[0034] 1) Modification of cellulose fabrics with reactive UV absorbers for cellulose with anionic groups:

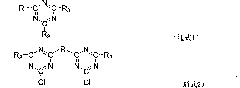

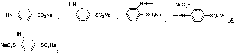

[0035] (The structural formula of the UV absorber is Dosage 3% (owf); liquid ratio 1:10, the concentration of Yuanming powder in the modified liquid is 3wt%)

[0036] Disperse 30g of Yuanming powder and 3g of UV absorber into water to prepare 1000ml of modified solution; take 100g of cotton fabric and soak in the modified solution for 15min, then raise the temperature to 30℃ at a rate of 2℃ / min, keep it warm for 50min and divide it in batches Add soda ash, the concentration of soda ash in the modified solution is controlled at 3-10g / L, wash with water after the heat preservation is completed.

[0037] 2) Dye the modified fabric with berberine: (berberine 0.1% (owf), liquid ratio 1: 4)

[0038] Dissolve 0.1g of berberine in water to prepare 400ml of dyeing liquor, put the modified cotton fabric into the dyeing liquor ...

Embodiment 2

[0040] A dyeing method, comprising the steps of:

[0041] 1) Modification of cellulose fabrics with reactive UV absorbers for cellulose with anionic groups:

[0042] (The structural formula of the UV absorber is The dosage is 4% (owf); the liquid ratio is 1:20, and the concentration of Yuanming powder in the modified liquid is 10wt%)

[0043] Disperse 200g of Yuanming powder and 4g of UV absorber into water to prepare 2000ml of modified solution; take 100g of cotton fabric and soak in the modified solution for 20min, then raise the temperature to 60℃ at a rate of 3℃ / min, keep it warm for 40min and divide it in batches Add soda ash (the concentration of soda ash in the modification solution is controlled at 3-10g / L), and wash with water after the heat preservation is completed.

[0044] 2) Dye the modified fabric with berberine: (berberine 0.5% (owf), liquid ratio 1: 10)

[0045] Dissolve 0.5g of berberine in water to prepare 1000ml of dyeing liquor. Put the modified cotton...

Embodiment 3

[0047] A dyeing method, comprising the steps of:

[0048] 1) Modification of cellulose fabrics with reactive UV absorbers for cellulose with anionic groups:

[0049] (The structural formula of the UV absorber is Amount of 5% (owf); liquid ratio 1:30, the concentration of Yuanming powder in the modified liquid is 8wt%)

[0050] Disperse 240g of Yuanming powder and 5g of UV absorber into water to prepare 3000ml of modified liquid; put 100g of cotton fabric into the modified liquid and soak for 10min, then raise the temperature to 50°C at a speed of 1°C / min, keep it warm for 30min and divide it in batches Add soda ash (the concentration of soda ash in the modification solution is controlled at 3-10g / L), and wash with water after the heat preservation is completed.

[0051] 2) Dye the modified fabric with berberine: (berberine 1% (owf), liquid ratio 1: 15)

[0052] Dissolve 1g of berberine in water to prepare 1500ml of dyeing liquor, put the modified cotton fabric into the dye...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com