Method for optimizing chromatograph operating parameters of simulated mobile bed

A technology for simulating moving bed and chromatographic operation, which is applied in the field of simulating moving bed chromatographic operation parameter optimization, which can solve the problems of small number of operating points, poor applicability, and inability to quantitatively study, and achieve better optimization results and reduce optimization costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

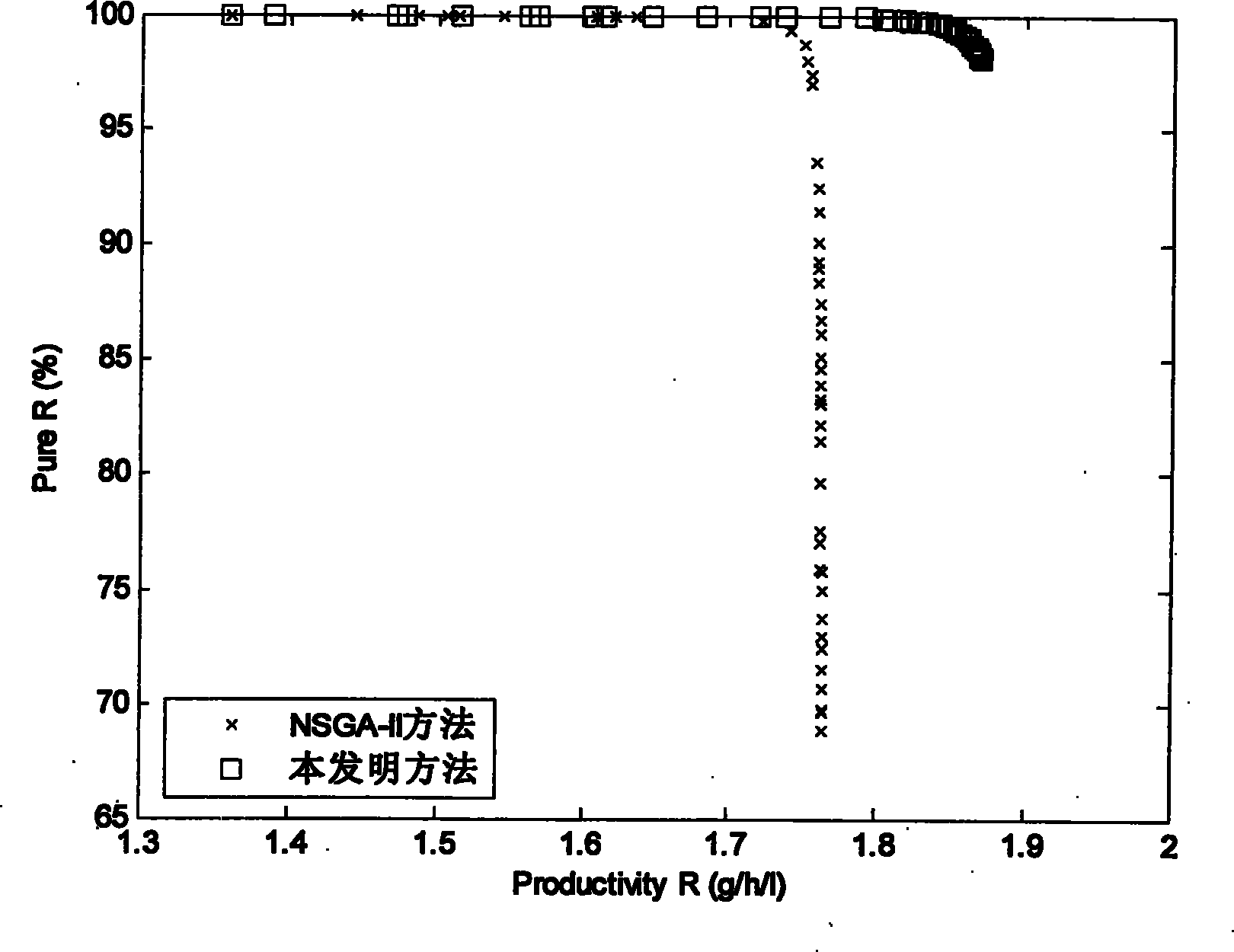

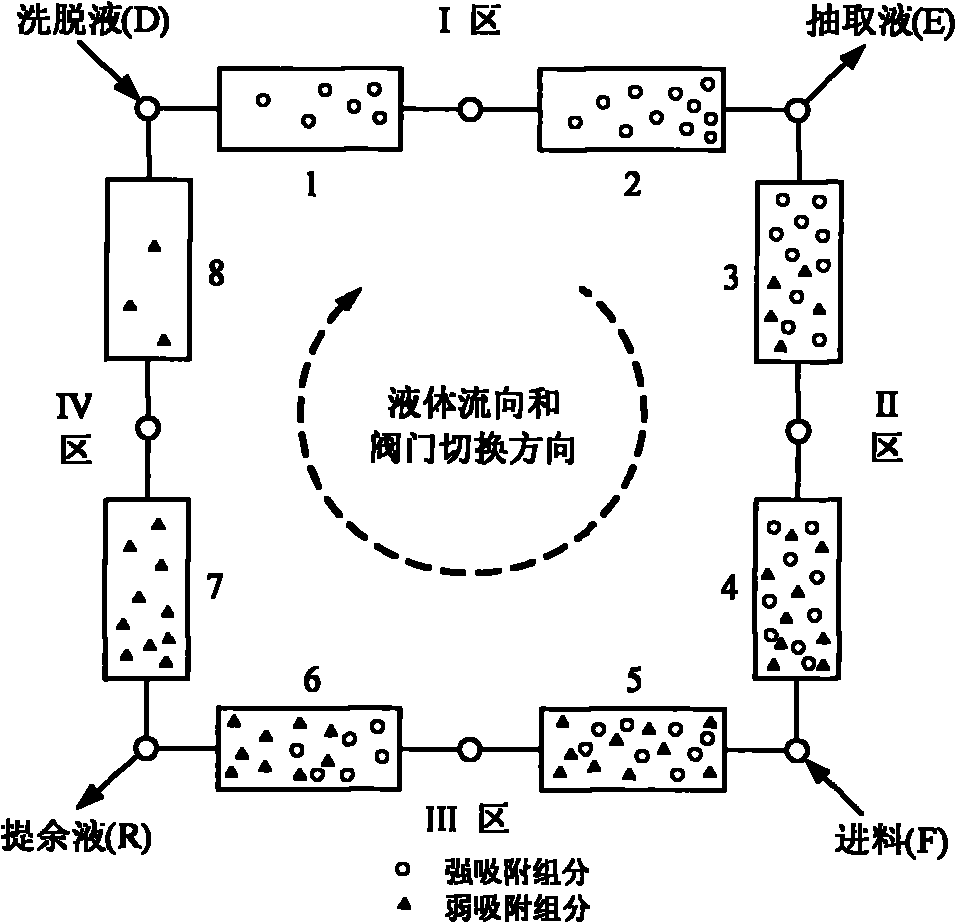

[0083] Example Taking the simulated moving bed extraction process of the weak enantiomer of a certain chiral compound as an example, the present invention is used to find the best operating point of the simulated moving bed device, so that the production process can obtain high raffinate purity and raffinate productivity. The specific implementation steps are as follows:

[0084] (1) The bed parameters of the simulated moving bed are measured by the measurement method described in the embodiment or directly obtained from the instruction manual of the equipment supplier.

[0085] (2) The adsorption isotherm adopts the bi-Langmuir isotherm form, and the isotherm parameters are determined by a combination of static method and flow method.

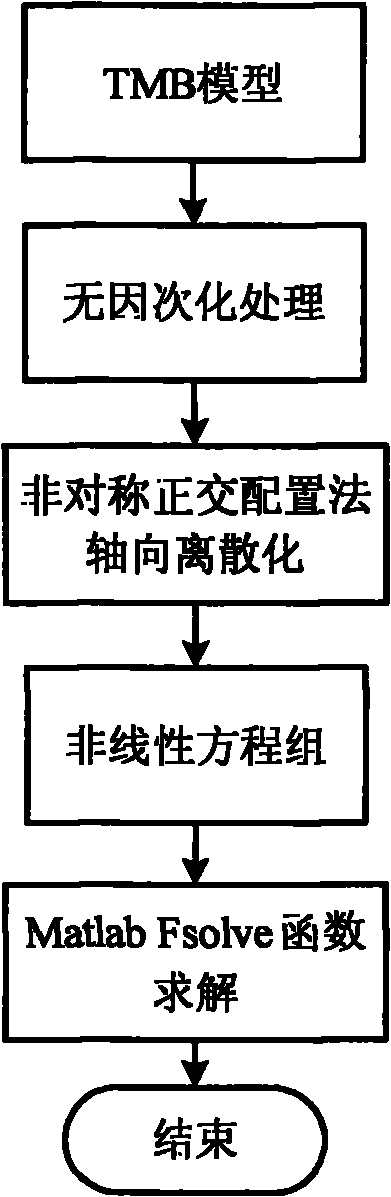

[0086] (3) This embodiment is based on the TMB model of the general rate theory as the basis of the mathematical model, and the specific form of the model equation is shown in the implementation steps of the solution of the present invention. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com