Ammonia-plaster mode desulphurization system

A technology of desulfurization system and gypsum method, applied in separation methods, chemical instruments and methods, calcium/strontium/barium sulfate, etc., can solve the problem of insufficient use of desulfurization absorption liquid, easy scaling and blockage of equipment, and large investment of ammonium sulfate method and other problems, to achieve the effect of stable and reliable continuous operation, small footprint and simple maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

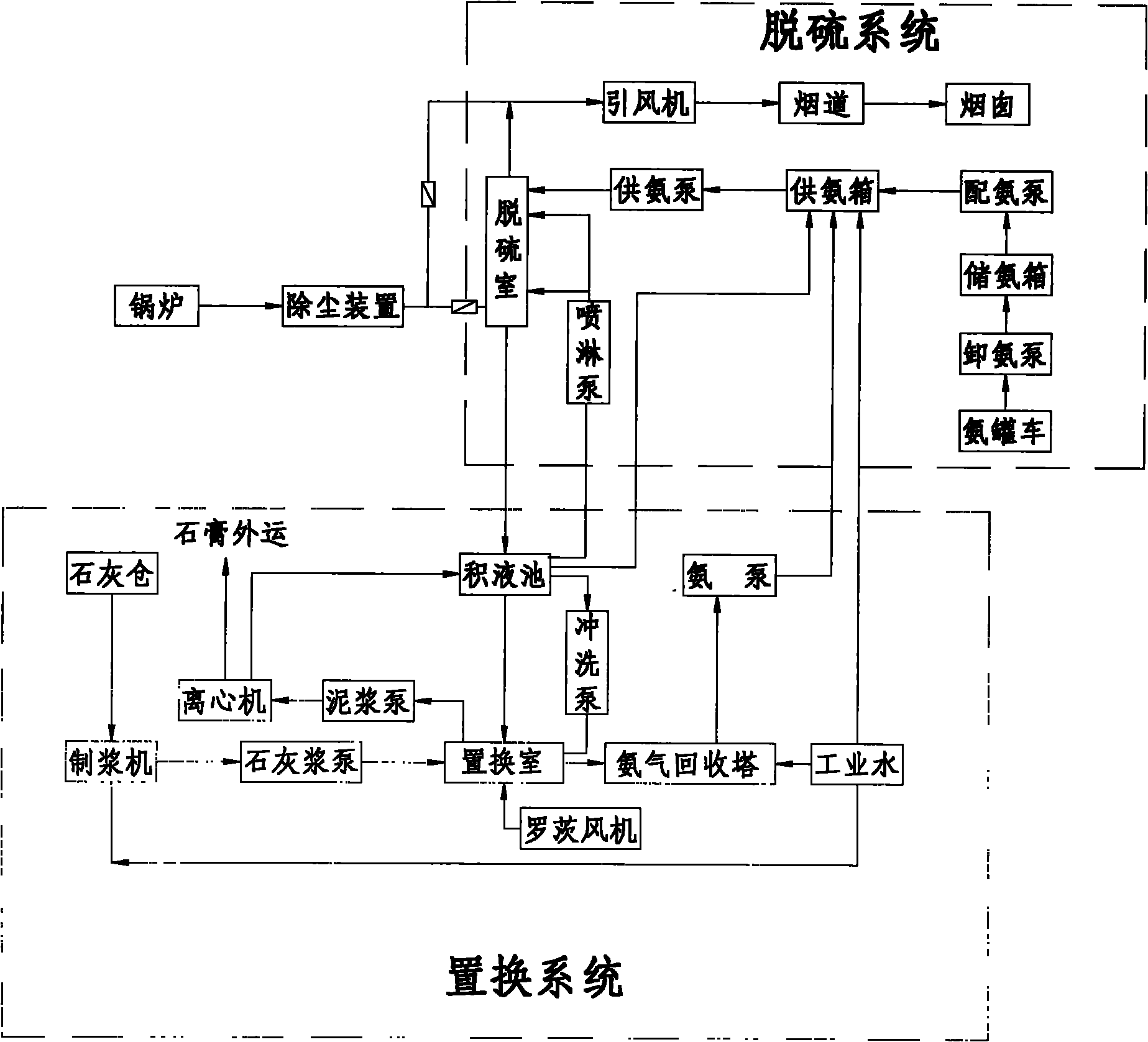

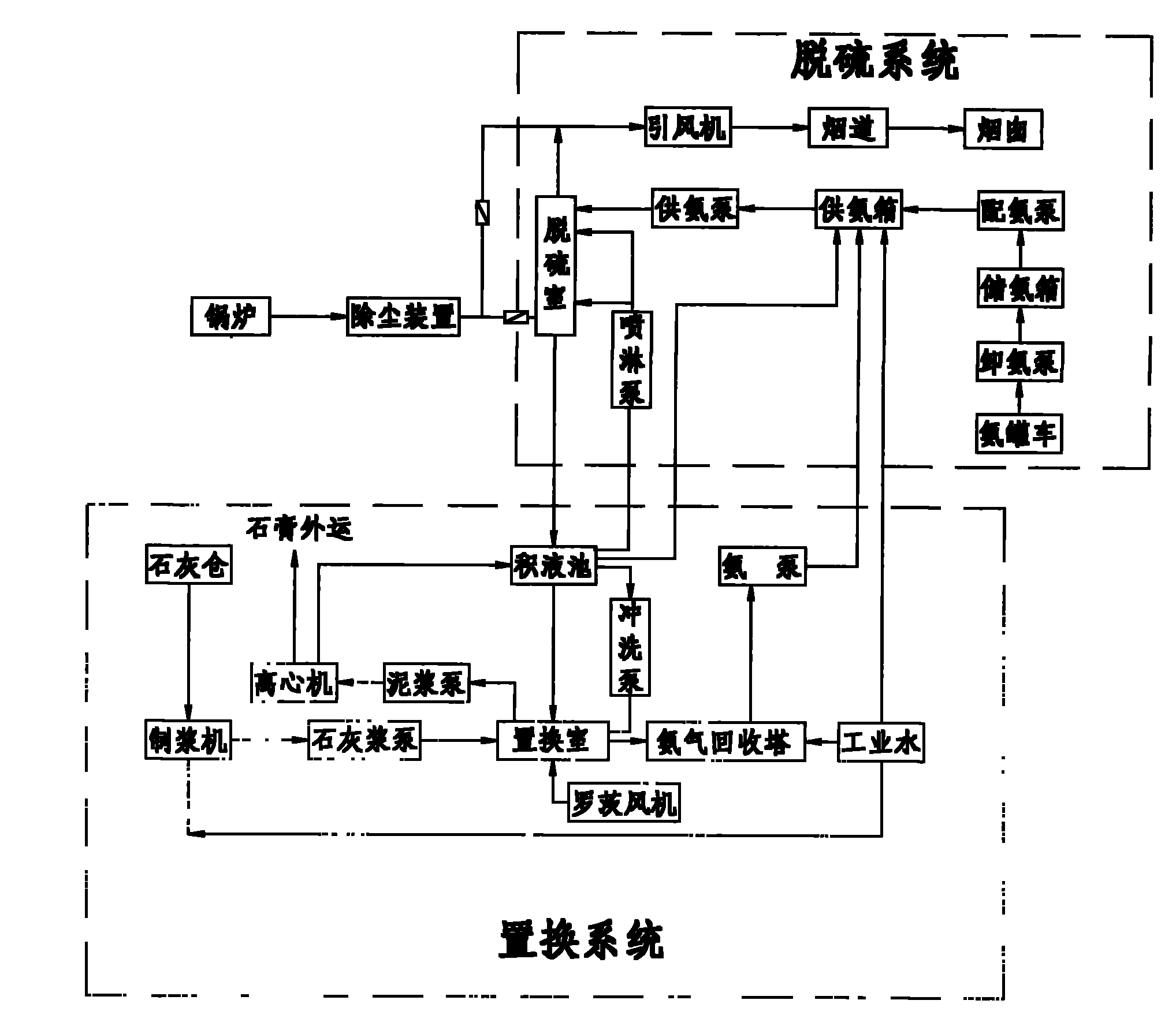

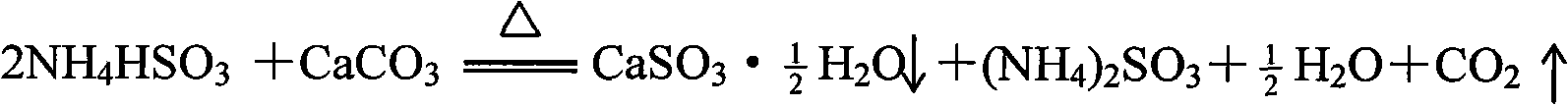

[0017] The ammonia-gypsum method is to use liquid ammonia, ammonia water or ammonium bicarbonate as a desulfurizer to absorb SO2 in the flue gas, and then use quicklime (calcium oxide) or calcium hydroxide and the desulfurized product ammonium sulfite solution in a displacement tank. The displacement reaction produces calcium sulfite and ammonia gas. The calcium sulfite solution is oxidized with the oxygen sent by the oxidation fan to produce calcium sulfate, which is sold after being filtered and dried. The displaced ammonia gas is sent to the ammonia gas recovery tower through the pipeline, and the ammonia gas is absorbed by the process water to produce ammonia water, which is recycled as a desulfurizer again.

[0018] Such as figure 1 As shown, the present invention includes a desulfurization system and a replacement system.

[0019] The desulfurization system includes ammonia tank truck, ammonia unloading pump, ammonia storage tank, ammonia distribution pump, ammonia sup...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com