Method and device for biochemically recharging and restoring polluted soils in chromium slag yard

A technology for polluted soil and chromium slag storage yard, applied in the field of environmental engineering, can solve the problems of unreported engineering remediation of chromium-contaminated soil, harsh soil conditions by electric remediation method, secondary soil pollution, etc. The effect of restoring and improving soil physicochemical properties and easily controllable conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

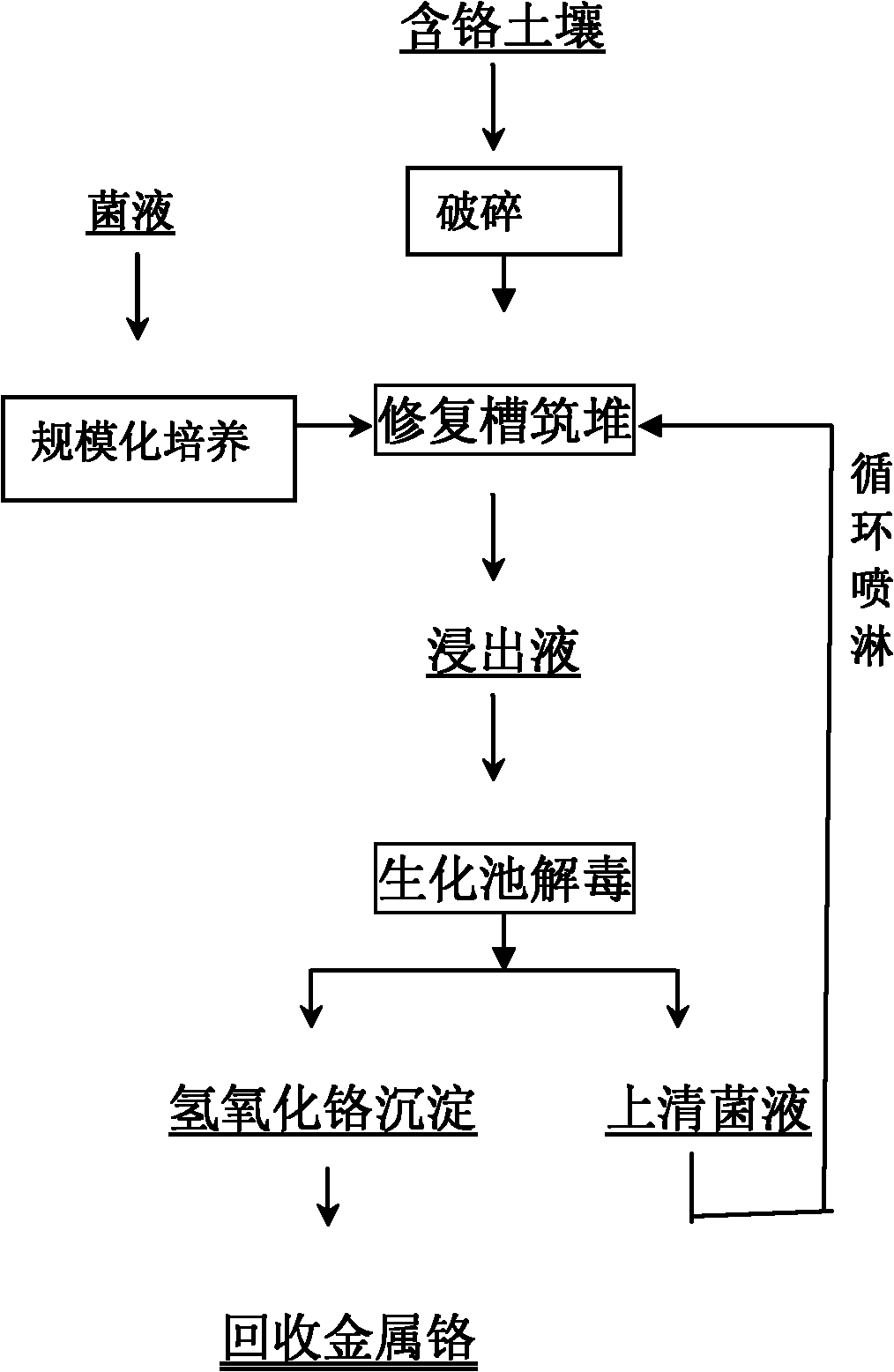

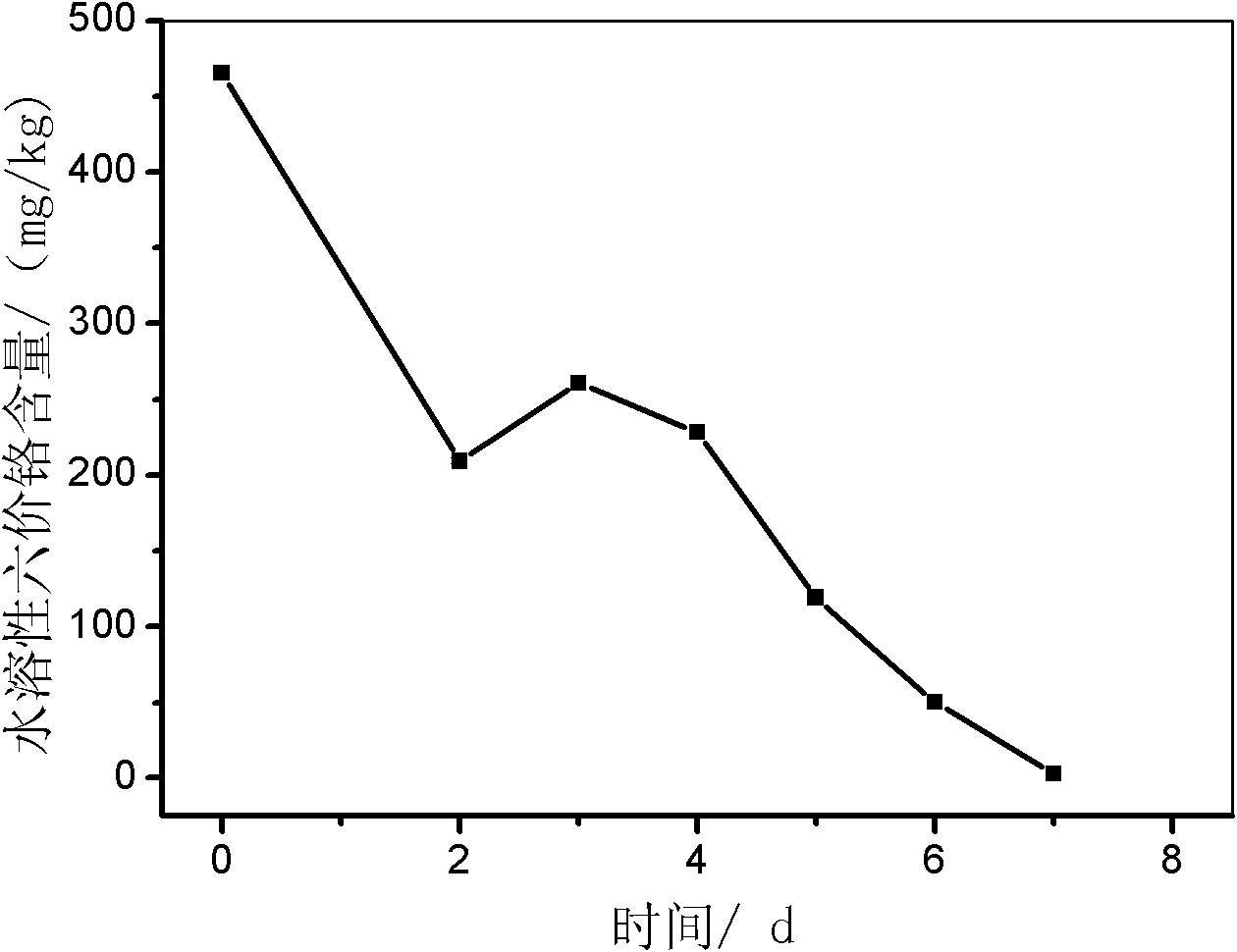

[0037] Example 1: Soil remediation of chromium slag yard of Minmetals (Hunan) Ferroalloy Co., Ltd.

[0038] The soil under the chromium slag yard of Minmetals (Hunan) Ferroalloy Co., Ltd. is crushed into soil clods smaller than 2cm through a jaw crusher with a 2cm rolling screen, and transferred to a soil tank of 5.0×4.0×1.0m (Leave an opening with a diameter of 15cm in the lower part of the soil tank), and build a 25-ton (5.0×4.0×0.8m) mound. The flow rate is 1.5m 3 / h alkali-resistant pump pumps the cultivated Pannonibacter phragmitetusBB bacteria solution to spray the soil, and the spray intensity is 0.011m 3 / h.m 2 , collect the leachate from the opening of the soil tank in a volume of 0.5m 3 Intermediate pool of cubic meters with a flow rate of 1.5m 3 / h alkali-resistant pump pumps the leachate from the intermediate pool to a volume of 4m 3 Biochemical reaction is carried out in the biochemical pool, and the bacterial solution of the biochemical pool is extracted to ...

Embodiment 2

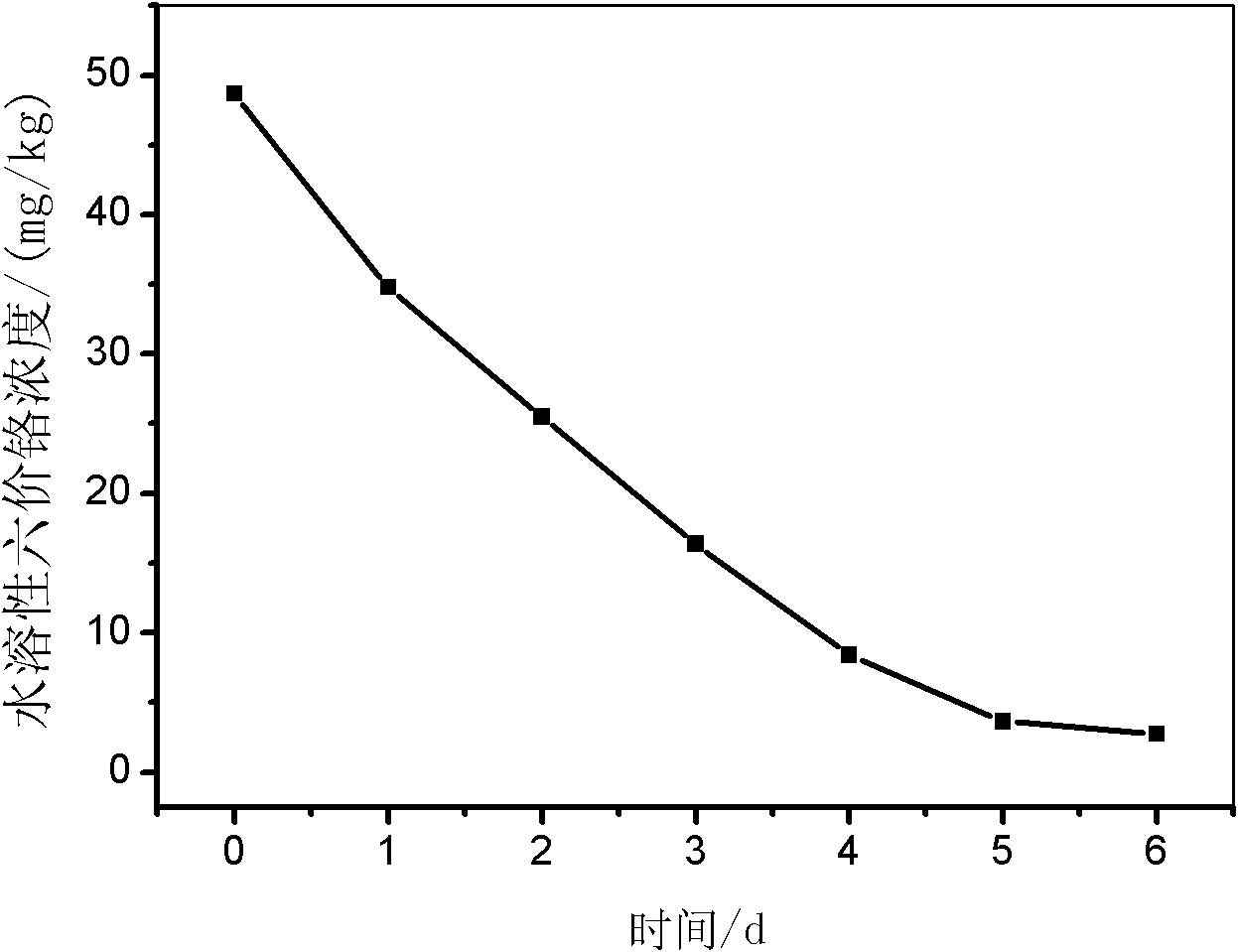

[0042] Example 2: Remediation of Chromium Slag Contaminated Soil in Shuangfeng County

[0043] For the chromium slag-contaminated soil in Shuangfeng County, the soil particles were broken into clods smaller than 2cm by using a jaw crusher with a 2cm rolling sieve, and transferred to a soil trough of 5.0×4.0×1.0m (the bottom of the trough left a diameter of 15cm opening), build a 25-ton (5.0×4.0×0.8m) mound. The flow rate is 1.5m 3 The alkali-resistant pump pumped out the cultured Pannonibacter phragmitetus BB to spray the soil with an alkali-resistant pump at a spray intensity of 0.011m 3 / h.m 2 , collect the leachate from the opening of the soil tank in a volume of 0.5m 3 Intermediate pool of cubic meters with a flow rate of 1.5m 3 / h alkali-resistant pump pumps the leachate from the intermediate pool to a volume of 4m 3 Biochemical reaction is carried out in the biochemical pool, and the bacterial solution of the biochemical pool is extracted to circulate and spray the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com