Method for removing ammonia nitrogen from artificial leather manufacturing waste water

A technology for tannery wastewater and wastewater, applied in the field of environmental engineering, can solve the problems of ecological environment pollution, ammonia nitrogen exceeding the standard, etc., and achieve the effects of low operating cost, removal of ammonia nitrogen, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

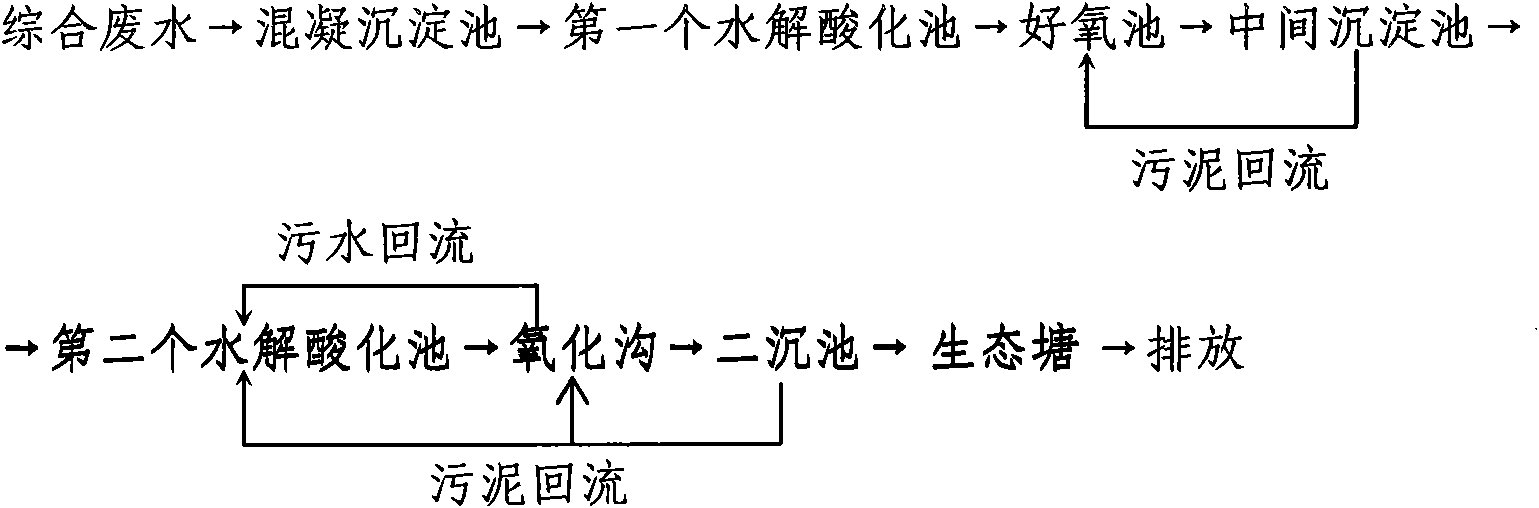

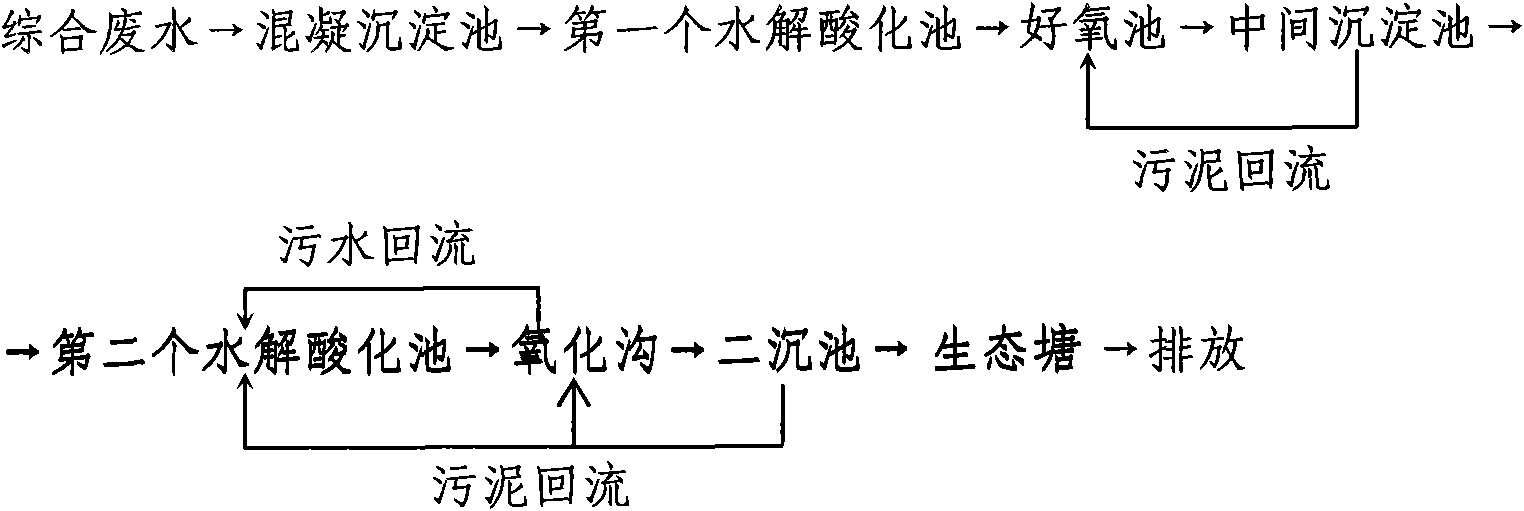

Method used

Image

Examples

Embodiment 1

[0018] (1) Tannery wastewater, the influent water volume is 3353m 3 / d, the water quality is as follows: pH is 6.78, COD Cr 518mg / L, BOD 108mg / L, NH 3 -N is 105mg / L, SS is 338mg / L, polyaluminum chloride is added for coagulation and sedimentation pretreatment, the dosage of polyaluminum chloride is 1.5g / L, and the effluent quality is as follows: pH is 7.87, COD Cr 316mg / L, BOD 96mg / L, NH 3 -N is 74mg / L, SS is 62mg / L,

[0019] (2) Discharge the pretreated wastewater into the first hydrolytic acidification tank, the hydraulic retention time is 12h, use the microorganisms in the wastewater to hydrolyze and acidify, decompose the macromolecular organic matter into small molecular organic matter, and remove the waste water through the cell synthesis of microorganisms part of the ammonia nitrogen. After treatment, the effluent water quality is as follows: pH is 7.38, COD Cr 290mg / L, BOD 111mg / L, NH 3 -N is 35mg / L, SS is 47mg / L;

[0020] (3) Discharge the wastewater after hydro...

Embodiment 2

[0027] (1) Tannery wastewater, the influent water volume is 3187m 3 / d, the water quality is as follows: pH is 6.82, COD Cr 650mg / L, BOD 122mg / L, NH 3 -N is 171mg / L, SS is 362mg / L, polyaluminum chloride is added for coagulation and sedimentation pretreatment, the dosage of polyaluminium chloride is 1.5g / L, and the effluent water quality is as follows: pH is 7.65, COD Cr 448mg / L, BOD 115mg / L, NH 3 -N is 90mg / L, SS is 60mg / L,

[0028] (2) Discharge the pretreated wastewater into the first hydrolytic acidification tank, with a hydraulic retention time of 12 hours, use the microorganisms in the wastewater to hydrolyze and acidify, decompose the macromolecular organic matter into small molecular organic matter, and remove the waste water through the cell synthesis of microorganisms part of the ammonia nitrogen. After treatment, the effluent water quality is as follows: pH is 7.28, COD Cr 403mg / L, BOD 144mg / L, NH 3 -N is 58mg / L, SS is 53mg / L;

[0029] (3) Discharge the wastew...

Embodiment 3

[0036] (1) Tannery wastewater 1, the influent water volume is 3384m 3 / d, the water quality is as follows: pH is 6.53, COD Cr 545mg / L, BOD 98mg / L, NH 3 -N is 1205mg / L, SS is 343mg / L, polyaluminum chloride is added for coagulation and sedimentation pretreatment, the dosage of polyaluminium chloride is 1.5g / L, and the effluent quality is as follows: pH is 7.68, COD Cr 336mg / L, BOD 82mg / L, NH 3 -N is 88mg / L, SS is 56mg / L,

[0037] (2) Discharge the pretreated wastewater into the first hydrolytic acidification tank, the hydraulic retention time is 12h, use the microorganisms in the wastewater to hydrolyze and acidify, decompose the macromolecular organic matter into small molecular organic matter, and remove the waste water through the cell synthesis of microorganisms part of the ammonia nitrogen. After treatment, the effluent water quality is as follows: pH is 7.42, COD Cr 298mg / L, BOD 88mg / L, NH 3 -N is 63mg / L, SS is 44mg / L;

[0038] (3) Discharge the wastewater after hyd...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com