Integral reactor of dielectric barrier discharge coupling catalyst for removing NOx in diesel engine

A dielectric barrier discharge and catalyst technology, which is applied in the direction of machines/engines, mechanical equipment, engine components, etc., can solve the problems of catalyst sulfur poisoning, achieve the effects of solving sulfur poisoning, long residence time, and improving selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

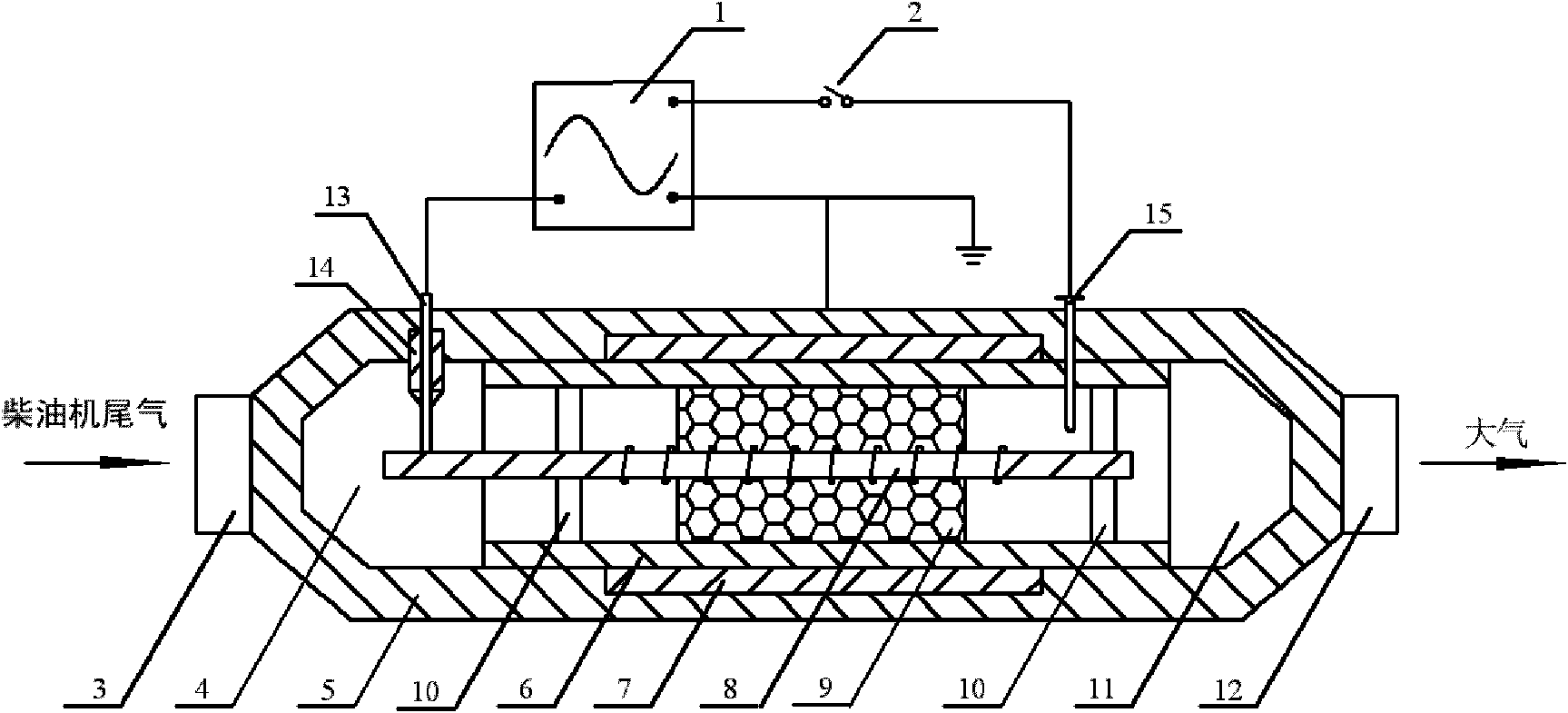

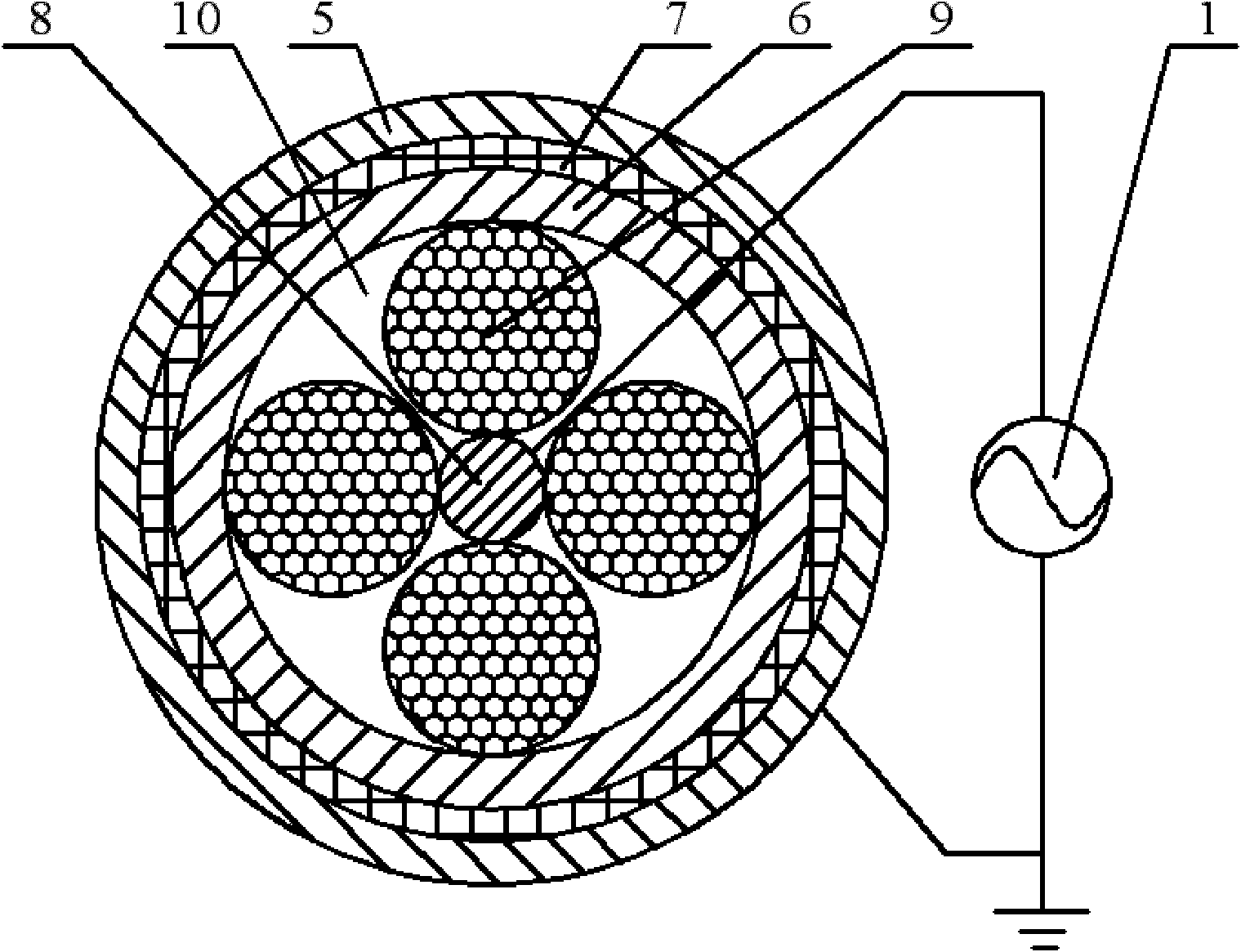

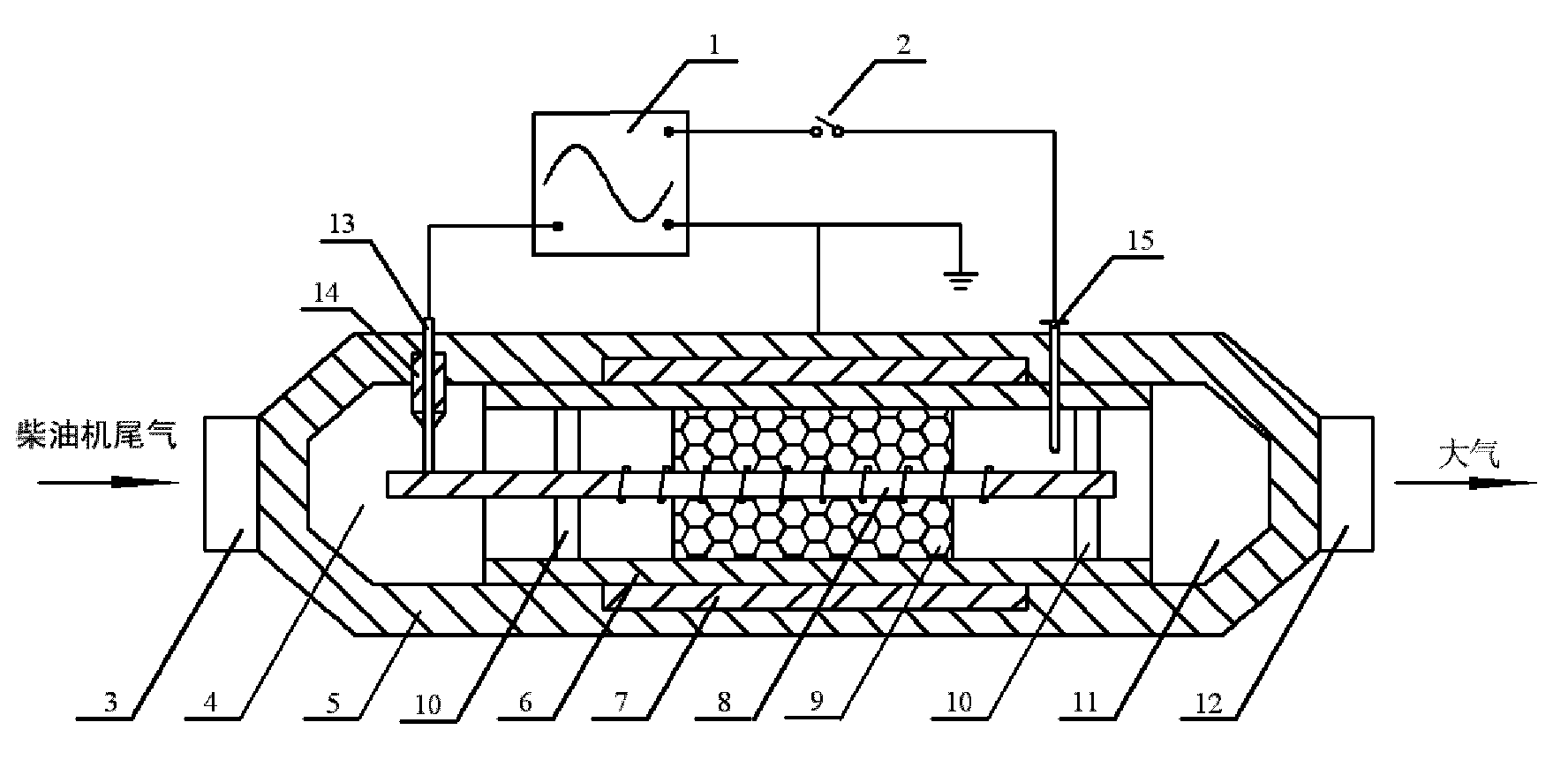

[0029] The specific implementation of the present invention will be further described below in conjunction with the accompanying drawings.

[0030] Such as figure 1 , figure 2 As shown, the present invention includes: a high-voltage high-frequency pulse power supply 1, a power control switch 2, an air intake pipe 3, an air intake air guide cover 4, an insulating jacket layer 5, a corundum tube 6, a stainless steel mesh low-voltage electrode 7, and a stainless steel mandrel high-voltage electrode 8. SCR catalyst 9, two floating centering porous plates 10, air outlet air guide cover 11, air outlet pipe 12, high voltage discharge positive rod 13, polytetrafluoroethylene insulating column 14, temperature sensor 15; using Al 2 o 3 Corundum tube 6 is used as a dielectric material, its inner diameter is 20mm, outer diameter is 25mm, and length is 276mm; the middle section is processed into a spiral stainless steel mandrel high-voltage electrode 8 placed at the axis of corundum tub...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com