Manufacturing method of light emitting diode chip

A technology of light-emitting diodes and manufacturing methods, which is applied in the direction of electrical components, circuits, semiconductor devices, etc., can solve the problems affecting the reliability of devices, such as less than 10%, and achieve the effects of improving light extraction efficiency, increasing side wall light output, and improving brightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

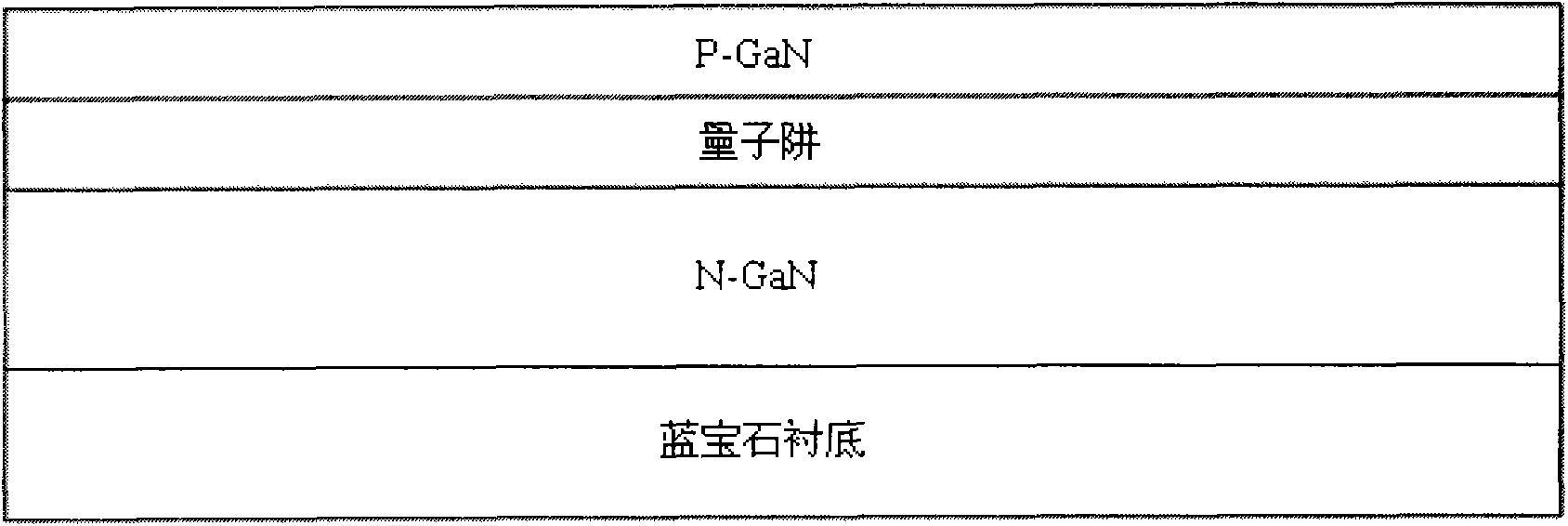

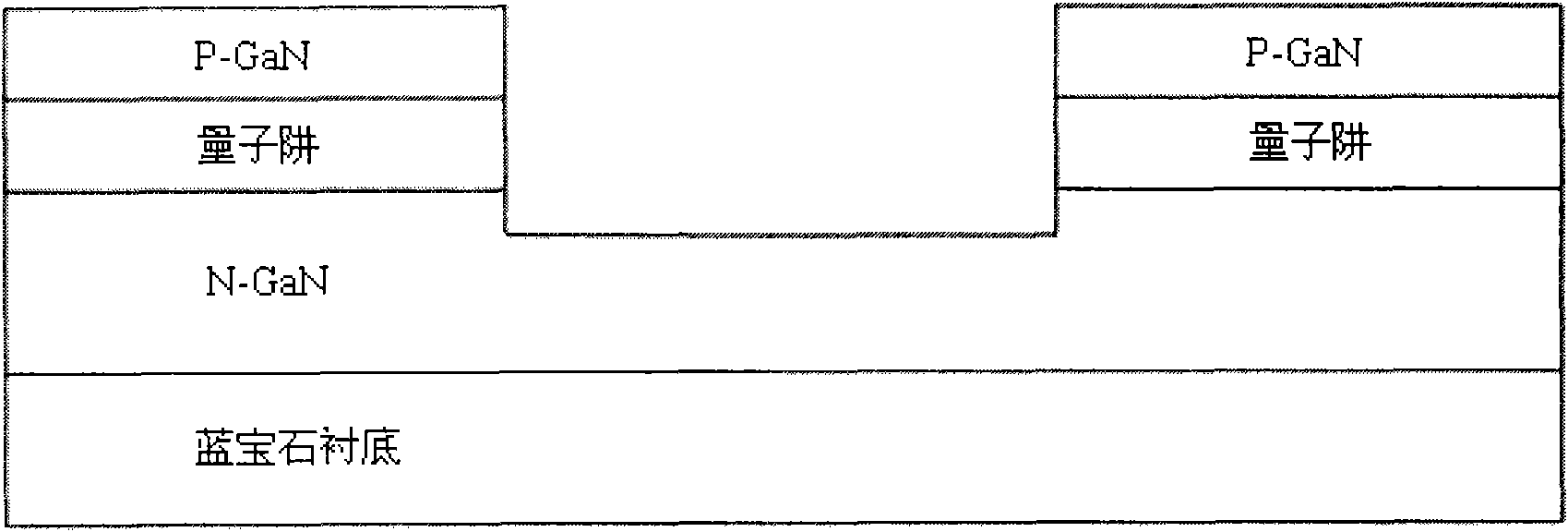

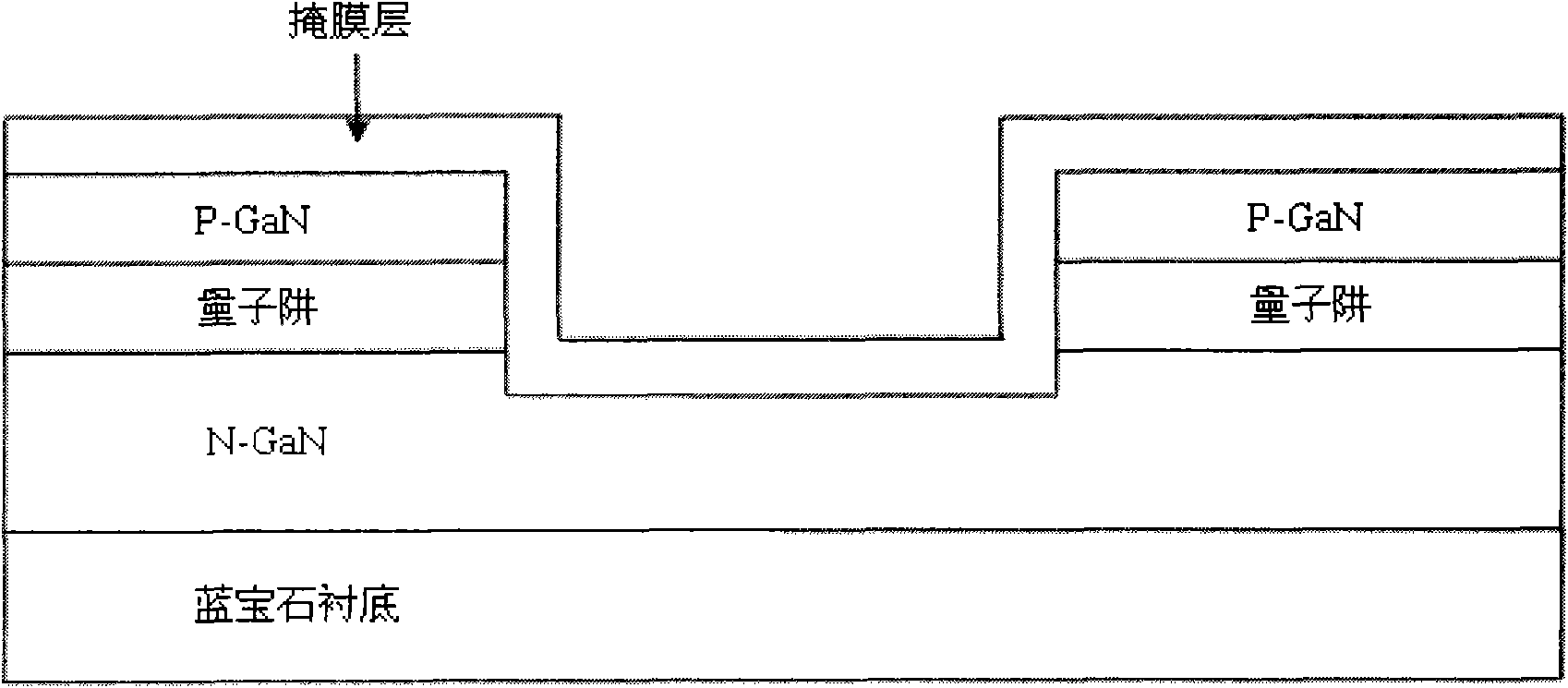

[0025] Please see Figure 1A to Figure 1E , take 10 * 23mil chip as example, specifically illustrate the implementation process of the inventive method:

[0026] Step 1, growing a semiconductor epitaxial layer on a sapphire substrate, the layer at least including an N-type GaN layer, an active layer on the N-type GaN layer, and a P-type GaN layer on the active layer ,like Figure 1A shown. Among them, when preparing the semiconductor layer, techniques such as metal organic chemical vapor deposition (MOCVD), molecular beam epitaxy (MBE), and hydride vapor phase epitaxy (HVPE) can be used. In this embodiment, preferably, an N-type GaN layer, an active layer, and a P-type GaN layer are sequentially grown on a sapphire substrate by metal-organic chemical vapor deposition technology. The active layer is usually a quantum well layer.

[0027] Step 2: Etching the structure obtained in Step 1 by using ICP Etching (Inductively Coupled Plasma Etching) or RIE (Reactive Ion Etching) t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com