Coalescence material and preparation method

A technology of coalescing materials and formulations, which is applied in the direction of separation methods, liquid separation, grease/oily substances/floating matter removal devices, etc., can solve the problems of low oil removal efficiency and poor coalescence effect of crude oil, and improve oil removal efficiency , Improving the balance of lipophilicity and hydrophilicity, and the effect of parameter optimization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0019] Material formula (master batch):

[0020] Polypropylene: 71.5%

[0021] Polyvinylidene fluoride: 4%

[0022] Nano calcium carbonate: 3%

[0023] Glass fiber: 20%

[0024] Antioxidant (1010): 1.5% addition

[0025] The packing structure is a flat plate, which is prepared by extrusion calendering process at 180℃

example 2

[0027] Material formula (master batch):

[0028] Polypropylene: 77.5%

[0029] Polyvinylidene fluoride: 6%

[0030] Nano calcium carbonate: 5%

[0031] Glass fiber: 10%

[0032] Antioxidant (1010): 1.5% addition

[0033] The packing structure is corrugated board, which is prepared by extrusion calendering process at 180℃

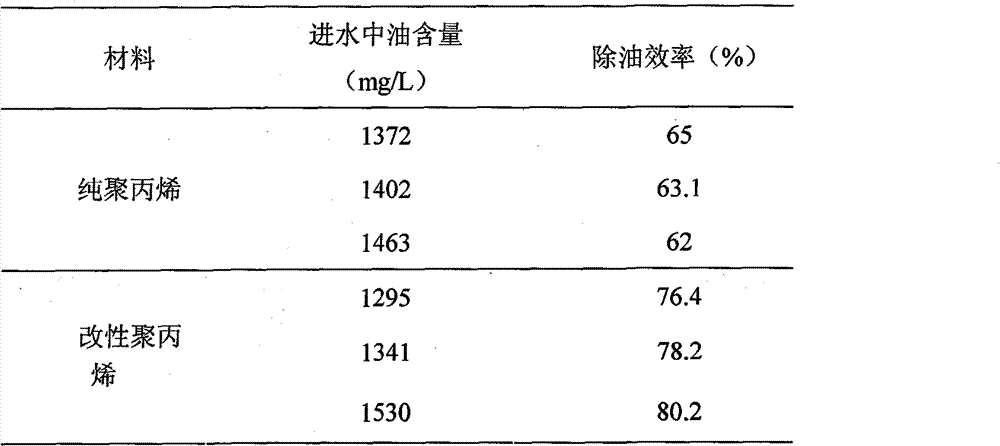

[0034] Through the application of flat plates, corrugated plates and egg trays made of polypropylene modified coalescing materials to the application of coalescing oil from oily sewage at the Tuoyi Joint Station of Shengli Oil Production Plant of Shengli Oilfield, significant effects have been seen.

[0035] The experiment on coalescing and degreasing of oily sewage in the oil field was carried out at the Tuo Yi Joint Station of Shengli Oil Production Plant. The produced water of Tuoyi Station contains more polyacrylamide, so oil-water separation is more difficult. The oil-water separation device for coalescence test is 200cm long, 40cm wide, 70cm high, and its effecti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com