Preparation method of single-green up-conversion fluorescent marking material

A fluorescent labeling and green technology, applied in the field of preparation of fluorescent labeling materials, can solve the problems of low detection sensitivity, complicated preparation process, poor chemical stability, etc., and achieve the effects of low reaction temperature, good monochromaticity, and short reaction time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

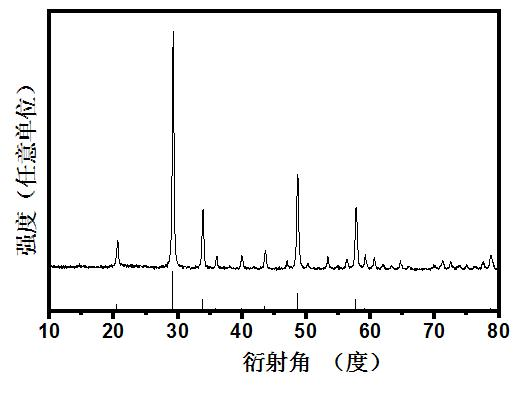

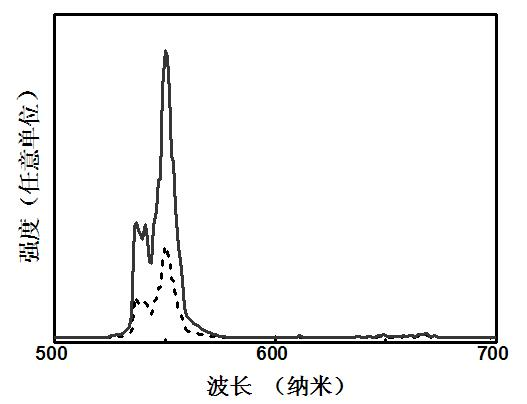

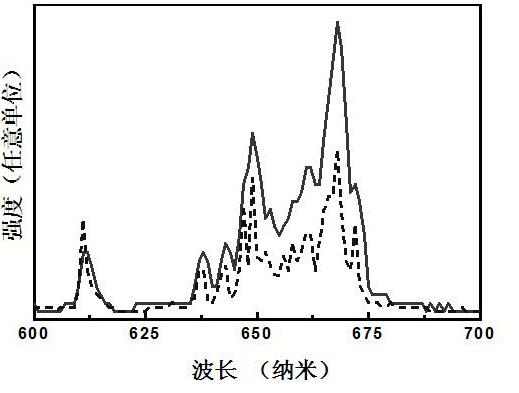

[0008] Specific embodiment one: the preparation method of the single green up-conversion fluorescent labeling material in the present embodiment is as follows: one, the Y 2 o 3 , Yb 2 o 3 、Ho 2 o 3 and Eu 2 o 3 Dissolve in concentrated nitric acid, add deionized water, then add LiNO 3 solution, stirred evenly at room temperature to obtain a transparent solution, Y in the transparent solution 3+ Ions and Yb 3+ The molar ratio of ions is 1:0~10, Y 3+ Ions and Ho 3+ The molar ratio of ions is 1:0.1~0.5, Y 3+ Ions and Eu 3+ The molar ratio of ions is 1:0~2, Y 3+ Ions and Li + The molar ratio of ions is 1:0~15; 2. According to the molar ratio of cations and citric acid in the transparent solution is 1:3~5, add citric acid to the transparent solution and stir until it is completely dissolved, then add ammonia water to adjust The pH value is 5~7; 3. Dry the solution obtained in step 3 at 100~150°C for 12~20 hours to obtain xerogel; 4. Calcinate the xerogel at 600~1000°C...

specific Embodiment approach 2

[0011] Specific embodiment two: the difference between this embodiment and specific embodiment one is that Y in step one transparent solution 3+ Ions and Yb 3+ The molar ratio of ions is 1:1~9, Y 3+ Ions and Ho 3+ The molar ratio of ions is 1:0.2~0.4, Y 3+ Ions and Eu 3+ The molar ratio of ions is 1:1~1.5, Y 3+ Ions and Li + The molar ratio of ions is 1:1~14. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0012] Specific embodiment three: the difference between this embodiment and specific embodiment one is that Y in step one transparent solution 3+ Ions and Yb 3+ The molar ratio of ions is 1:8, Y 3+ Ions and Ho 3+ The molar ratio of ions is 1:0.3, Y 3+ Ions and Eu 3+ The molar ratio of ions is 1:1.5, Y 3+ Ions and Li + The molar ratio of ions is 1:10. Others are the same as in the first embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com