Plasma treatment apparatus

A plasma and processing device technology, applied in the field of plasma processing devices, can solve problems such as easy rise of surface potential, inability to achieve stabilization, and reduced processing efficiency, so as to suppress short circuit or abnormal discharge, improve power consumption efficiency, and stabilize plasma The effect of body treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

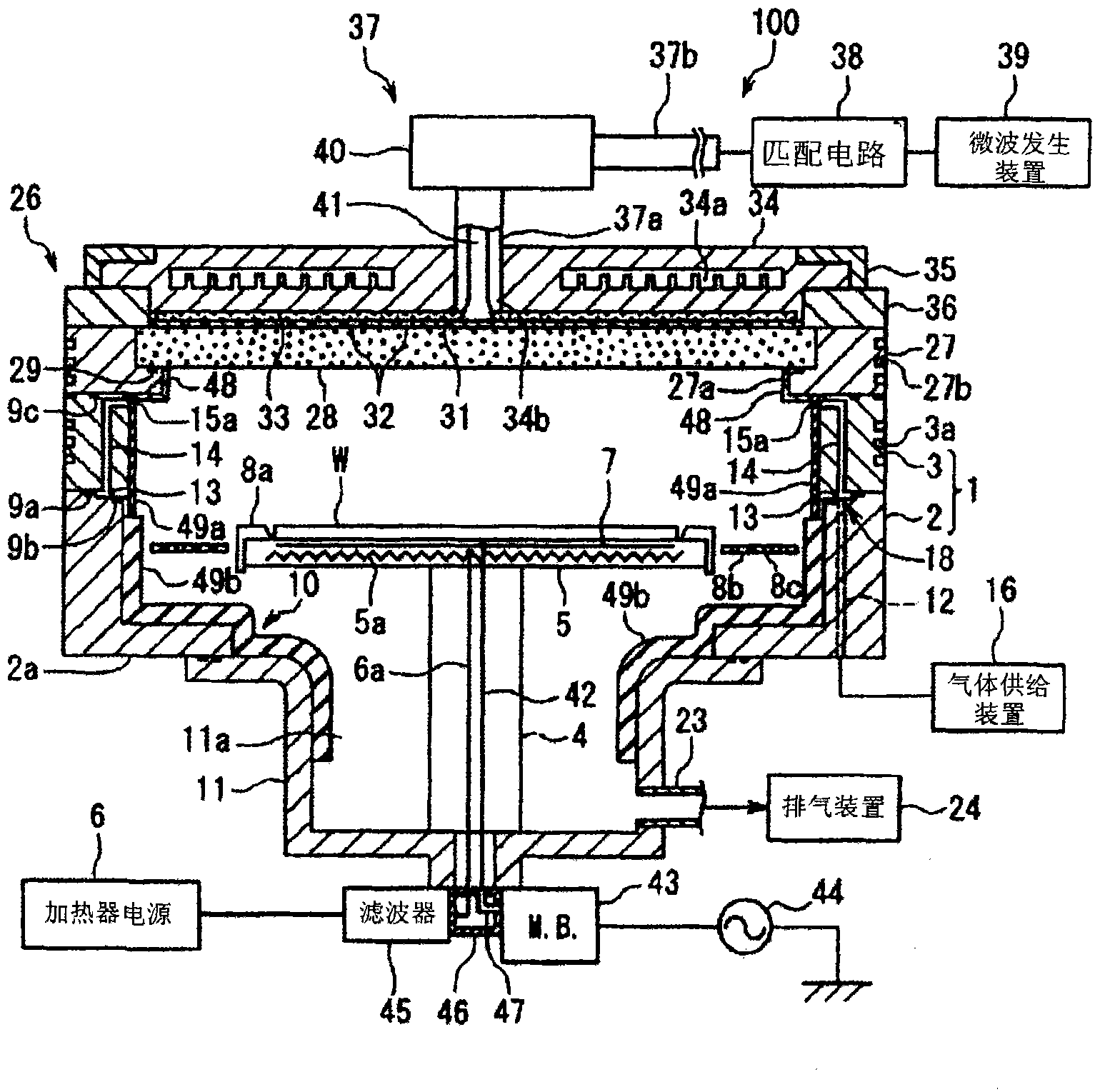

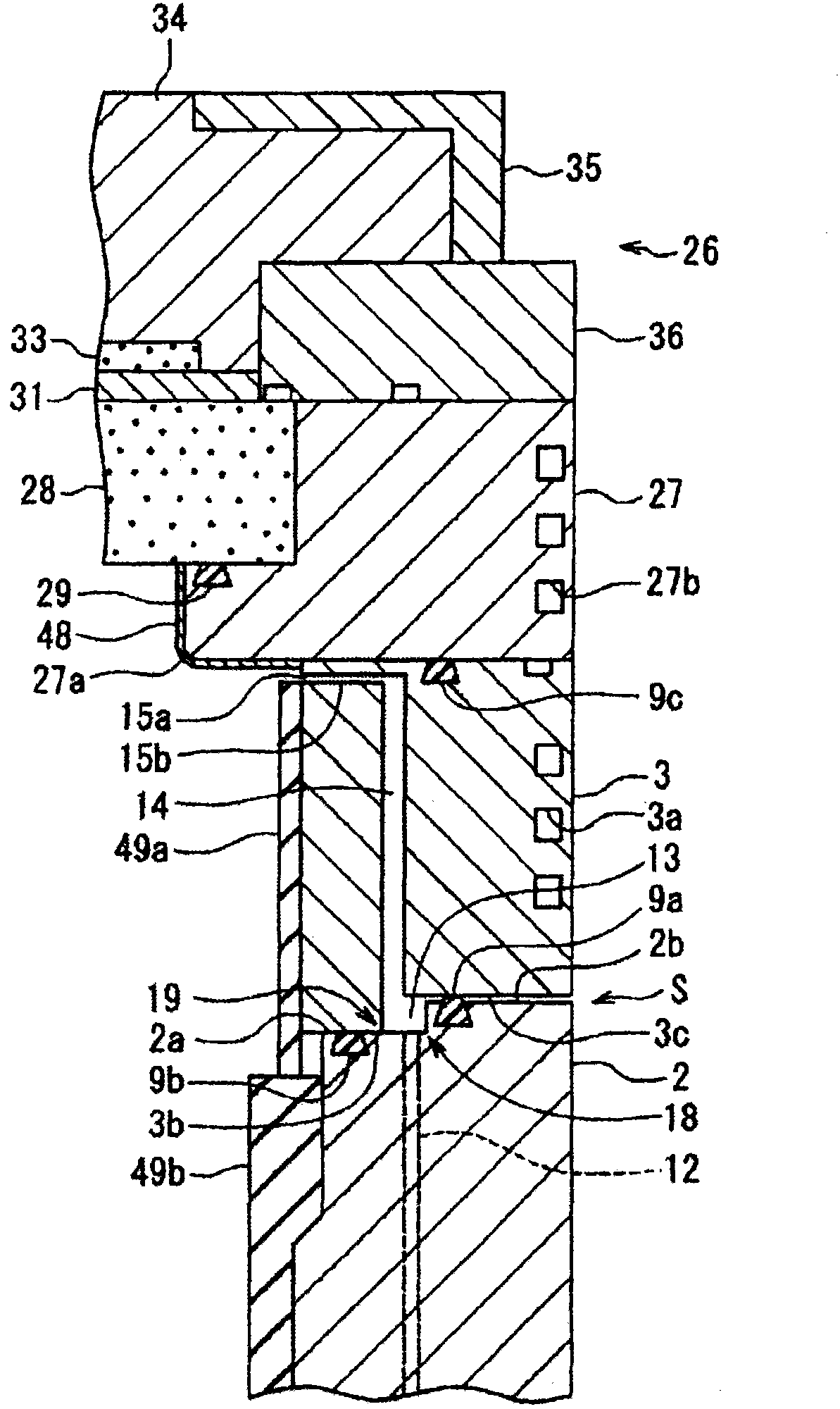

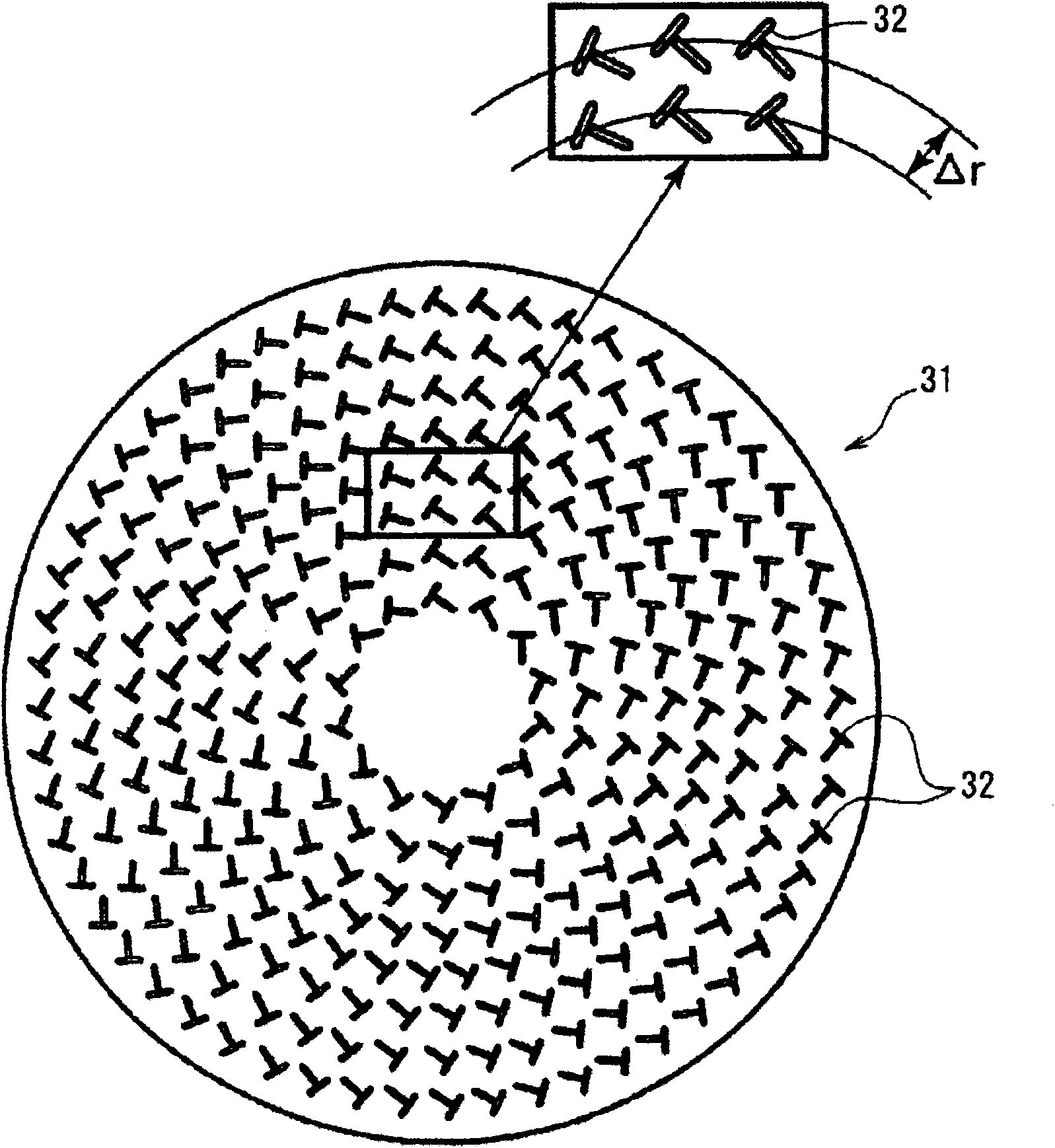

[0024] Embodiments of the present invention will be described in detail below with reference to the drawings. figure 1 It is a cross-sectional view schematically showing a schematic structure of a plasma oxidation processing apparatus 100 which is an embodiment of the plasma processing apparatus of the present invention. also, figure 2 is enlarged figure 1 Cross-sectional view of the main part. also, image 3 yes means figure 1 A plan view of the planar antenna of the plasma oxidation treatment apparatus 100.

[0025] The plasma oxidation processing apparatus 100 is configured to directly introduce microwaves into the processing container through a planar antenna having a plurality of slot-like holes, especially RLSA (Radial Line Slot Antenna), RLSA microwave plasma processing device that generates microwave-excited plasma with high density and low electron temperature. In the plasma oxidation treatment device 100, it is possible to use 10 ~5×10 12 / cm 3 The plasma d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com