Biological fermentation process for improving protein content of cottonseed meal and detoxicating cottonseed meal

A biological fermentation method and protein content technology, applied in the field of biological fermentation method, can solve the problems of reducing protein quality and extraction rate, low protein extraction rate, affecting protein extraction, etc., to reduce feces odor and harmful gas emissions, and improve feed quality. Protein quality, effect of eliminating bitter taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

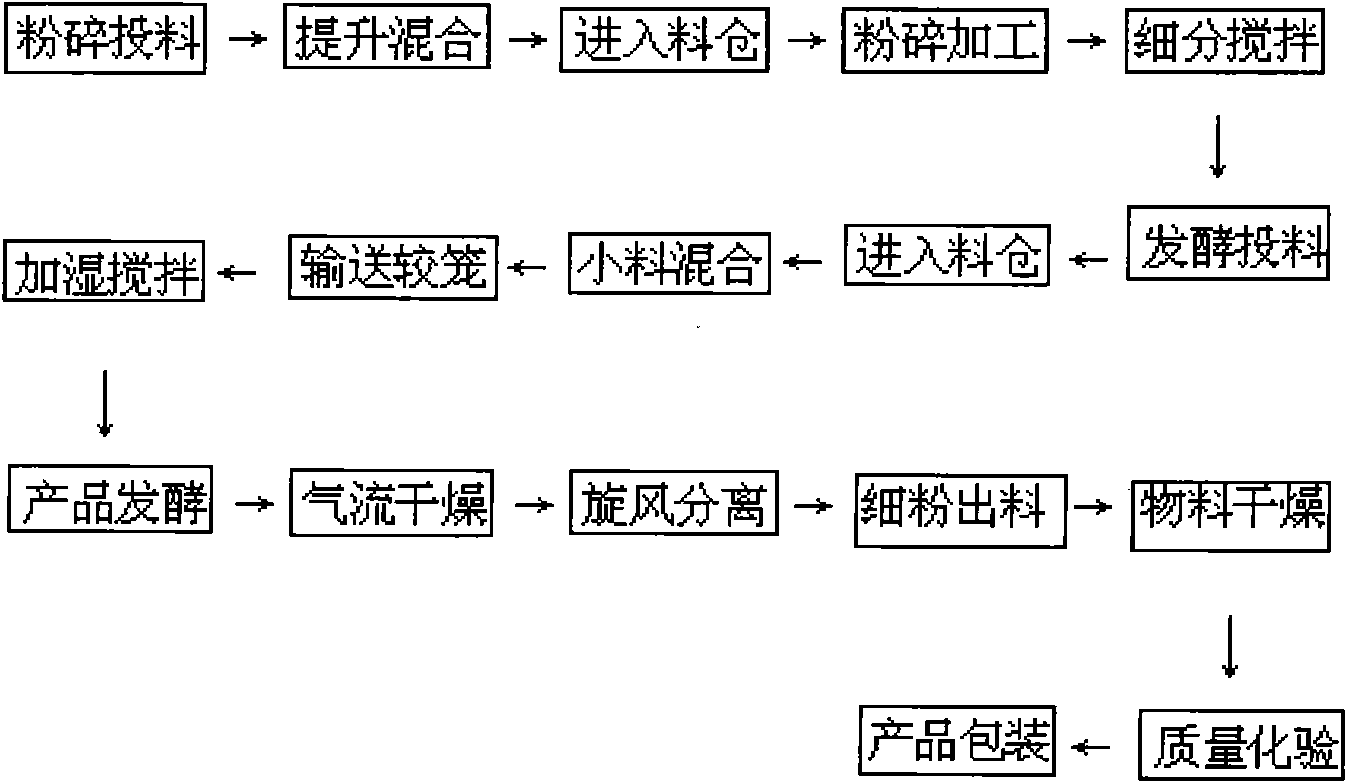

Image

Examples

Embodiment Construction

[0016] The invention adopts microbial fermentation technology to process cotton meal, breaks plant cell wall, and removes free gossypol contained in cotton meal and other anti-nutritional factors, such as cyclopropene fatty acid (CPFA), phytic acid, tannin, non-starch polysaccharide and Modification, transfer, recombination, purification and other detoxification treatment of non-polysaccharides, etc., to improve the digestion and utilization rate of plant protein and the quality of raw protein; degrade the large molecular weight protein in cotton meal that is not easy to be absorbed by animals through biological enzymatic hydrolysis into active small peptides , retain probiotics, digestive enzymes, lactic acid and various bioactive factors in the product.

[0017] The invention adopts the method of microbial fermentation to degrade and remove toxic substances such as free gossypol in cottonseed meal, and at the same time decomposes large molecular weight protein in cottonseed m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com