Manufacturing process for accurate connection of large-scale steel structure members and flanges

A technology of steel structure parts and manufacturing process, which is applied in the field of manufacturing process of precise flange connection of large steel structure parts, can solve the problems of difficult construction, non-fit flange contact surfaces, and non-vertical connection flanges, and saves production. Cost and time, guarantee technical specification requirements, guarantee the effect of welding quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Below in conjunction with preferred embodiment, the specific implementation mode provided according to the present invention is described in detail as follows:

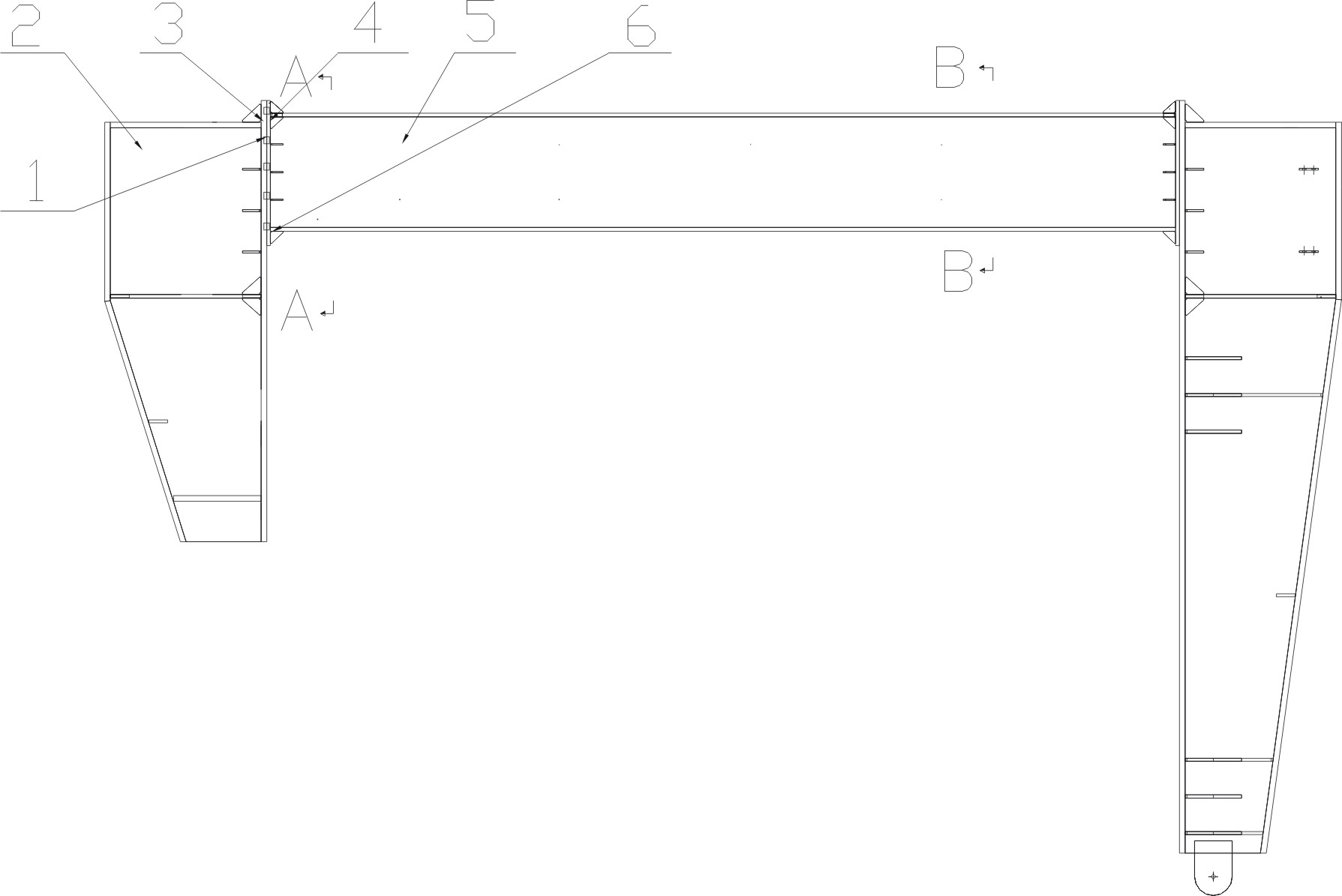

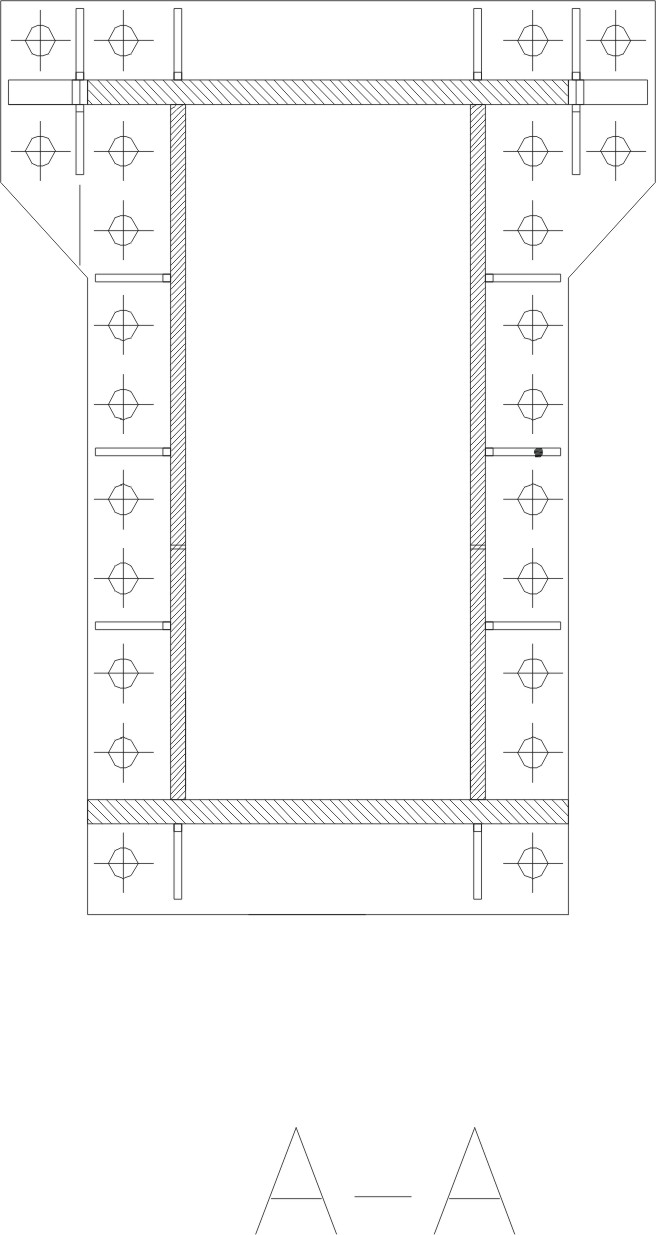

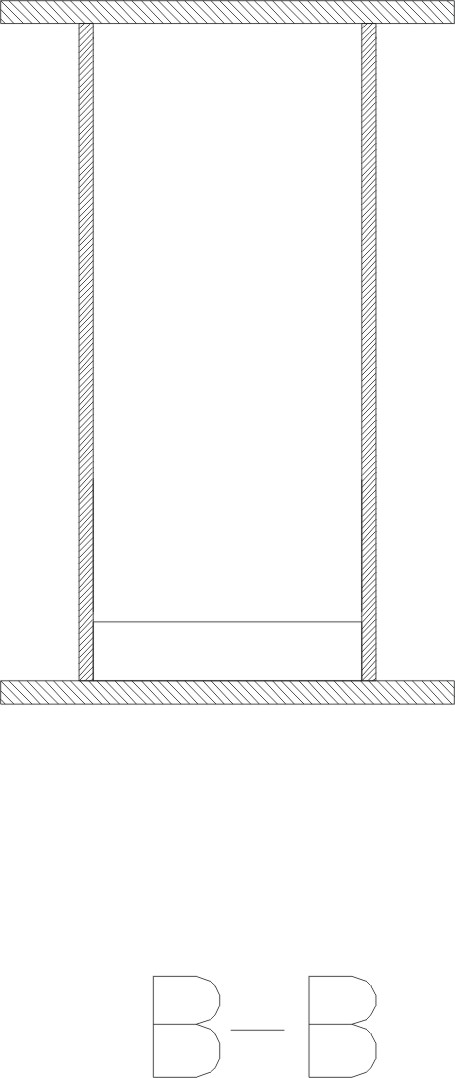

[0017] See details Figure 1-3 , a production process for the precise connection of flanges of large steel structures. The specific operation process is: (1) Flatten the flange surface and spot welding: remove the burr on the flange edge and other surface defects to ensure its fitting accuracy, and The two flanges 3 and 4 are tightly connected and tightly connected, and the two tightly connected flanges are drilled together with a CNC drilling machine, which can ensure the coaxiality of the corresponding holes on the two flanges and facilitate subsequent installation; A number of steel code plates 1 are evenly distributed around the edges of the two flanges by spot welding. The number and spacing of the code plates can be adjusted according to the size of the flanges, so that the two flanges can still ensure go...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com