Method for electrolysis-catalytic oxidation joint treatment on salt-containing organic wastewater

A technology of organic wastewater and catalytic oxidation, which is applied in the fields of oxidized water/sewage treatment, chemical instruments and methods, water/sewage treatment, etc. safe effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

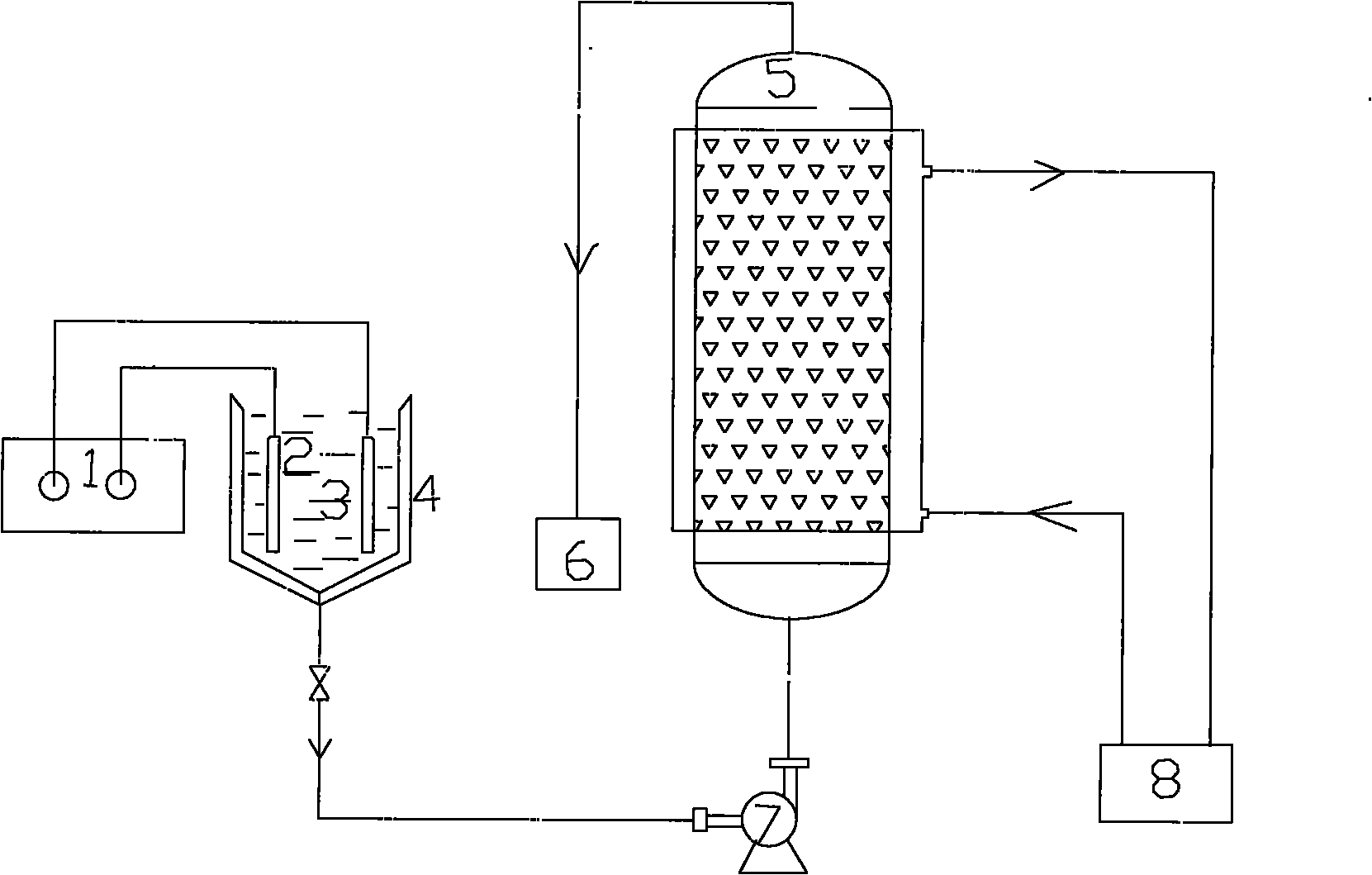

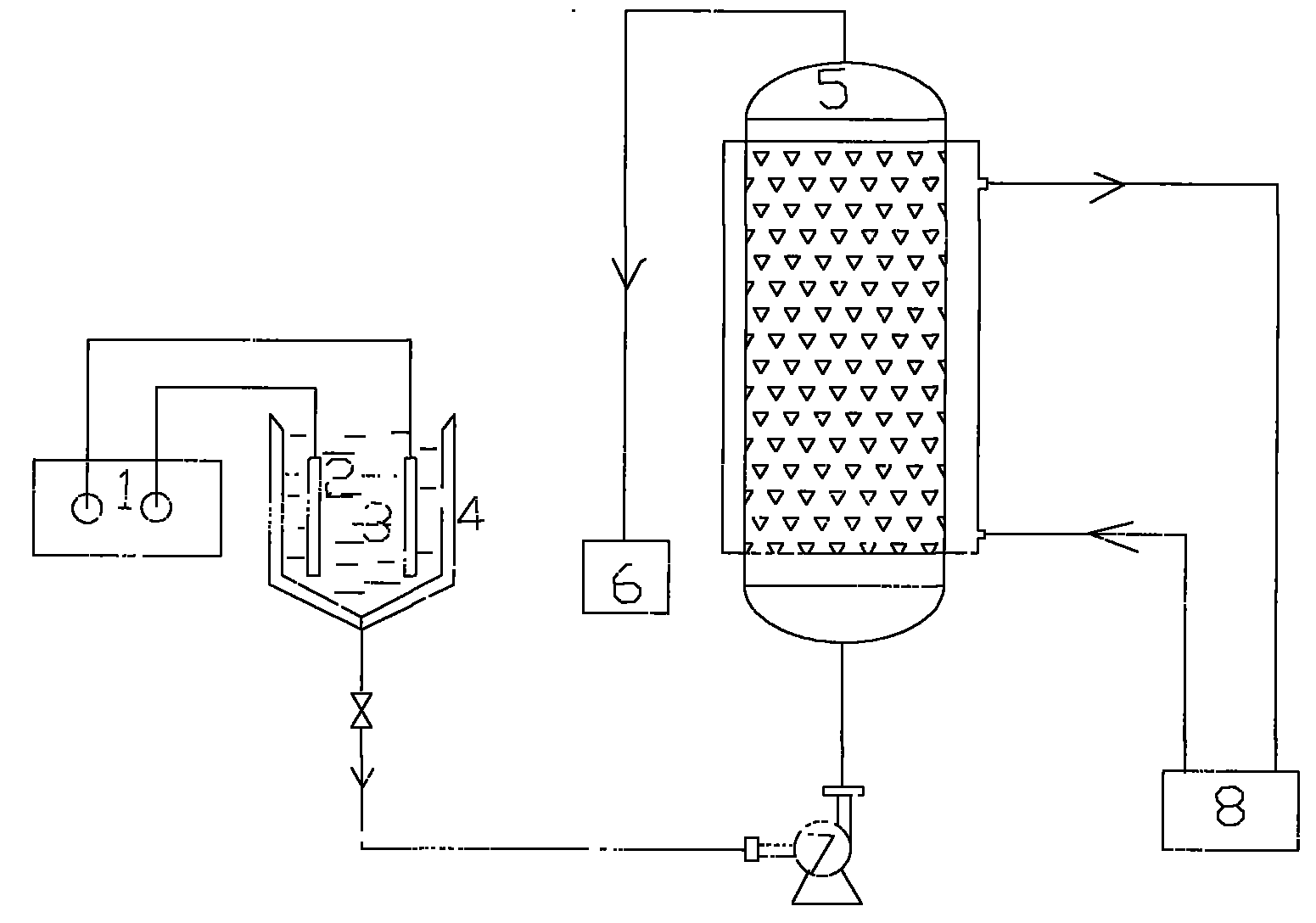

Method used

Image

Examples

Embodiment 1

[0029] Pass 10L of high-salt organic wastewater with an initial COD of 10,000 mg / L into the electrolytic cell, adjust the voltage to 20V, and electrolyze for 20 minutes. Use a peristaltic pump to pump the electrolyzed wastewater into a fixed-bed reactor with 120g of catalyst at a space velocity of 1.6h -1 Continuous flow through the bed for catalytic oxidation reaction. The results are compared with the high-salt wastewater with a certain amount of sodium hypochlorite as an oxidant that is directly catalyzed and oxidized through a fixed bed.

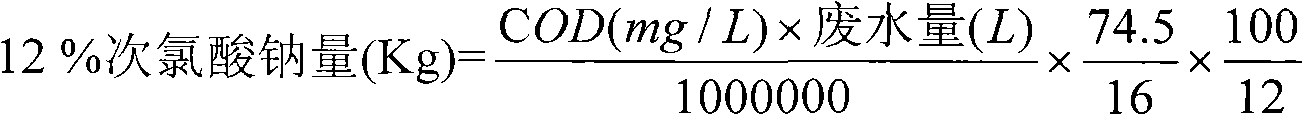

[0030] In the comparative direct oxidation treatment by sodium hypochlorite, the amount of sodium hypochlorite added is determined by the initial COD value of high-salt organic wastewater. Usually calculated as follows:

[0031]

[0032] In practical applications, use 1.2 times the calculation amount.

[0033] COD was determined by the national standard GB11914-89 dichromate method in wastewater. The formula for calculating COD re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com