Low-lead brass and casting method thereof

A lead brass and impurity technology, applied in the field of low lead brass alloy and its casting, can solve the problems of difficult machining, poor fluidity, severe dendrites, etc., and achieve the effect of improving thermal cracking resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

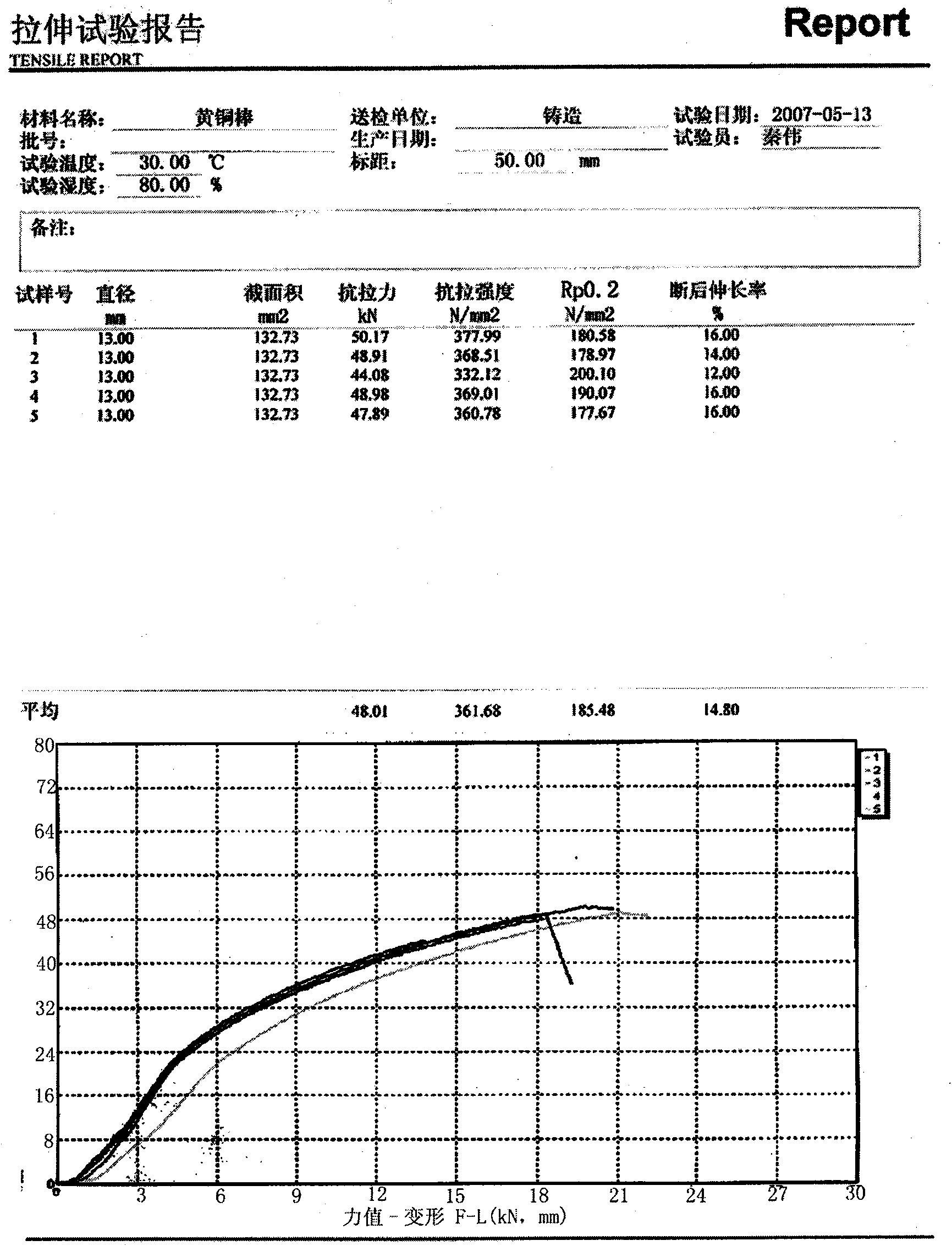

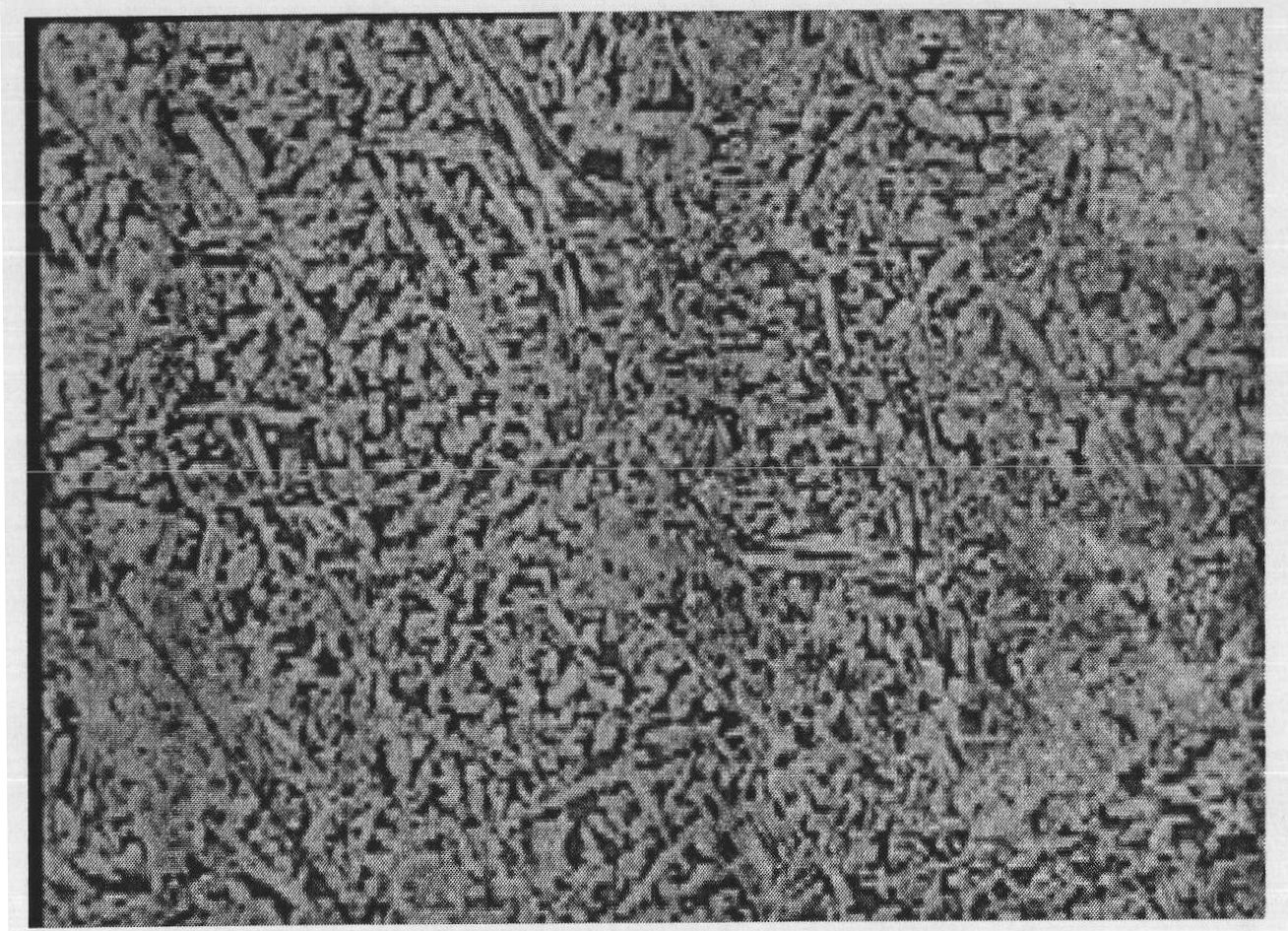

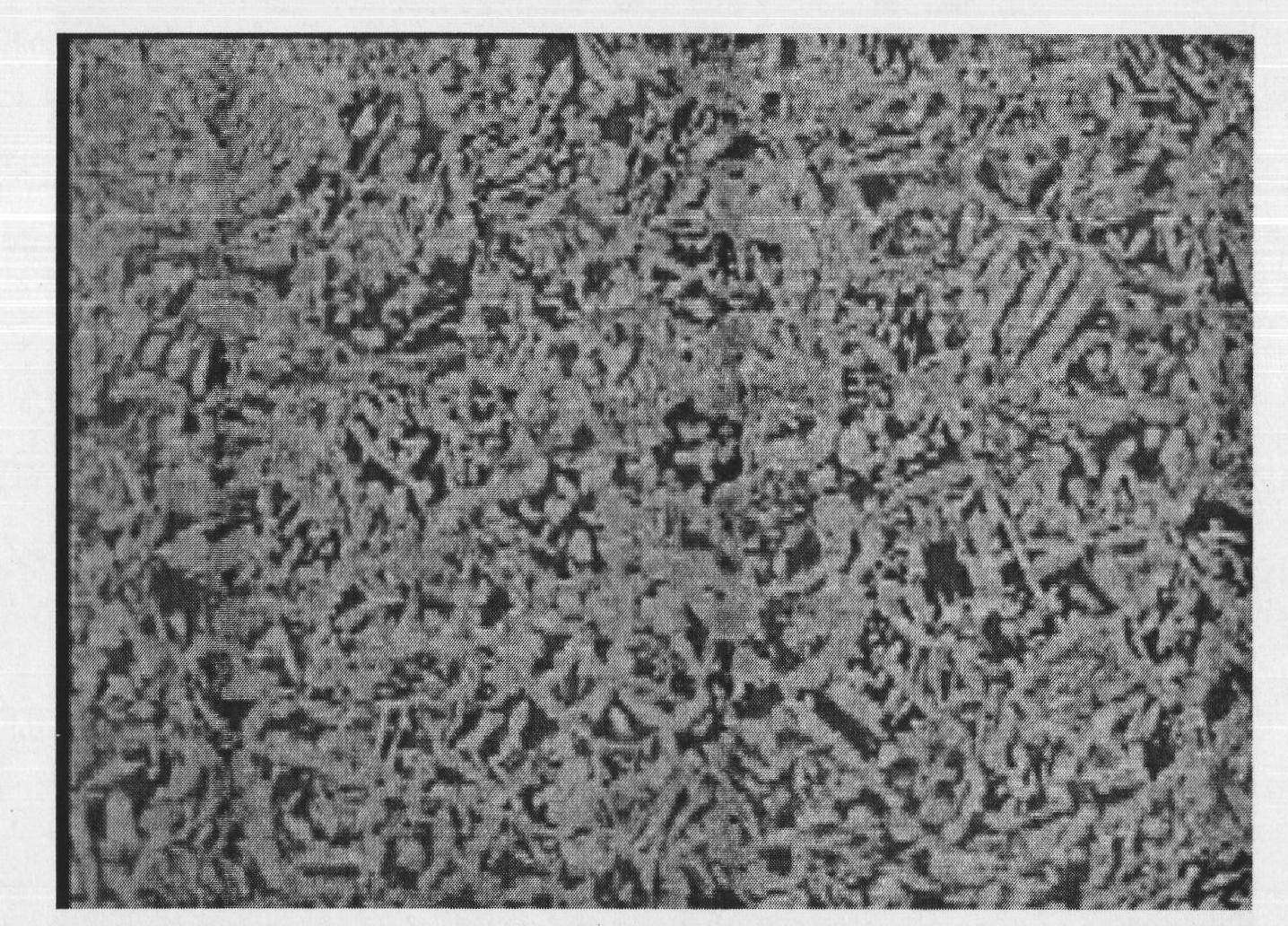

Image

Examples

Embodiment 1

[0021] 59.00% copper, 0.20% iron, 0.025% lead, 0.70% aluminum, 0.10% tin, 0.12% nickel, 0.005% bismuth, 0.025% antimony, 0.50% impurities, and the balance is zinc.

Embodiment 2

[0023] 62.00% copper, 0.10% iron, 0.15% lead, 0.50% aluminum, 0.15% tin, 0.10% nickel, 2.50% bismuth, 0.002% antimony, 0.50% impurities, and the balance is zinc.

Embodiment 3

[0025] 60.00% copper, 0.15% iron, 0.15% lead, 0.60% aluminum, 0.15% tin, 0.10% nickel, 0.04% bismuth, 0.004% antimony, 0.50% impurities, and the balance is zinc.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com