High-temperature vacuum fretting corrosion-wear test bed

A fretting corrosion and wear test technology, applied in the direction of testing wear resistance, can solve the problem of material fretting wear characteristics and mechanism cannot be accurately judged

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Below by non-limiting embodiment and in conjunction with accompanying drawing, invention is further described:

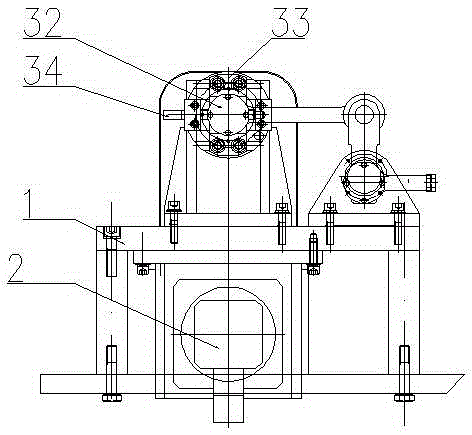

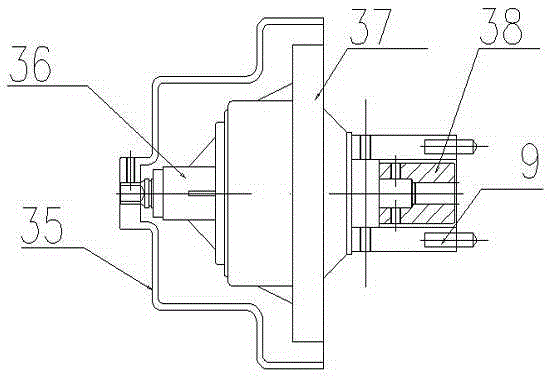

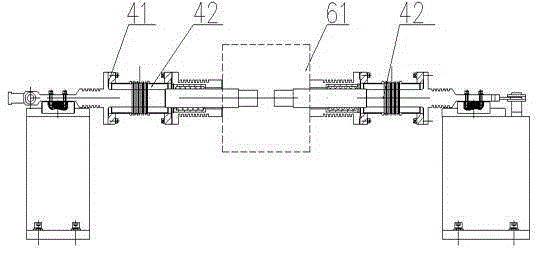

[0022] As shown in the accompanying drawings, a high-temperature vacuum fretting corrosion wear test bench includes a frame 1, a servo motor 2, a displacement adjustment device 3, a displacement actuator 4, a friction measurement mechanism 5, a friction pair system 7, and a test force loading Mechanism 8, lead-bismuth alloy cavity 9, circulating waterway 10, vacuum system 6.

[0023] Frame 1 adopts a welded integrated structure, and the appearance adopts a spray-painted process, which is beautiful and generous overall. Servo motor 2, displacement adjustment device 3, displacement actuator 4, friction force measurement mechanism 5, friction pair system 7, test force loading mechanism 8, lead-bismuth alloy cavity 9, circulating waterway 10, and vacuum system 6 are tightly and stably set in the rack.

[0024] The servo motor 2 adopts a 5Kw Panasonic servo moto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com