Movable three-arm top-assisting anchor rod and anchor cable construction drill carriage

A roofing and anchoring technology, which is applied in the installation of anchoring rods, drilling equipment, earthwork drilling and mining, etc., can solve the problems of unfavorable roadside control, high labor intensity and small workload of employees, so as to reduce the cost of mechanical and electrical maintenance, reduce the The effect of advancing and retreating machine time and reducing auxiliary workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] Describe in detail below in conjunction with accompanying drawing:

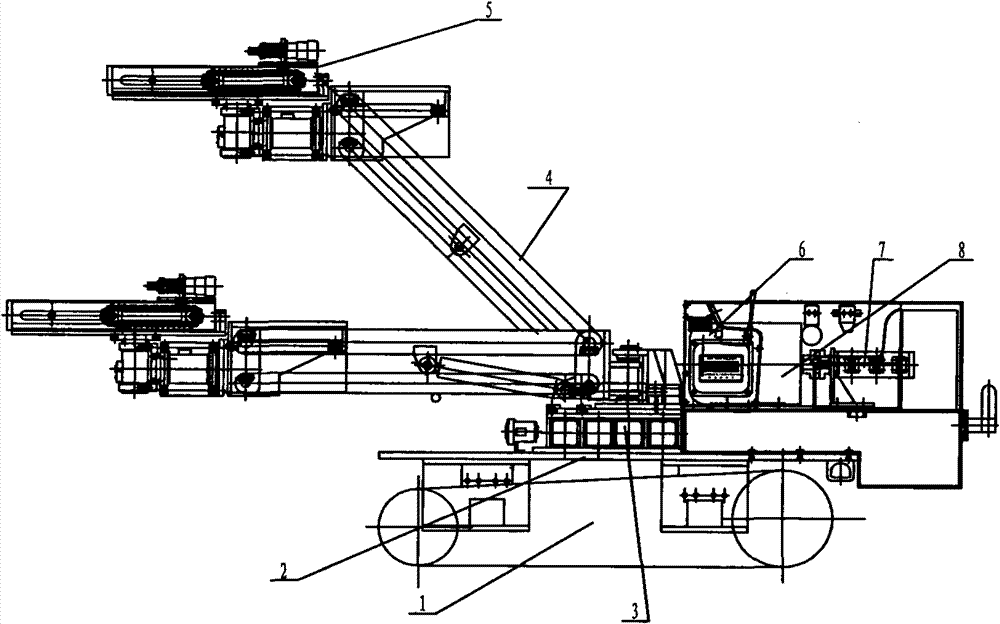

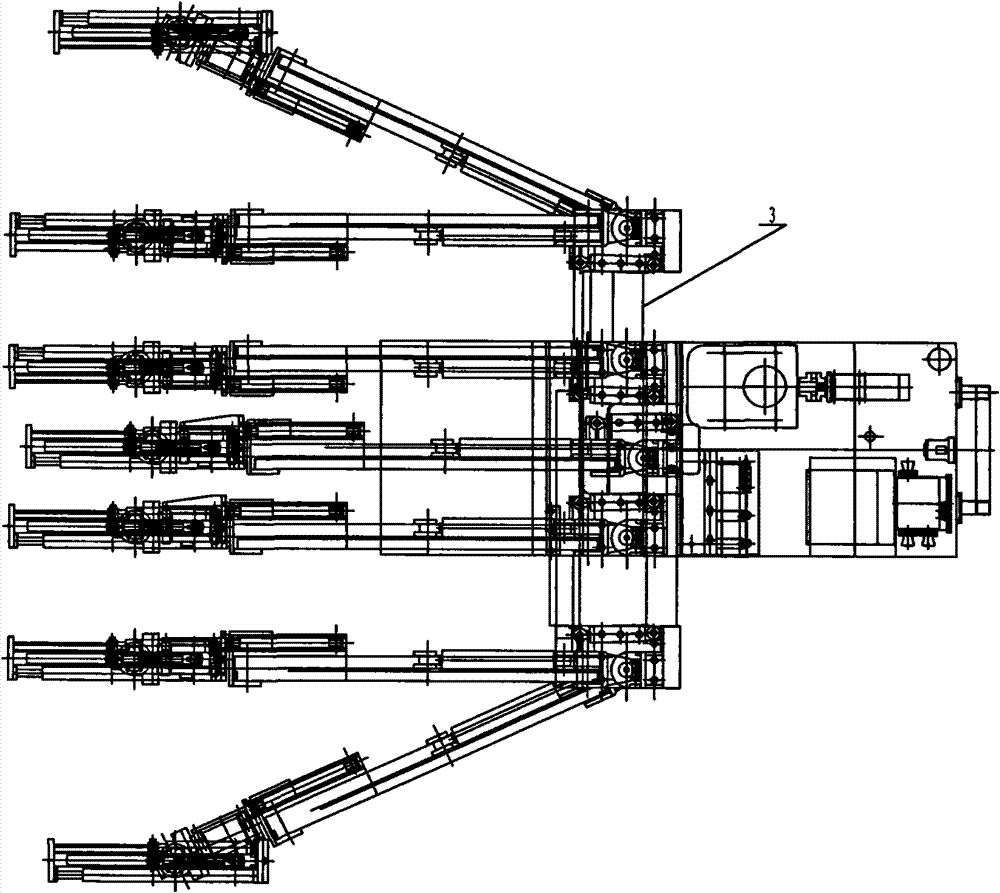

[0041] figure 1 , figure 2 As shown, the movable three-arm roof anchor rod and anchor cable construction drilling vehicle of the present invention. It includes a crawler walking part 1 , a body platform 2 , a base 3 , a drill boom part 4 and a hydraulic drilling rig device 5 , an operating system 6 , a pump station part 7 and an electric motor 8 . The construction drilling rig has three sets of independent drilling boom parts and hydraulic drilling rig devices, which are respectively arranged on the left, middle and right sides of the base 3, and are installed on the base 3, and the base 3 is fixedly installed on the body platform 2; The above-mentioned hydraulic drilling rig device is mounted on the top of the drill arm part. The operating system, the pumping station part, the motor, etc. are installed on the rear part of the body platform 2 .

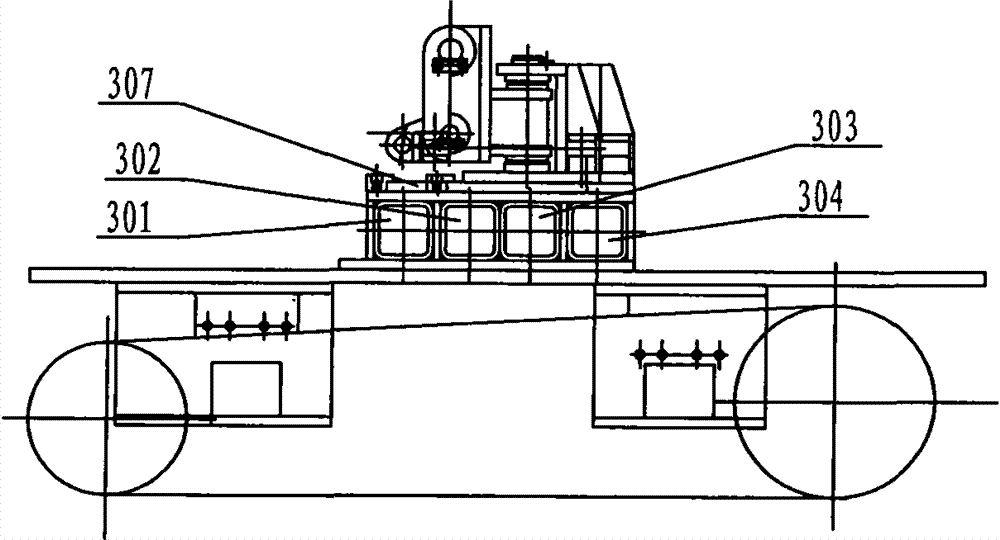

[0042] image 3, Figure 4 As shown, four fixing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com