Lignite drying system

A drying system and lignite technology, applied in the direction of drying solid materials, drying chamber/container, drying gas arrangement, etc., can solve the problems of immature technology and high investment cost, and achieve the effect of high efficiency and low investment cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

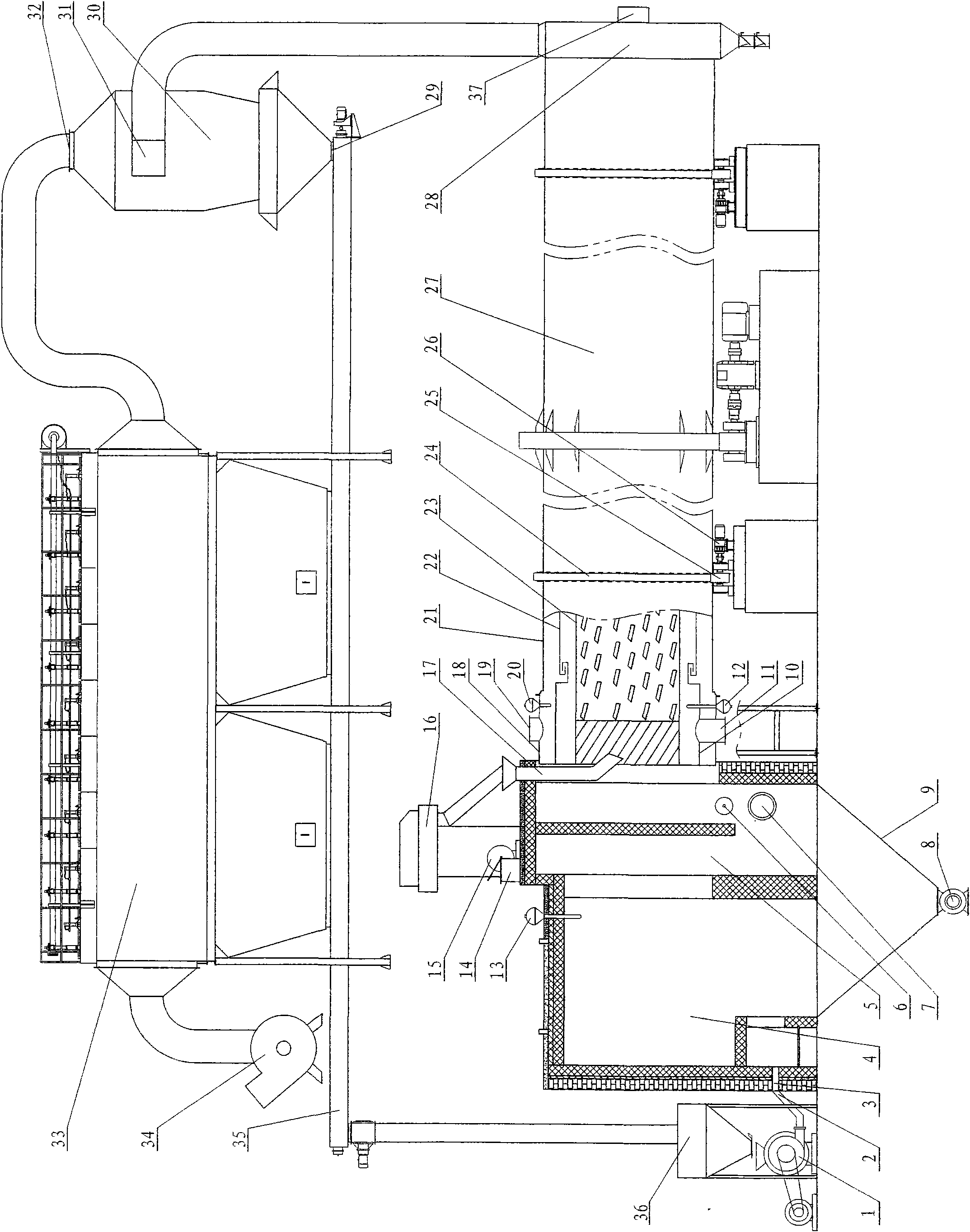

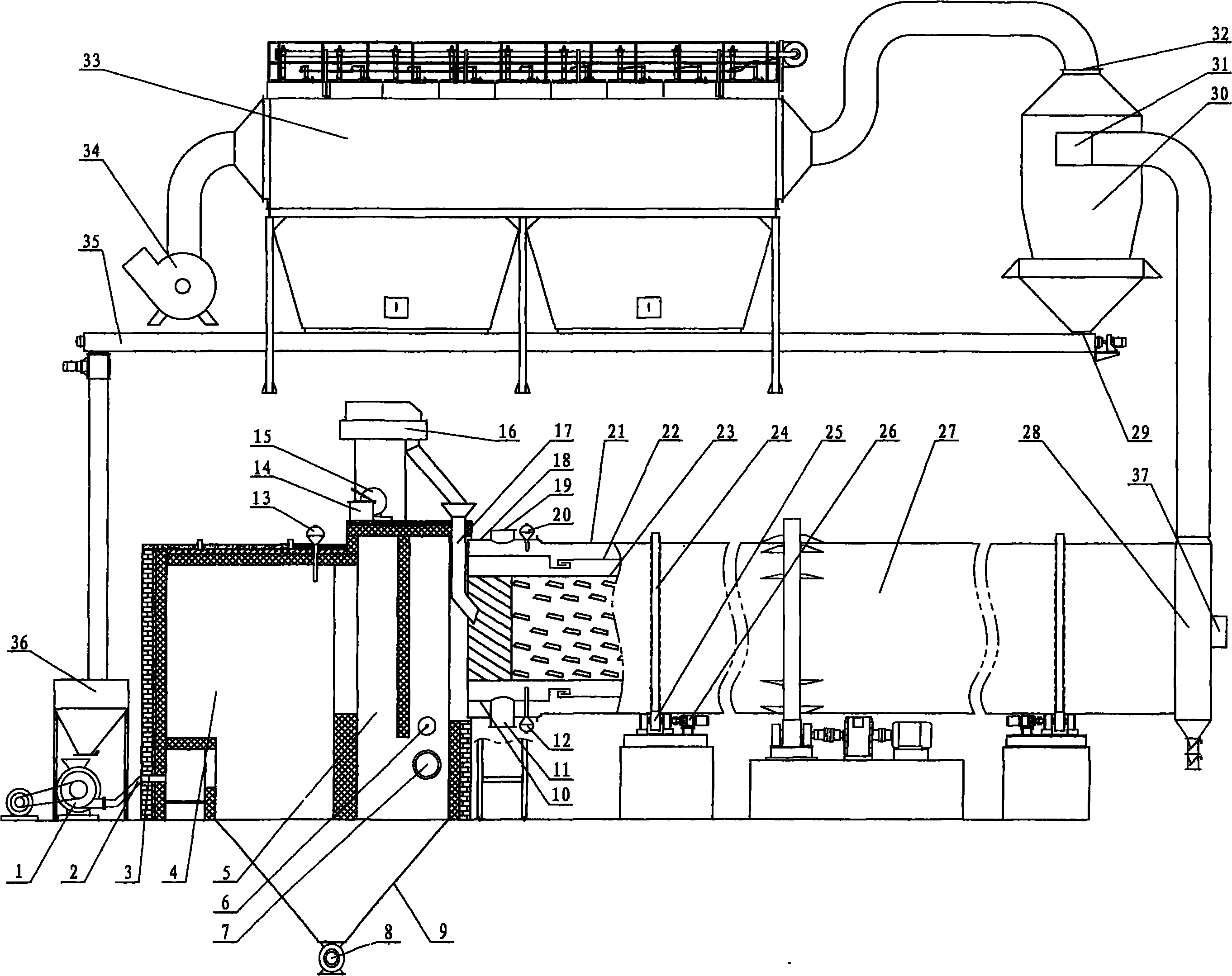

[0013]In the accompanying drawings, a lignite drying system includes a pulverized coal furnace, a three-barrel dryer 27, a hoist 16, a cyclone dust collector 30, a bag filter 33 and a screw conveyor 35. The pulverized coal furnace contains a coal grinding and powder injection device 1 and a combustion chamber 4 . The combustion chamber 4 contains a coal inlet 3 and an air outlet 5 , and the coal outlet 2 of the coal grinding and powder injection device 1 is connected with the coal inlet 3 of the combustion chamber 4 . The three-cylinder dryer 27 includes a feed pipe 17 , an air inlet device, a composite cylinder body, a discharge device 28 and a driving device 26 . The composite cylinder is formed by concentrically fitting three outer cylinders 21 , a middle cylinder 22 and an inner cylinder 23 with different diameters from large to small. The outer cylinder 21 of the composite cylinder is provided with a tire belt 24 , and the tire belt 24 is placed on the support roller 25 ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap