Cathode material of solid oxide fuel cell in A omission type perovskite structure

A fuel cell cathode and solid oxide technology, which is applied in solid electrolyte fuel cells, fuel cells, battery electrodes, etc., can solve problems such as poor stability, achieve good battery performance, and have a wide range of applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

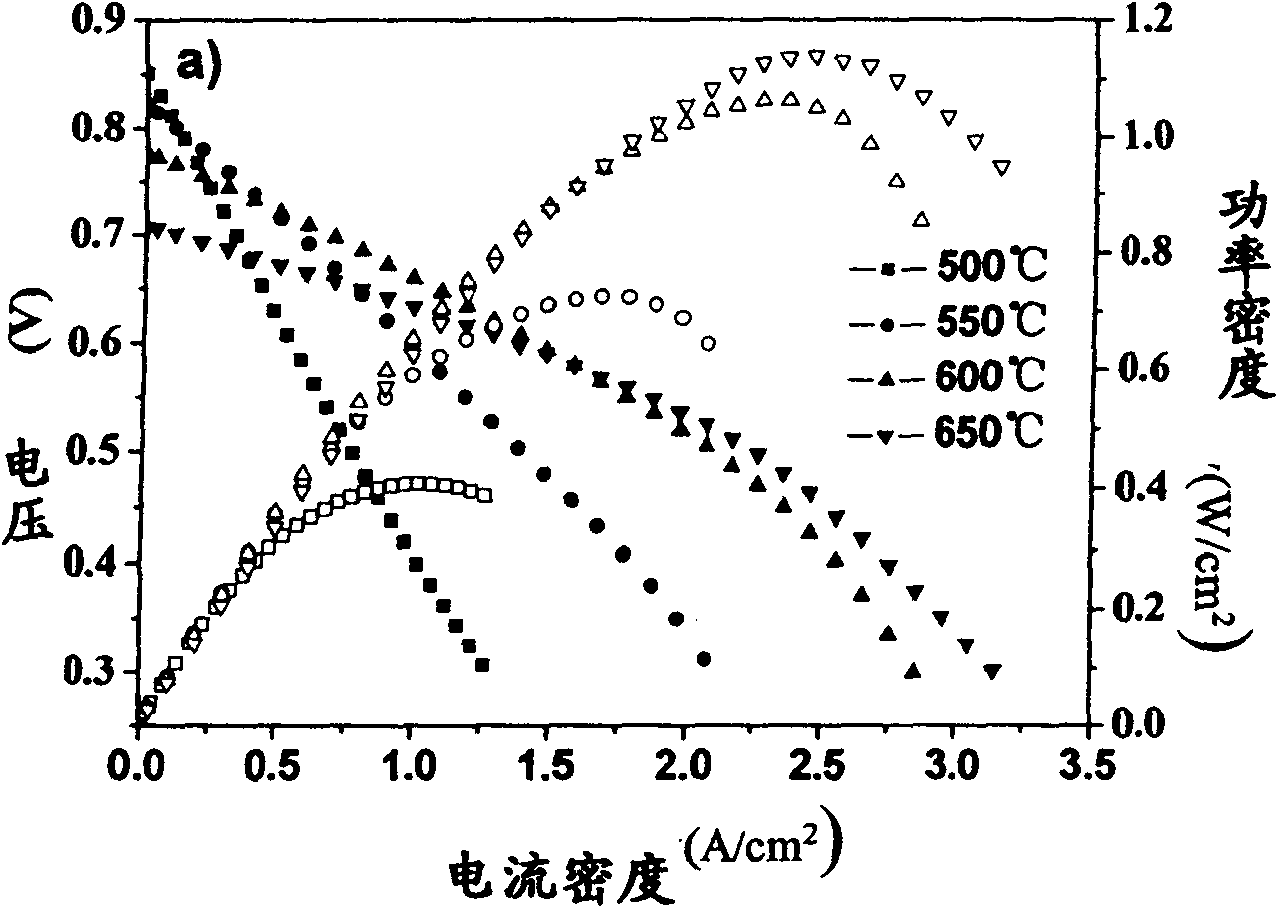

Embodiment 1

[0021] BaCO 3 ,,Co 2 o 3 ,, Fe 2 o 3 and Nb 2 o 5 According to the stoichiometric ratio Ba 0.92 (Co 0.7 Fe 0.2 Nb 0.1 )O 3-δ Mix, add alcohol and ball mill for 24 hours to obtain the precursor. After the precursor was dried, it was sintered in the air at 1100°C for 6 hours, and the powder was obtained by solid phase synthesis for the outer layer of the battery cathode; the Ba(NO 3 ) 2 , Co(NO 3 ) 2 .6H 2 O, Fe(NO 3 ) 3 .9H 2 O and NbO(C 2 o 4 ) 3 According to the stoichiometric ratio Ba0.92 (Co 0.7 Fe 0.2 Nb 0.1 )O 3-δ Mix, add water to dissolve, add citric acid with the same molar amount of total metal ions, heat and stir at 90°C until it becomes sol or gel, and finally sinter in air at 800°C for 5 hours to obtain nanopowder for battery cathode inner layer. In the following examples, the electrolyte powder in the anode-supported half-cell is obtained by solid-phase synthesis, the anode and the electrolyte are respectively obtained by casting method, ...

Embodiment 2

[0023] BaCO 3 ,,Co 2 o 3 ,, Fe 2 o 3 and Nb 2 o 5 According to the stoichiometric ratio Ba 0.95 (Co 0.6 Fe 0.3 Nb 0.1 )O 3-δ Mix, add alcohol and ball mill for 48 hours to obtain the precursor. After the precursor was dried, it was sintered in the air at 1000°C for 12 hours, and the powder was obtained by solid phase synthesis for the outer layer of the battery cathode; the Ba(NO 3 ) 2 , Co(NO 3 ) 2 .6H 2 O, Fe(NO 3 ) 3 .9H 2 O and NbO(C 2 o 4 ) 3 According to the stoichiometric ratio Ba 0.95 (Co 0.6 Fe 0.3 Nb 0.1 )O 3-δ Mix, add water to dissolve, add citric acid with the same molar amount of total metal ions, heat and stir at 80-100°C until it becomes a sol or gel, and finally sinter at 800°C in air for 5 hours to obtain nanopowder for use in The inner layer of the battery cathode. Fabrication of Ba by coating on NiO-SSZ(500μm) / SSZ(10μm) anode-supported half-cells 0.95 (Co 0.6 Fe 0.3 Nb 0.1 )O 3-δ The cathode is sintered at 900°C for 5 hours. ...

Embodiment 3

[0025] BaCO 3 ,,Co 2 o 3 ,, Fe 2 o 3 and V 2 o 5 According to the stoichiometric ratio Ba 0.99 (Co 0.7 Fe 0.2 V 0.1 )O 3-δ Mix, add alcohol and ball mill for 48 hours to obtain the precursor. After the precursor was dried, it was sintered in air at 1100°C for 24 hours, and the powder was obtained by solid phase synthesis for the outer layer of the battery cathode; the Ba(NO 3 ) 2 , Co(NO 3 ) 2 .6H 2 O, Fe(NO 3 ) 3 .9H 2 O and C 10 o 20 V 2 According to the stoichiometric ratio Ba 0.99 (Co 0.7 Fe 0.2 V 0.1 )O 3-δ Mix, add water to dissolve, add citric acid twice the molar amount of the total metal ions, heat and stir at 80-100°C until it becomes sol or gel, and finally sinter in air at 800°C for 6 hours to obtain nano-pure cathode powder body; the Sm(NO 3 ) 3 .6H 2 O, Ce(NO 3 ) 3 .6H 2 Mix and dissolve O in water, add glycine with 2 times the molar amount of total metal ions, burn at high temperature to obtain precursor powder, and then sinter at...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com