Rare-earth ion doped gadolinium gallium garnet porous nano-belt and preparation method thereof

A technology of gadolinium gallium garnet and rare earth ions, applied in the field of nanomaterial preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

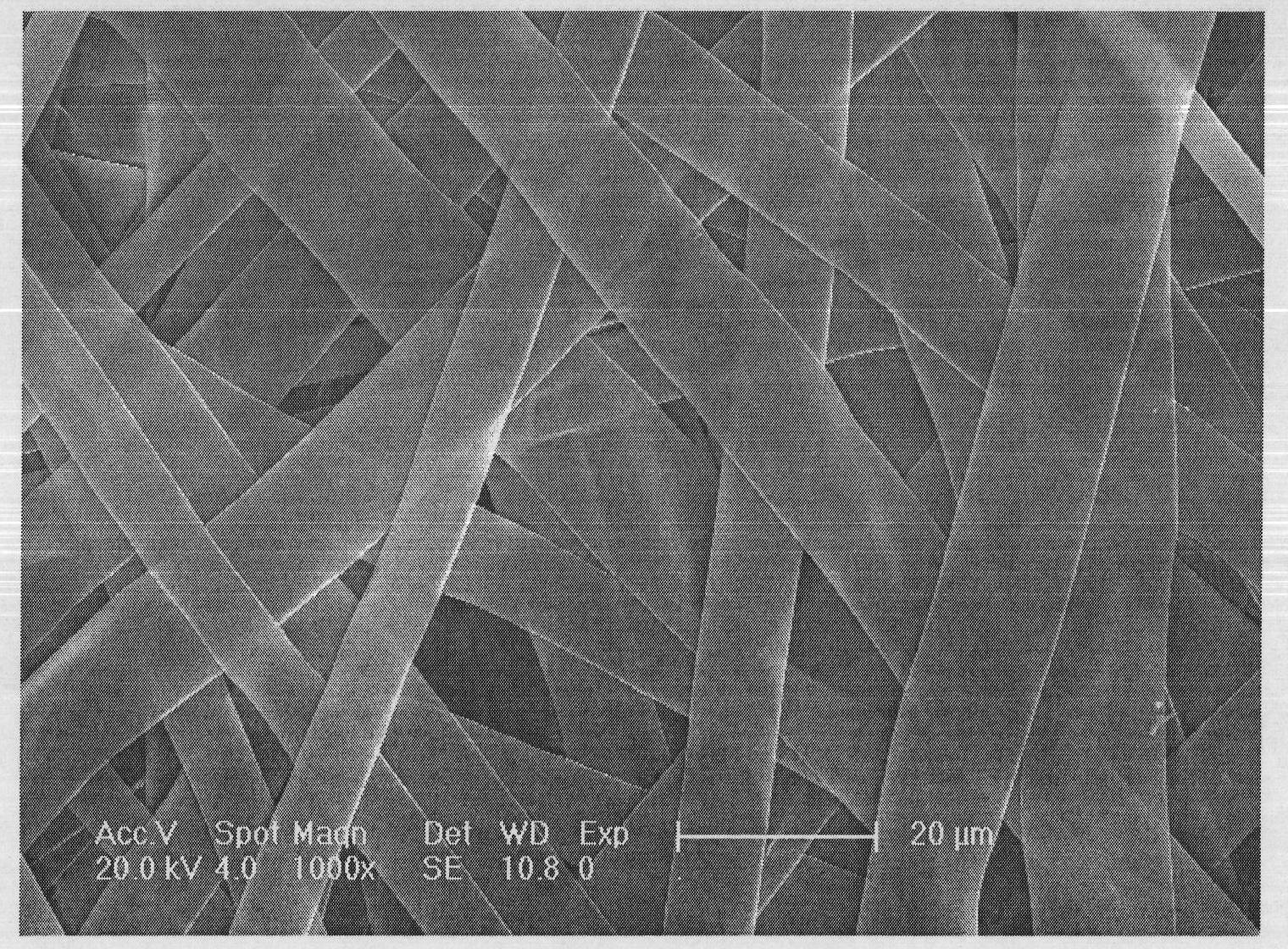

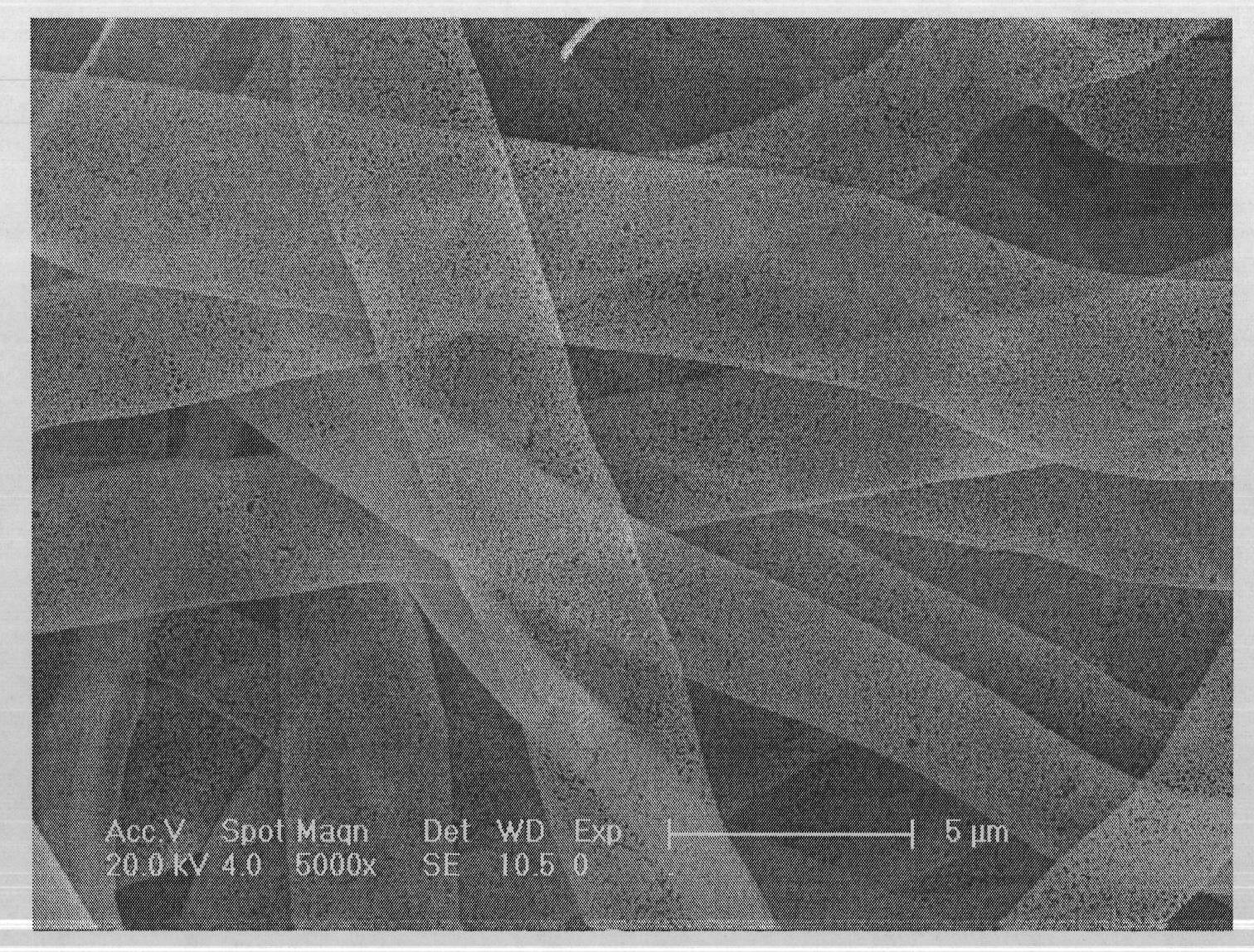

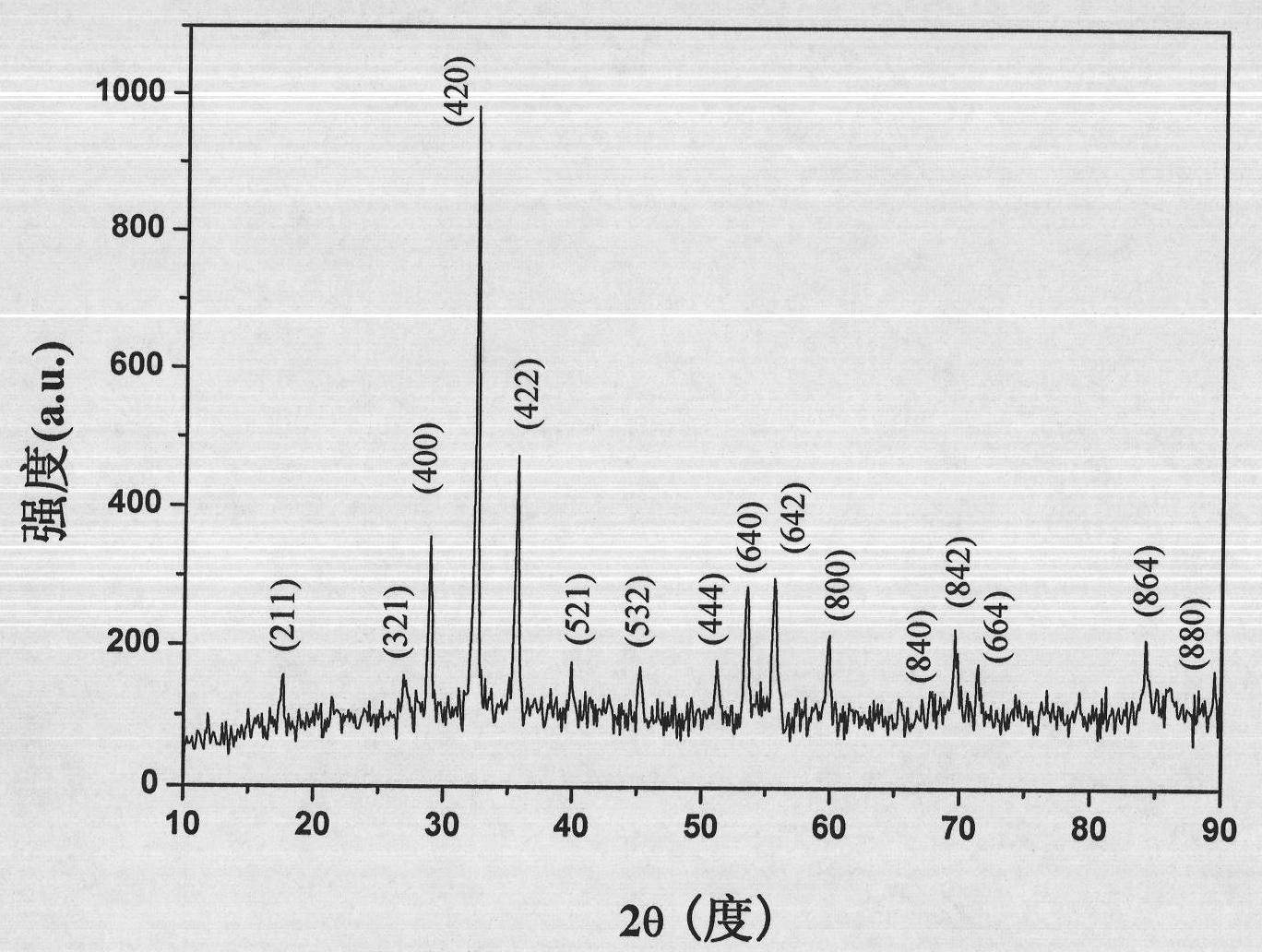

[0029] Embodiment 1: with Gd 2 o 3 and Ga 2 o 3 For raw materials, press Gd 3+ with Ga 3+ The amount ratio of the substances is 3:5 and the raw materials are weighed. Heat to dissolve with concentrated nitric acid, and remove excess nitric acid by heating. A certain proportion of Gd(NO 3 ) 3 and Ga(NO 3 ) 3 solution. Weigh an appropriate amount of polyvinylpyrrolidone and add it to the above solution, put it on a digital magnetic stirrer at room temperature and stir for 12 hours, the PVP is completely dissolved, and then put it in a closed container and let it stand for 4 hours until the solution is clear and no bubbles exist, and you get Uniform, transparent and viscous precursor sol. Wherein the nitrate content is 6% (wt%), the PVP content is 30% (wt%), and the DMF content is 64% (wt%). Add the prepared spinning solution into the syringe of the spinning device to carry out electrospinning. The inner diameter of the needle is 1.2 mm, the needle is downward, vertic...

Embodiment 2

[0030] Embodiment 2: with Gd 2 o 3 , Ga 2 o 3 and Eu 2 o 3 For raw materials, press Gd 3+ with Eu 3+ The molar ratio of the substance is 95:5, according to [Gd 3+ +Eu 3+ ] with Ga 3+ The amount ratio of the substances is 3:5 and the raw materials are weighed. Heat to dissolve with concentrated nitric acid, and remove excess nitric acid by heating. A certain proportion of Gd(NO 3 ) 3 , Ga(NO 3 ) 3 and Eu(NO 3 ) 3 solution. Weigh an appropriate amount of polyvinylpyrrolidone and add it to the above solution, put it on a digital magnetic stirrer at room temperature and stir for 6 hours, the PVP is completely dissolved, then place it in a closed container and let it stand for 2 hours until the solution is clear and no bubbles exist, that is, Uniform, transparent and viscous precursor sol. Wherein the nitrate content is 8% (wt%), the PVP content is 28% (wt%), and the DMF content is 64% (wt%). Add the prepared spinning solution into the syringe of the spinning dev...

Embodiment 3

[0031] Embodiment 3: with Gd 2 o 3 , Ga 2 o 3 , Yb 2 o 3 、Er 2 o 3 as the raw material, according to the ratio of the amount of substance to Gd 3+ :Yb3+ :Er 3+ =91:8:1 Weigh the raw materials to meet the requirements of [Gd 2 o 3 +Yb 2 o 3 +Er 2 o 3 ] with Ga 2 o 3 The molar ratio is 3:5. Dissolve it by heating with concentrated nitric acid, and then remove excess nitric acid to obtain nitrate. A certain proportion of Gd(NO 3 ) 3 , Yb(NO 3 ) 3 , Er(NO 3 ) 3 and Ga(NO 3 ) 3 solution. Weigh a certain amount of polyvinylpyrrolidone and add it to the above solution, put it on a magnetic stirrer at room temperature and stir for 6 hours, after the PVP is completely dissolved, then place it in an airtight container and let it stand for 4 hours until the solution is clear and no bubbles exist. That is, a uniform, transparent and viscous precursor sol is obtained. The mass fractions of nitrate, PVP and DMF were 10%, 26% and 64%, respectively. Add the prepare...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com