Magnon crystal magnetic sensor and preparation method thereof

A magnetic sensor and magnon technology, applied in the field of magnetic sensing, can solve the problems of easy damage, irregular etching patterns, high cost, etc., and achieve the effects of improving temperature stability, simple preparation process, and simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

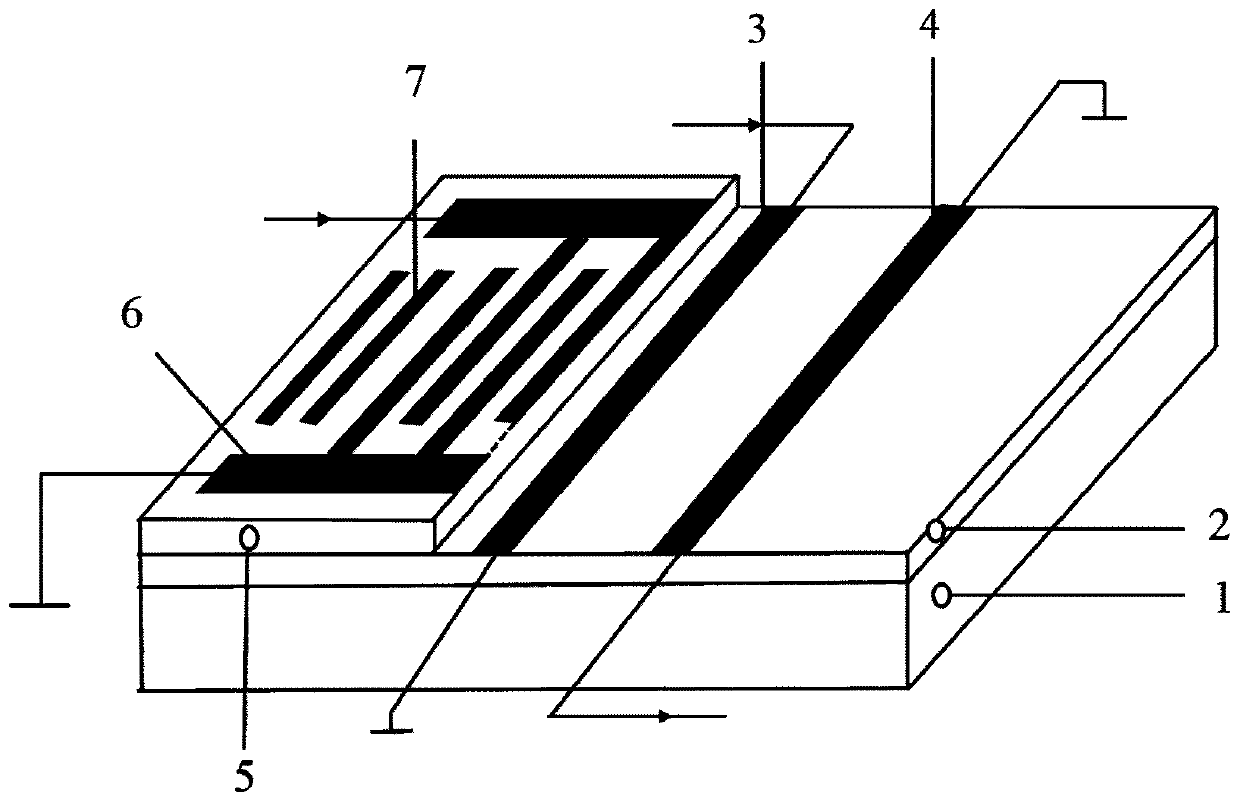

[0025] A method for preparing a magnon crystal magnetic sensor, specifically comprising the following steps:

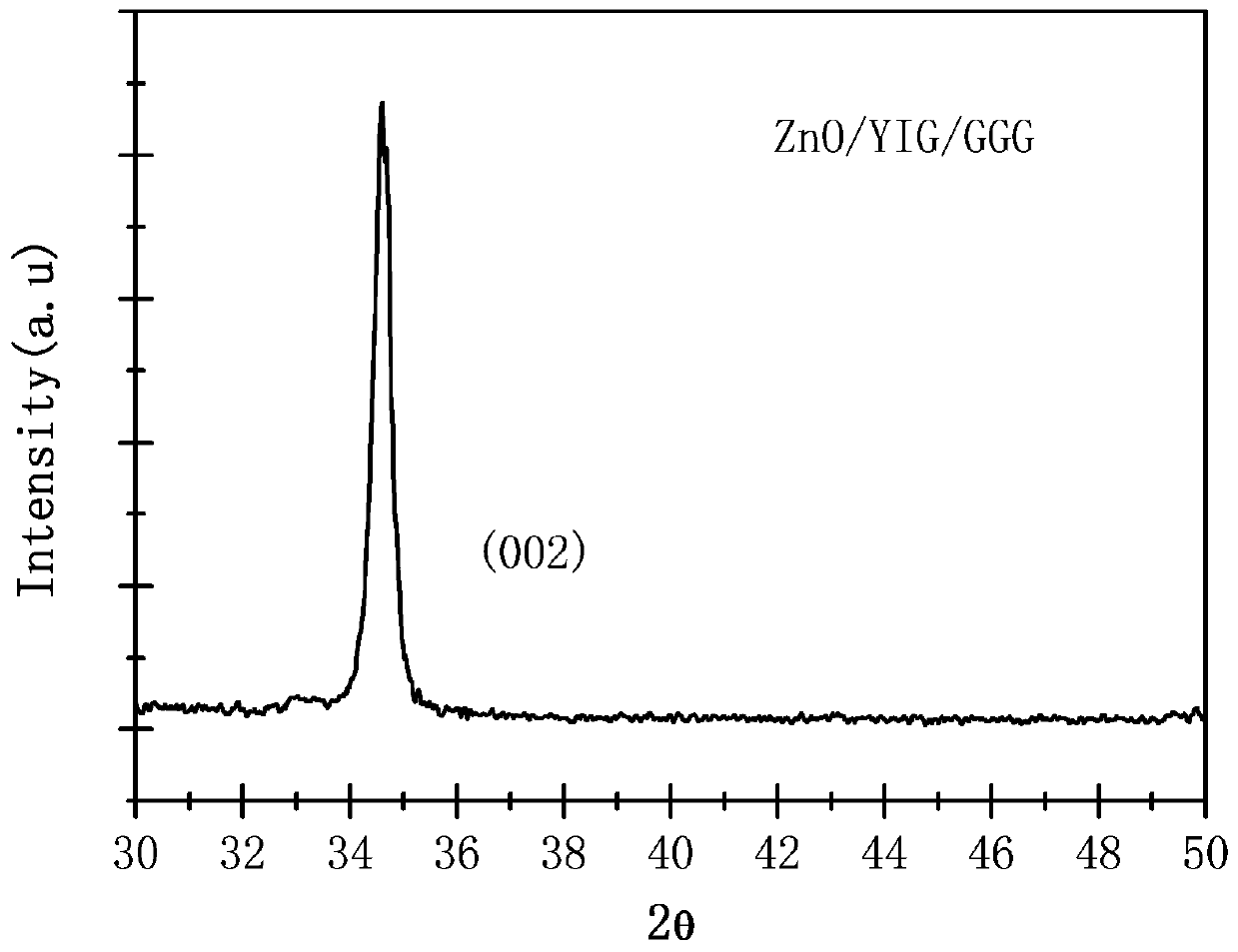

[0026] Step 1, growing a yttrium iron garnet (YIG) film on a gadolinium gallium garnet substrate (GGG) by liquid phase epitaxy to obtain a substrate with YIG;

[0027] Step 2, cleaning: first, soak the substrate with YIG obtained in step 1 in a mixture of concentrated sulfuric acid and hydrogen peroxide with a volume ratio of 1:1 for 20 minutes, take it out and rinse it with deionized water; then, clean the substrate in the previous step Soak the substrate in a mixture of ammonia, hydrogen peroxide and deionized water with a volume ratio of 1:1:5 for 20 minutes, take it out and rinse it with deionized water; finally, clean it ultrasonically in acetone and ethanol in turn, and dry it with nitrogen gas for later use ;

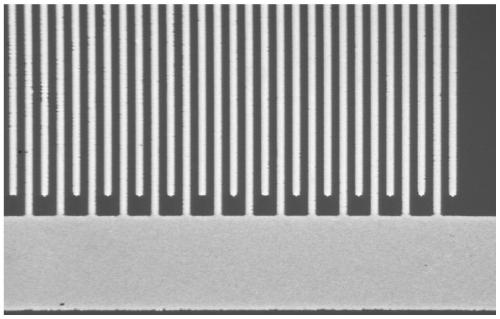

[0028] Step 3, use photolithography to form antenna patterns on the YIG substrate cleaned in step 2, then use magnetron sputtering to deposit platinum ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com