Novel technology for preparing organic fertilizer by using waste bamboo shoot hulls

A technology of organic fertilizer and bamboo shoot shells, which is applied in the field of preparing new organic fertilizers, can solve problems such as affecting agricultural effects, and achieve the effects of reducing costs, extending the industrial chain and improving quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

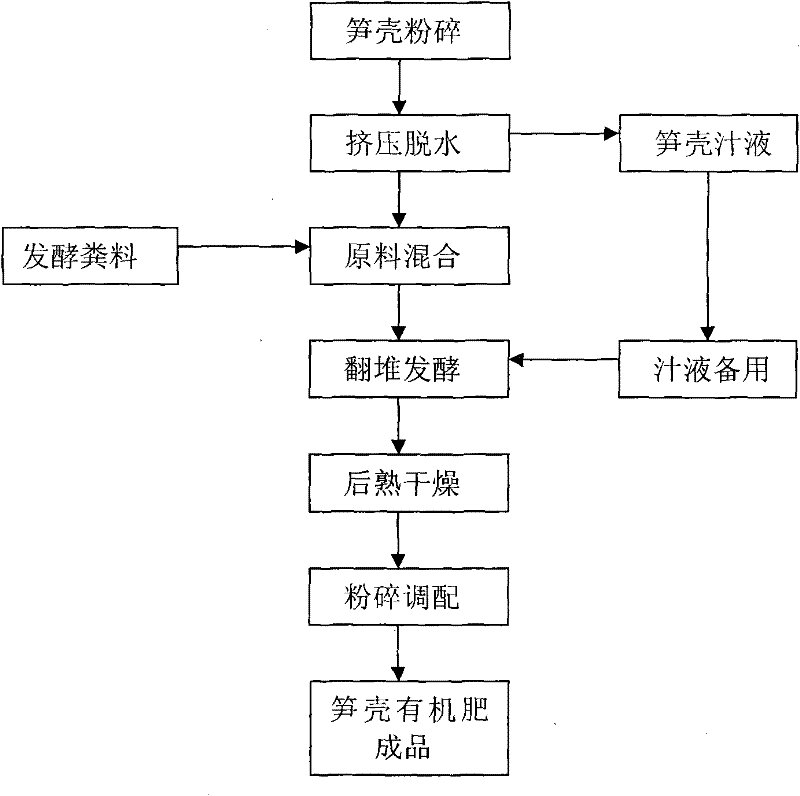

Image

Examples

Embodiment 1

[0028] Take 60 parts of dehydrated bamboo shoot shells and 40 parts of fermented cow dung; adjust the water content to 65%, mix evenly, and place in a fermentation tank. After the temperature rises to about 60°C, it must be turned once a day, and twice in the morning and evening when the temperature is high. After 15-25 days of fermentation, it is naturally dried to a moisture content of 10-20%, crushed, and packaged to become a finished product of bamboo shoot organic fertilizer. The bamboo shoot shell organic fertilizer is used as a base fertilizer and applied to the broccoli field in the organic vegetable demonstration area, which can significantly improve the soil structure, promote the nutrient absorption of the broccoli, improve the disease resistance and fruit quality of the broccoli, and increase the yield by 10-15% per mu.

Embodiment 2

[0030] Take 70 parts of dehydrated bamboo shoot shells and 30 parts of fermented sheep manure; adjust the water content to 60%, stack and ferment for 15-20 days, dry to about 10% water content, crush, and granulate with an extrusion granulator to form bamboo shoots The shell organic fertilizer is a finished product, and the moisture content of the granulated organic fertilizer is controlled within 5%. Applying the bamboo shoot organic fertilizer to the organic tea garden can significantly improve the soil structure, improve the organic carbon content of the tea garden soil, and promote the germination of morning tea.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| water content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com