Polyurethane elastomer and preparation method thereof

A technology of polyurethane elastomers and poly pairs, which is applied in the field of polyurethane elastomers, can solve the problems of relatively large influence of coating aging performance, and achieve the effects of being conducive to sustainable development of the environment, reducing costs, and unsafe operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

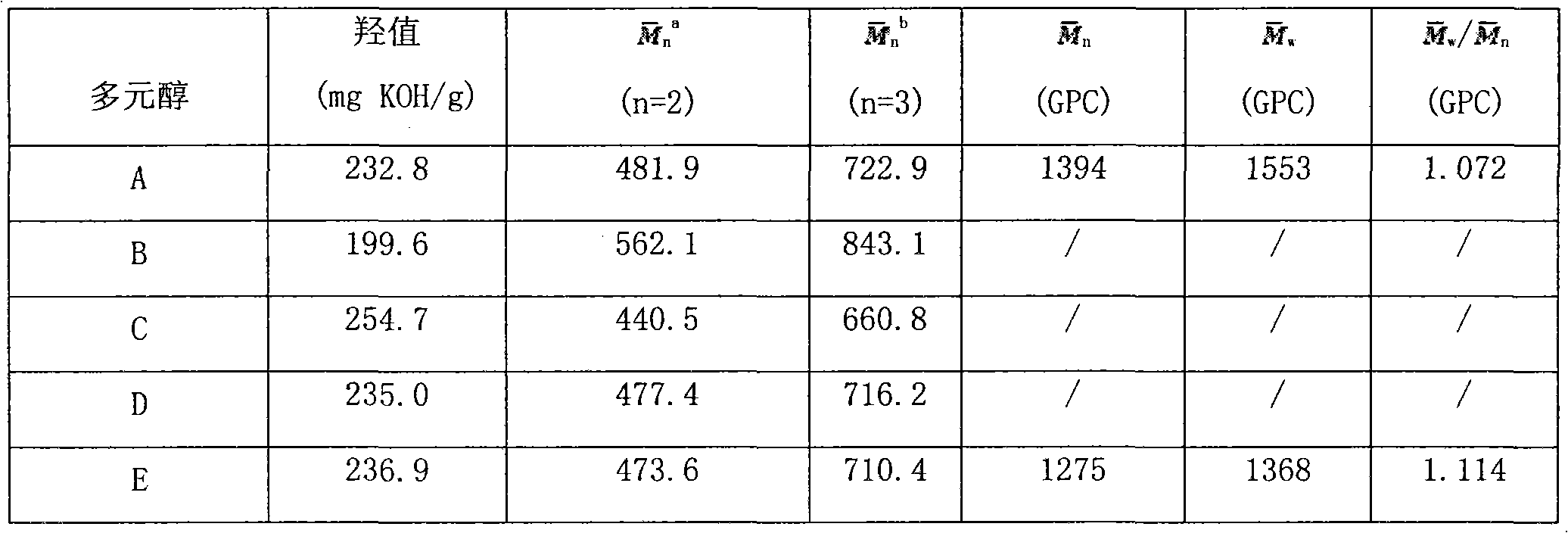

[0026] Clean and dry 300g of waste PET roll film, crush it into 5mm×5mm pieces, heat it at 100°C for 20min by infrared, add 350g of TEG, 3g of n-butyltin dilaurate, and heat it under 500W microwave at normal pressure Irradiate under low temperature for 8 minutes, wait for cooling, then add 300g castor oil, irradiate for 20min under 500W microwave normal pressure, then dehydrate in vacuum for 2h in an oil bath at 140°C, and obtain light yellow room temperature flowable liquid complex polyol A. The above process does not need nitrogen protection, and the hydroxyl value and molecular weight of the obtained complex polyol A are shown in Table 1.

[0027] Mix 33g of complex polyol A with 300g of PTMG1000, vacuum dehydrate at 110°C for 2h; cool to 40°C, add 130g of 2,4-TDI, react at 75°C for 2h, defoam for 0.5h, the NCO% of the obtained prepolymer It is 6.84%; heat up to 90°C, add 82g of preheated and molten MOCA, stir evenly, defoam for 5 minutes, pour into a preheated mold, solidi...

Embodiment 2

[0030]Clean and dry 300g of waste plastic bottles, crush them into pieces of 5mm×5mm, heat them by infrared at 90°C for 30min, add 400g of PEG200, 3g of n-butyltin dilaurate, and put them under 500W microwave normal pressure Irradiate for 8 minutes, wait for cooling, then add 300g castor oil, irradiate for 20 minutes under 500W microwave normal pressure, and then dehydrate in vacuum for 2 hours in an oil bath at 140°C to obtain light yellow liquid composite polyol B that can flow at room temperature. The above process does not need nitrogen protection, and the hydroxyl value and molecular weight of the obtained composite polyol B are shown in Table 1.

[0031] Mix 107.1g of complex polyol B with 250g of PTMG1000, vacuum dehydrate at 120°C for 1.5h; cool to 40°C, add 154g of 2,4-TDI, react at 70°C for 3h, defoam for 0.5h, the obtained prepolymer NCO% is 6.656%; heat up to 90°C, add 89.3g of preheated and molten MOCA, stir evenly, defoam for 4min, pour into a preheated mold, cur...

Embodiment 3

[0033] 300 parts by weight of waste PET plastic bottles were cleaned, dried, crushed into 5mm×5mm fragments, heated by infrared at 100°C for 20min, added 300g of DEG, 2.6g of n-butyltin dilaurate, and heated under 550W microwave Press down and irradiate for 7 minutes, wait for cooling, then add 180g of castor oil, irradiate for 17min under 550W microwave normal pressure, and then dehydrate in vacuum for 2h in an oil bath at 140°C to obtain light yellow liquid complex polyol C that can flow at room temperature . The above process does not require nitrogen protection, and the hydroxyl value and molecular weight of the obtained composite polyol C are shown in Table 1.

[0034] Mix 33g of C complex polyol with 300g of PTMG1000, vacuum dehydrate at 120°C for 1.5h; cool to 40°C, add 130g of 2,4-TDI, react at 73°C for 2.5h, defoam for 0.5h, the obtained prepolymer NCO% is 6.84%; heat up to 95°C, add 82g of preheated and molten MOCA, stir evenly, defoam for 5min, pour into a preheate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| 100% modulus stress | aaaaa | aaaaa |

| 300% modulus stress | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com