Er<3+>/Yb<3+>codoped mayenite upconversion fluorescent powder and preparation method thereof

A technology of dodecacalcium and phosphor powder, applied in the field of materials, can solve problems such as insufficient stability, and achieve the effects of easy mass production, pollution-free preparation method and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

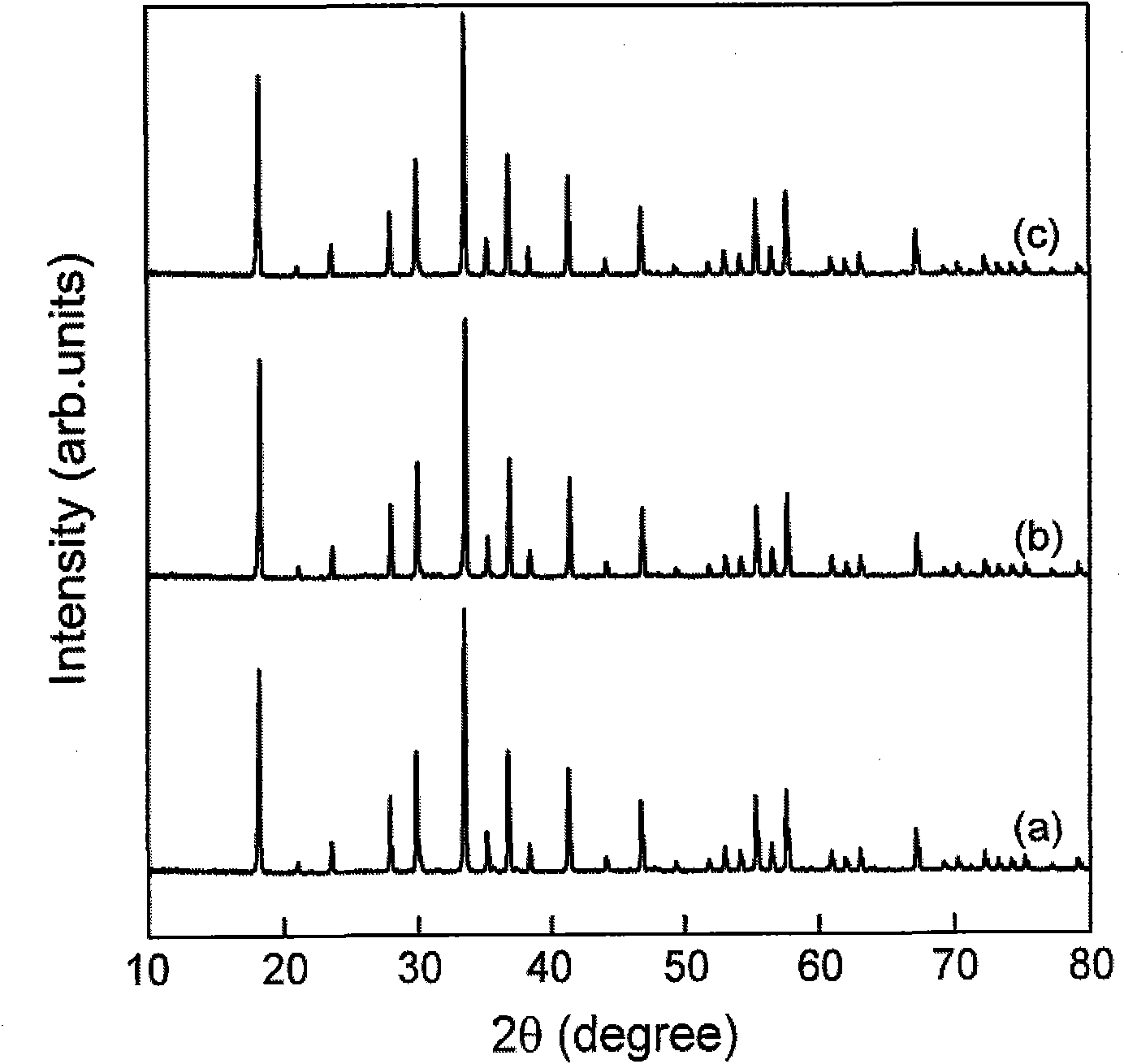

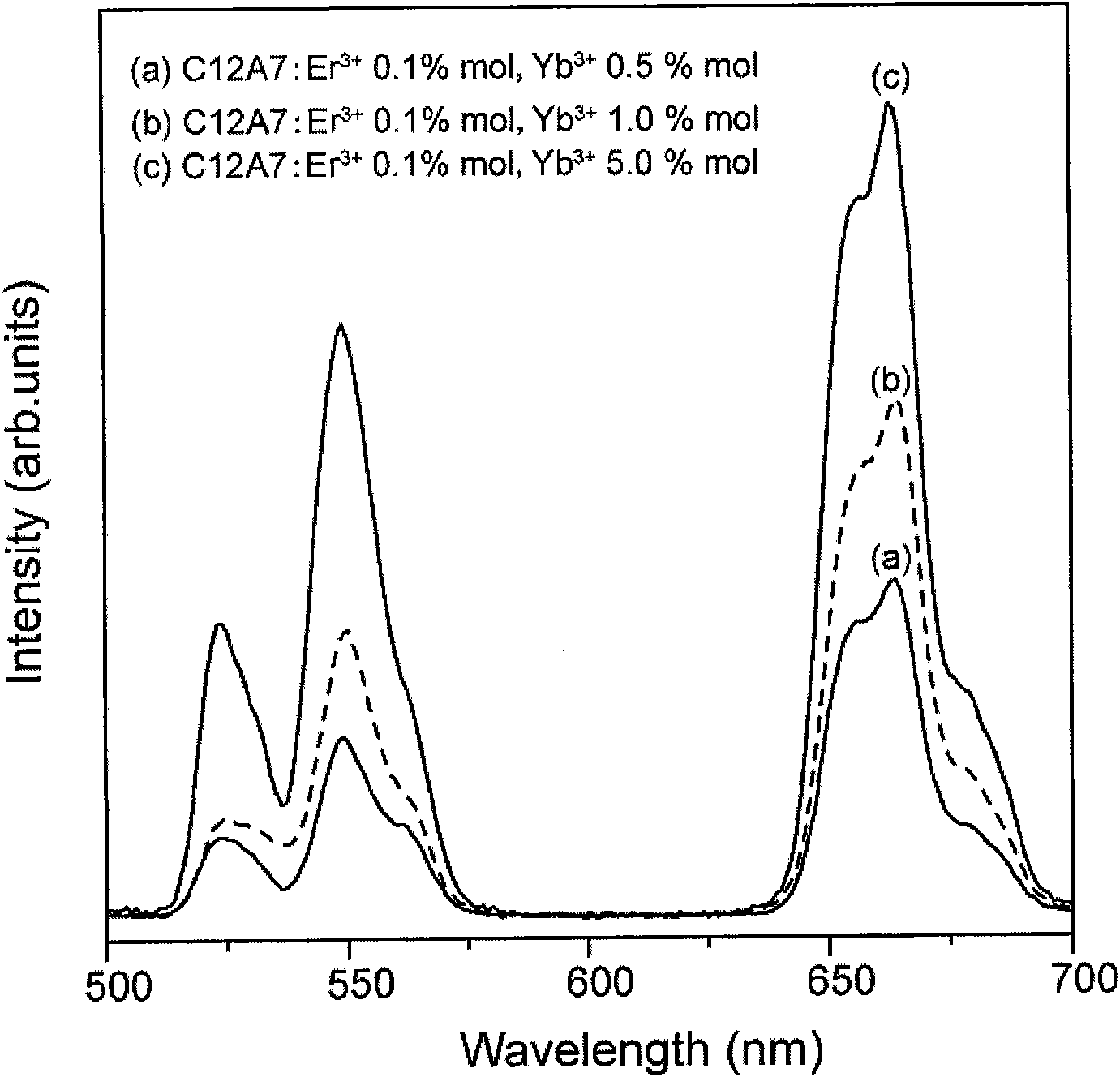

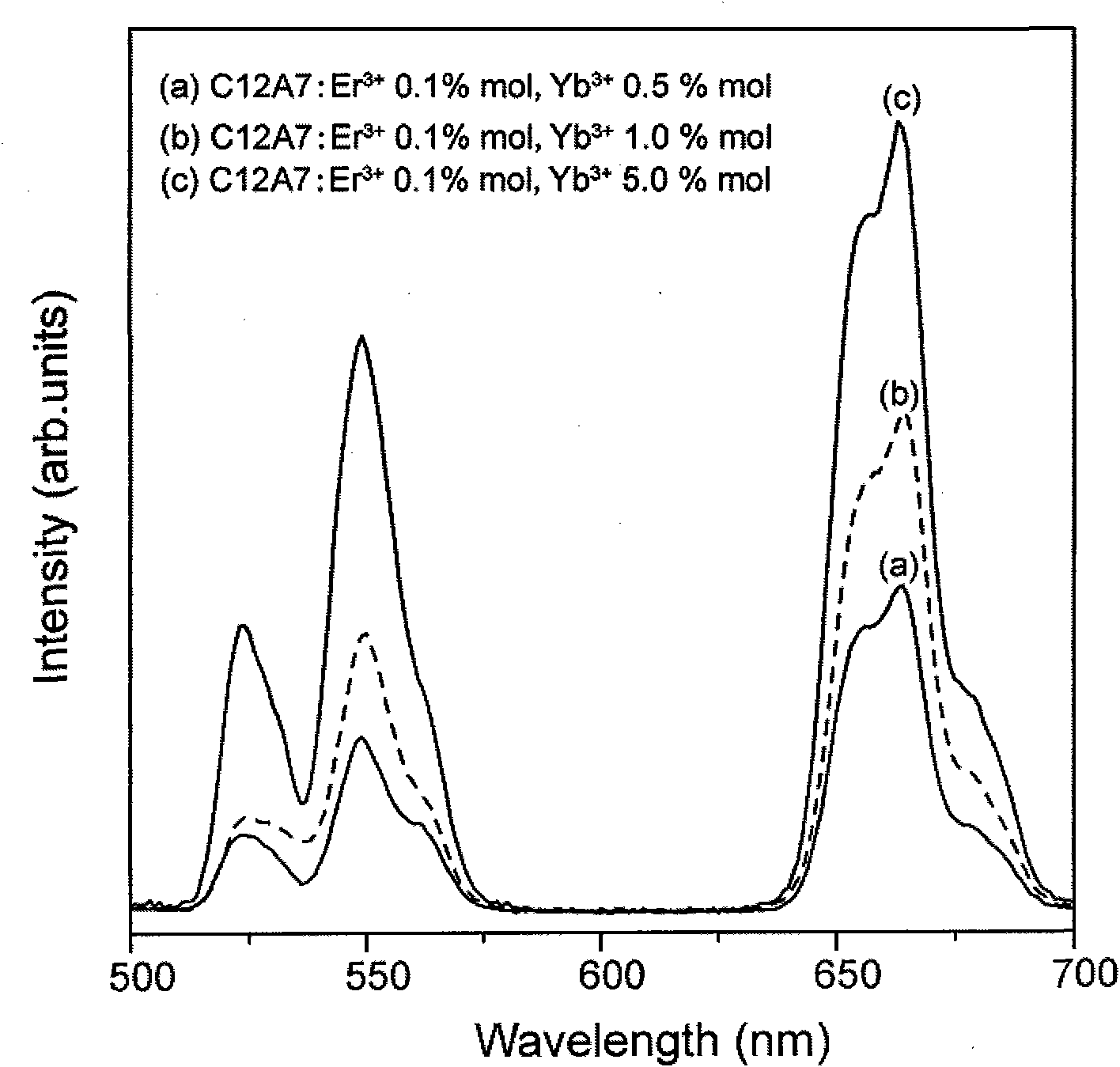

example 1

[0020] (1). Weighing 11.3629g of purity is 99.99% Al (NO 3 ) 3 9H 2 O, 6.1311g purity is 99.99% Ca (NO 3 ) 2 4H 2 O, 0.0093g of Er with a purity of 99.99% 2 o 3 , 0.2046g of Yb with a purity of 99.99% 2 o 3 Dissolve in deionized water, add 2ml of nitric acid dropwise, heat to 50°C and stir for 5 hours;

[0021] (2). Add dropwise 35ml of precipitant NH to the above solution 3 ·H 2 O, to obtain the gel precursor;

[0022] (3). Dry the obtained gel precursor at a temperature of 80°C to remove water;

[0023] (4). Put the dried gel in a high-temperature furnace, sinter at 1100°C for 6 hours in an air atmosphere, cool, and grind to obtain upconversion luminescence Er excited at 980nm 3+ / Yb 3+ Co-doped heptaaluminate dodecacalcium phosphor (12CaO 7Al 2 o 3 :Er 3+ 0.1% mol, Yb 3+ 0.5% mol).

example 2

[0025] (1). Weighing 18.9370g of purity is 99.99% Al (NO 3 ) 3 9H 2 O, 10.1159g purity is 99.99% Ca (NO 3 ) 2 4H 2 O, 0.0087g of Er with a purity of 99.99% 2 o 3 , 0.7673g of Yb with a purity of 99.99% 2 o 3 Dissolve in deionized water, add 4ml of nitric acid dropwise, heat to 30°C and stir for 8 hours;

[0026] (2). Add dropwise 60ml of precipitating agent NH to the above solution 3 ·H 2 O, to obtain the gel precursor;

[0027] (3). Dry the obtained gel precursor at a temperature of 100°C to remove water;

[0028] (4). Put the dried gel in a high-temperature furnace, sinter at 1090°C for 8 hours in an air atmosphere, cool, and grind to obtain upconversion luminescence Er excited at 980nm 3+ / Yb 3+ Co-doped heptaaluminate dodecacalcium phosphor (12CaO 7Al 2 o 3 :Er 3+ 0.1% mol, Yb 3+ 1.0% mol).

example 3

[0030] (1). Weighing 11.3622g of purity is 99.99% Al (NO 3 ) 3 9H 2 O, 5.8243g purity is 99.99% Ca (NO 3 ) 2 4H2 O, 0.0093g of Er with a purity of 99.99% 2 o 3 , 0.2506g of Yb with a purity of 99.99% 2 o 3 Dissolve in deionized water, add 10ml of nitric acid dropwise, heat to 70°C and stir for 2 hours;

[0031] (2). Add dropwise 110ml of precipitant NH to the above solution 3 ·H 2 O, to obtain the gel precursor;

[0032] (3). Dry the obtained gel precursor at a temperature of 90°C to remove water;

[0033] (4). Put the dried gel in a high-temperature furnace, sinter at 1180°C for 5 hours in an air atmosphere, cool, and grind to obtain upconversion luminescence Er excited at 980nm 3+ / Yb 3+ Co-doped heptaaluminate dodecacalcium phosphor (12CaO 7Al 2 o 3 :Er 3+ 0.1% mol, Yb 3+ 5.0% mol).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com