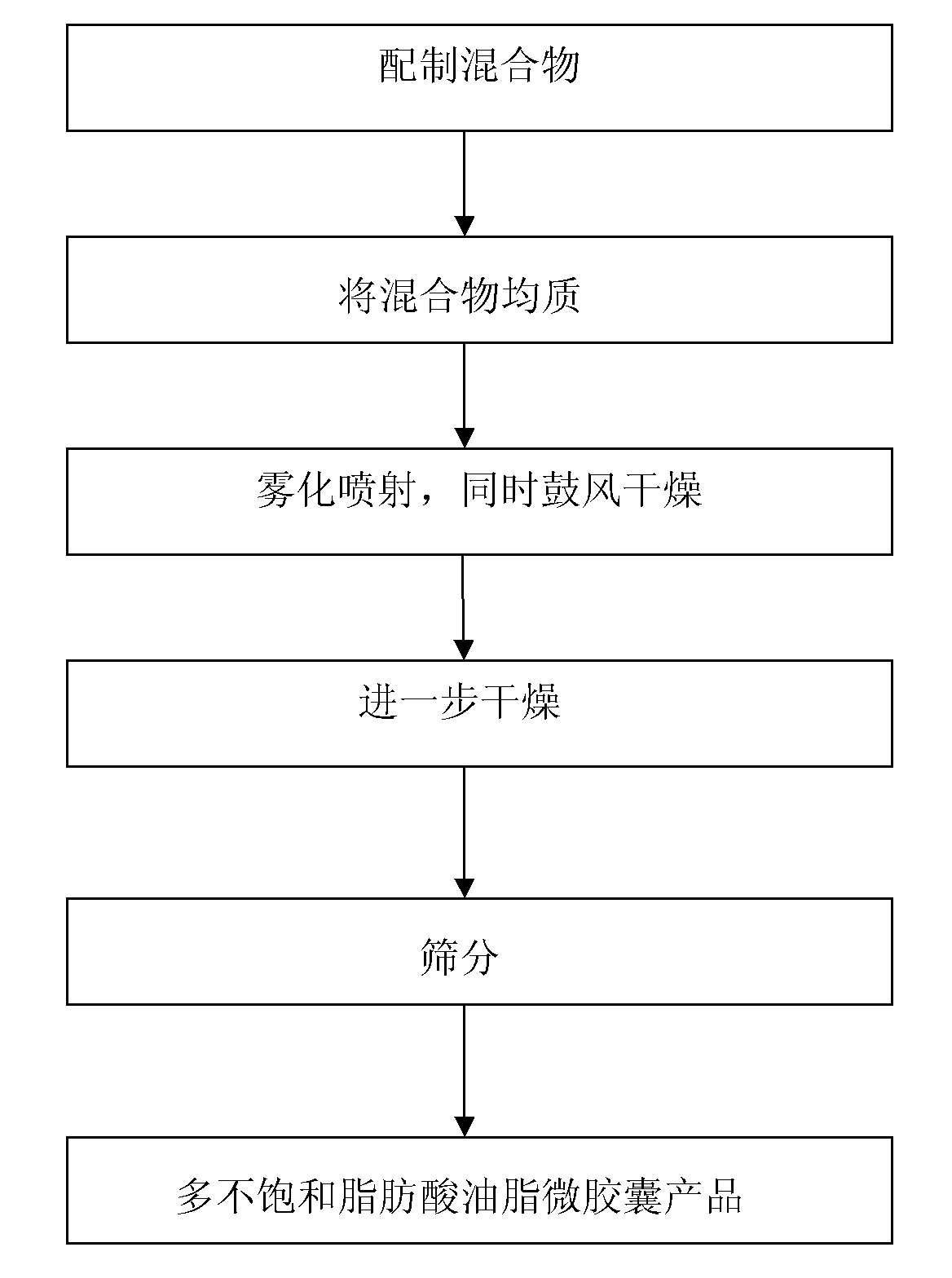

Preparation technology for polyunsaturated fatty acid oil microcapsule

An unsaturated fatty acid and preparation process technology, applied in the field of preparation of polyunsaturated fatty acid oil microcapsules, can solve the problems of easy inactivation of active ingredients, high temperature required for drying, easy gaps in the capsule wall, etc., and achieves good fluidity. , The effect of high oil embedding rate and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Table 1

[0023] Arachidonic acid content is

[0024] After mixing the ingredients described in Table 1 at 40°C, homogenize under a homogeneous pressure of 20 MPa to obtain a uniform emulsion; then use a high-pressure pump to atomize the emulsion into droplets through an atomizing spray gun and spray it into the preheated In the boiling drying device, the atomization pressure of the pressure atomization is 0.5MPa, the temperature in the boiling drying device is 90°C, 5000g of starch is installed at the bottom of the boiling drying device, and the temperature in the boiling drying device is maintained by blasting at the same time Not lower than 70°C, so that the atomized droplets are partially dried and wrapped by a layer of starch blown from the bottom, after the emulsion is completely sprayed into the boiling drying device; then increase the temperature of the boiling drying device to 80°C, Further dry for 3min, sieve, and separate the excess powder embedding...

Embodiment 2

[0029] Table 2

[0030] Arachidonic acid content is

[0031] After mixing the ingredients in Table 2 at 60°C, homogenize under a homogeneous pressure of 40MPa to obtain a uniform emulsion; then keep warm at 90°C for 3 minutes and sterilize; then use a high-pressure pump to pass the emulsion through an atomizing spray gun Atomized into droplets and sprayed into the preheated ebullient drying device. The atomization pressure of the pressure atomization is 2MPa, the temperature inside the ebullient drying device is 80°C, and 100Kg microcrystalline cellulose is installed at the bottom of the ebullient drying device. At the same time, air is blown to maintain the temperature in the boiling drying device not lower than 50°C, so that the atomized liquid droplets are partially dried and wrapped by a layer of microcrystalline cellulose blown from the bottom. At the same time, vacuum feeding equipment is used to continuously Supplement 600kg of microcrystalline cellulose into ...

Embodiment 3

[0036] table 3

[0037] Docosahexaenoic acid contains

[0038] After mixing the ingredients described in Table 3 at 80°C, homogenize under a homogeneous pressure of 60MPa to obtain a uniform emulsion; then keep warm at 90°C for 3 minutes and sterilize; then send the emulsion into the boiling drying device through a delivery pump In the centrifugal disc above, the emulsion is atomized into droplets under the high-speed centrifugal action of the centrifugal disc and dispersed into the preheated boiling drying device. The centrifugal disc rotating speed of the centrifugal atomization is 2000-3500r / min , the temperature in the boiling drying device is 90°C, 100Kg of tricalcium phosphate is installed at the bottom of the boiling drying device, and at the same time blowing air is used to maintain the temperature in the boiling drying device not lower than 50°C, so that the atomized droplets are partially dried, And it is wrapped by the tricalcium phosphate blown from the b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com