Synchronous nitrogen and phosphorus removal process of integral bio-enhancement activated carbon dynamic membrane

A simultaneous nitrogen and phosphorus removal and bioaugmentation technology, which is applied in the field of synchronous nitrogen and phosphorus removal technology with integrated bio-enhanced activated carbon dynamic membrane, can solve the problem of slow value-added speed of nitrifying bacteria, increased processing costs, increased power consumption and operating costs, etc. problems, to achieve the effect of increasing microbial biomass and microbial activity, reducing energy consumption and operating costs, and having a high degree of automatic control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

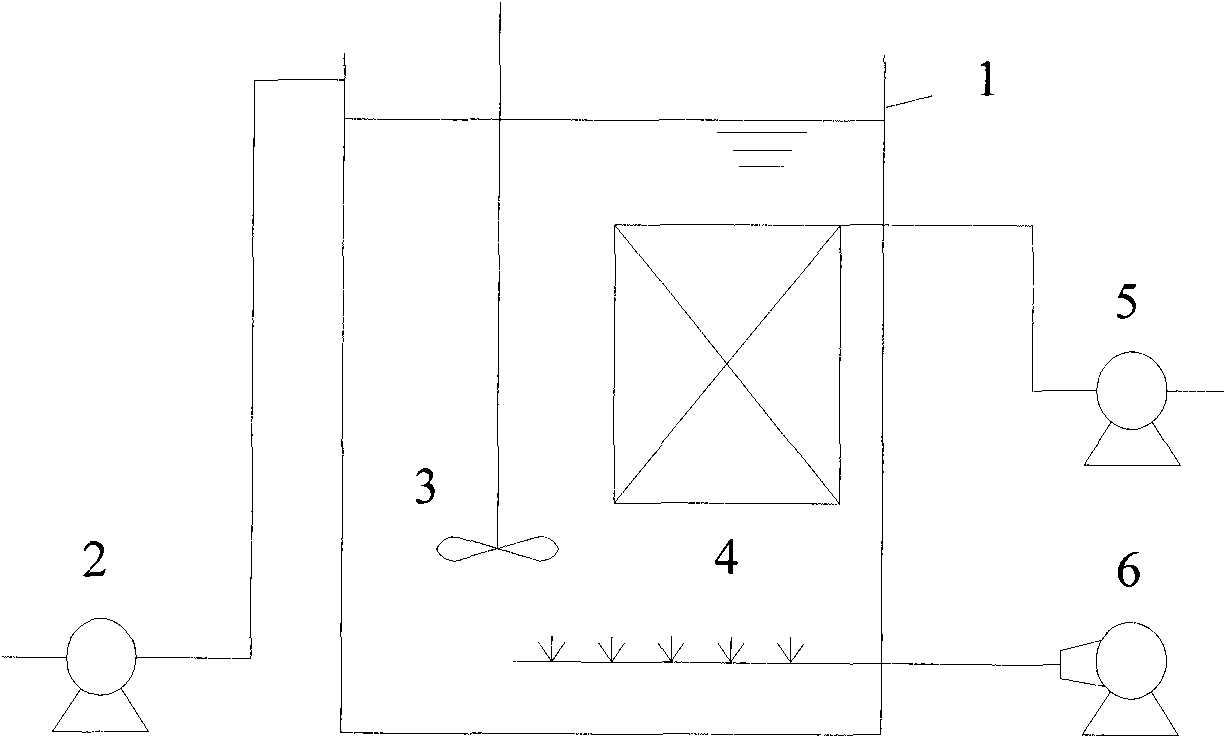

Image

Examples

Embodiment 1

[0034] The physical and chemical properties of powdered activated carbon used in the implementation process are shown in Table 1. The inoculated sludge (MLSS is 5000mg / L) and the raw sewage used in the experiment (see Table 2 for water quality) were all taken from a municipal sewage treatment plant in Shanghai.

[0035] Table 1 Physical indicators of powdered activated carbon

[0036] iodine value

>900mg / g

Adsorption value of methylene blue

≥120mg / g

specific surface area

>1000m 2 / g

≤8%

PH value

5-7

Diameter (microns)

40-80

[0037] Table 2 Raw water quality

[0038] COD Cr (mg / L)

150-350

NH 4 -N (mg / L)

20-30

TN (mg / L)

20-40

SS(mg / L)

30-380

TP (mg / L)

1.5-4.5

pH

6.5-7.5

[0039] (1) Bioenhanced activated carbon cultivation

[0040] During the start-up stage of the device, powdered activated carbon with an average particle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com