Composite extraction method for extracting coumarin from radix angelicae dahuricae

A coumarin and extraction technology, applied in the production of bulk chemicals, organic chemistry, etc., can solve the problems of high production cost, difficult industrial application, complex process, etc., to avoid decomposition, low operating temperature, and simple operation process. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

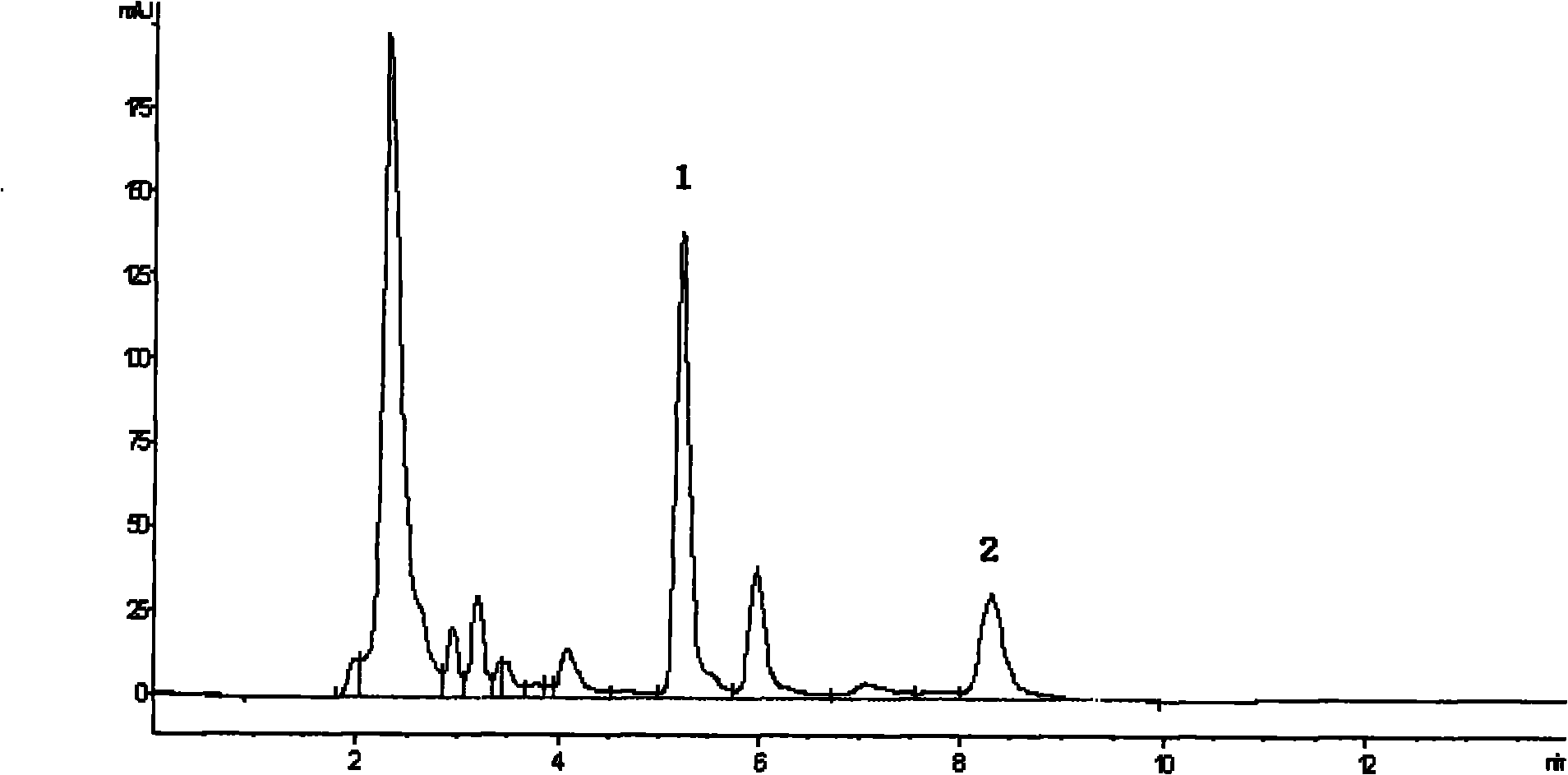

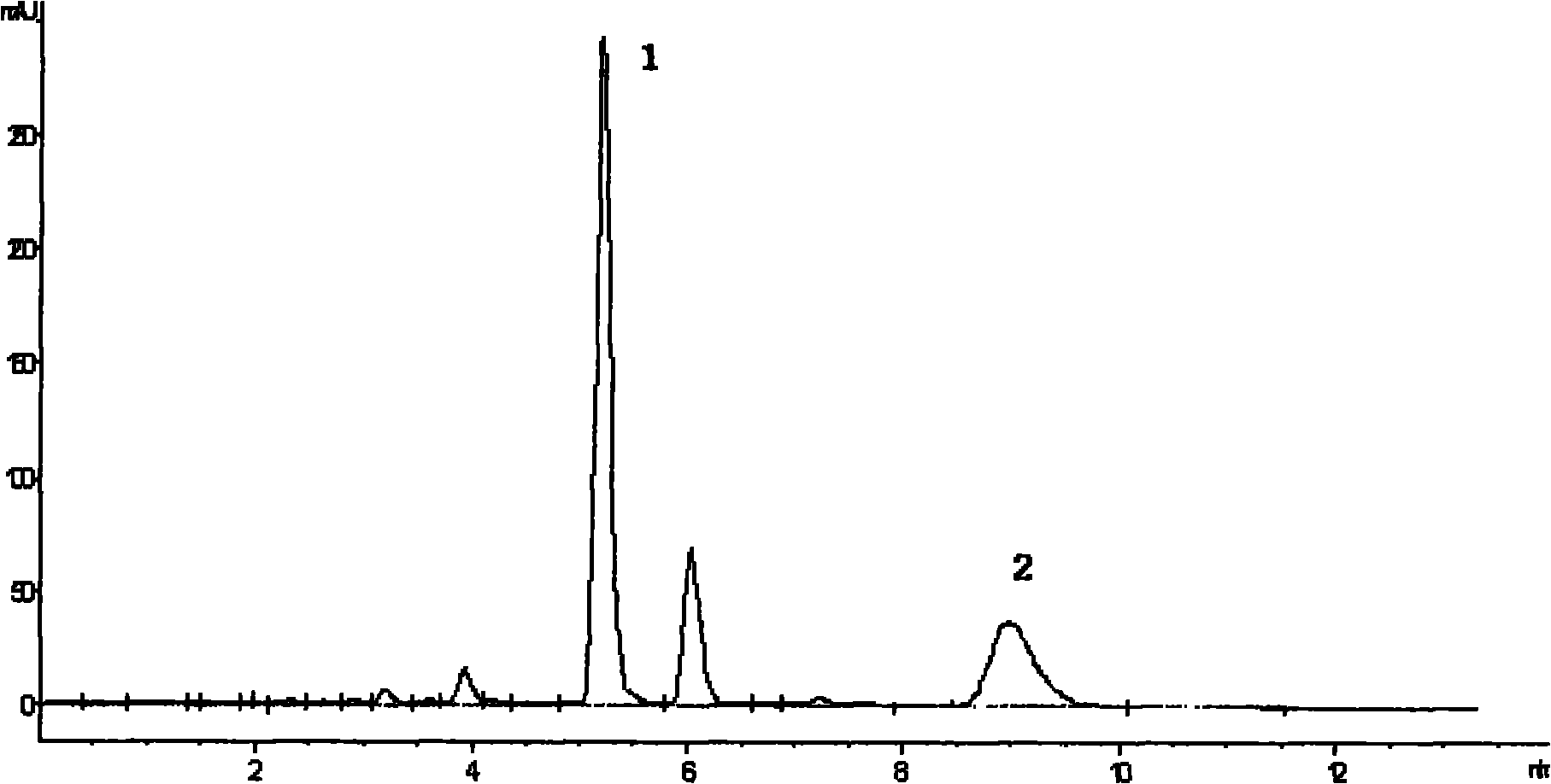

[0022] ③ Preparation of reference solution

[0023] Accurately weigh 5.43 mg of imperatorin reference substance and 6.09 mg of isoimperatorin, respectively, and place them in 25 mL volumetric flasks, dilute with methanol to the mark, and shake well. Accurately take 2mL respectively, place in a 10mL volumetric flask, dilute with methanol to the mark, and shake well to obtain a mixed reference solution of imperatorin 43.44 μg / mL and isoimperatorin 48.72 μg / mL.

[0024] ④ Preparation of standard curve:

[0025] Take the above-mentioned mixed reference substance solution, inject samples with different volumes of 5 μL-30 μL according to the chromatographic conditions, take the injection volume (μL) as the abscissa, and the peak area as the ordinate regression, and the equation is: imperatorin y=157.29x- 6.3333 (r=1), the measurement result has a good linear relationship within 0.2172 μg-1.3032 μg; isoimperatorin y=152.52x-30.833 (r=1), the measurement result has a good linear rela...

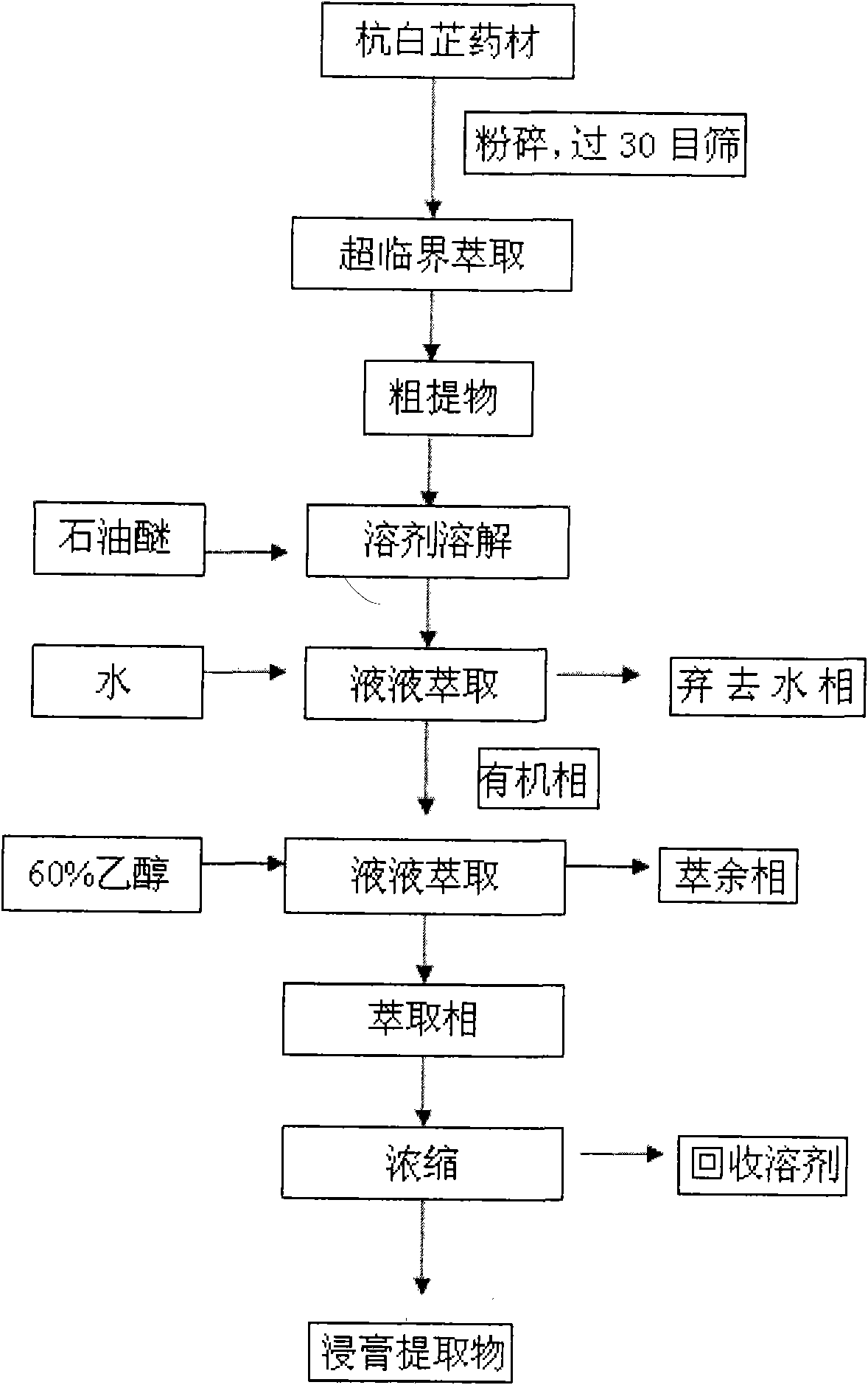

Embodiment 1

[0031] Take by weighing 1kg and pulverize to 30 orders, the coumarin content is 0.1% the raw material of Angelica dahuricae, put into 5 liters of supercritical extractors. Set the extraction temperature and pressure to 40°C and 30MPa, respectively, and the separation temperature and pressure to 35°C and 5MPa, respectively. 2 After 2 hours of extraction, 5.142 g of extract was obtained. Add 52mL of petroleum ether (boiling range 60-90°C, the same below) at a weight-to-volume ratio of 1:10 to dissolve the extract completely. Then it was extracted twice with 3 times the volume of petroleum ether, and the aqueous layer was discarded. The petroleum ether layer was extracted three times with 60% ethanol at a volume ratio of 1:2.5, the ethanol solution was collected, concentrated under reduced pressure to remove the solvent, and 0.232 g of the product was obtained. Through liquid chromatography analysis, the obtained product contains 39.72% coumarin active ingredients. Among them,...

Embodiment 2

[0033] Weigh 1 kg of Baizhi raw material and crush it to 30 mesh, put it into a 5-liter extractor, the extraction temperature and pressure are 50°C and 25MPa, the separation temperature and pressure are 35°C and 6MPa, respectively, after 2 hours of extraction, 5.156g of extract product. The product was dissolved in 52 mL of petroleum ether, extracted three times with 130 mL of water, and the aqueous phase was discarded. The petroleum ether phase was extracted 4 times with 2.5 volumes of 60% ethanol. The ethanol solvent was collected and concentrated to dryness under reduced pressure to obtain 0.228 g of the product with a total coumarin content of 40.57%. Among them, the content of imperatorin is 24.68%, the content of isoimperatorin is 15.89%

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com