Bulk silicon micro mechanic resonator and manufacturing method thereof

A silicon micromachine and silicon resonator technology, applied in resonator, microstructure technology, waveguide-type devices, etc., can solve the problems of high complexity and difficult processing technology, so as to reduce the production cost, reduce the process complexity, improve the effect on device performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

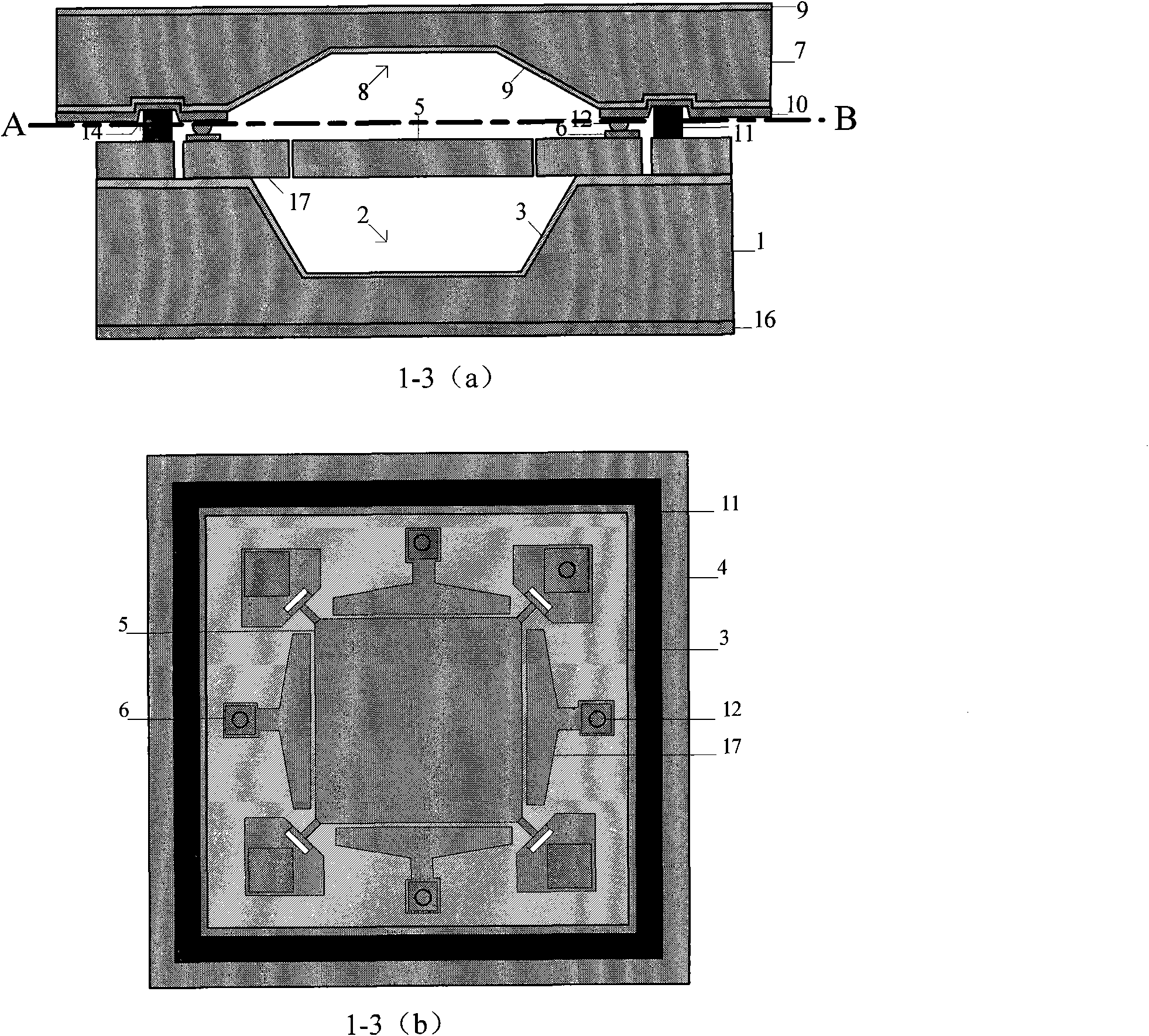

[0091] A layer of TiW / Au metal layer is deposited on both the resonator structure wafer and the cover plate wafer, and the metal layer on the structure wafer and the cover plate wafer is patterned by photolithography and etching. A layer of adhesive (adhesive can be glass paste, polymer or metal) is coated on the back of the silicon wafer by screen printing, and the adhesive is patterned, and the adhesive is used as a solder layer. The resonator device is electrically connected to the external circuit through the metal layer. The resistivity range of the substrate silicon wafer and the structural silicon wafer is 0.01-0.3Ω·cm, and the resistivity of the cover silicon wafer is not required, which is an ordinary silicon wafer. The main process steps include:

[0092] (1) On the polished heavily doped single crystal silicon wafer, the bottom cavity for the release of the resonator structure is fabricated by oxidation, photolithography, and silicon anisotropic wet etching process...

Embodiment 2

[0106] The cover plate silicon wafer is made of lightly doped N-type silicon wafer, and the P+ region is formed on the cover plate silicon wafer through methods such as oxidation, gluing photolithography, silicon oxide corrosion, and ion implantation. A layer of TiW / Au metal layer is deposited on both the resonator structure wafer and the cover plate wafer, and the metal layer on the structure wafer and the cover plate wafer is patterned by photolithography and etching. A layer of adhesive (adhesive can be glass paste, polymer or metal) is coated on the back of the silicon wafer by screen printing, and the adhesive is patterned, and the adhesive is used as a solder layer. The resonator device is electrically connected to the external circuit through the P+ region. The resistivity range of the substrate silicon wafer and the structural silicon wafer is 0.01-0.3Ω·cm, and the resistivity range of the cover silicon wafer is 0.01-1Ω·cm. The main process steps include:

[0107] (1...

Embodiment 3

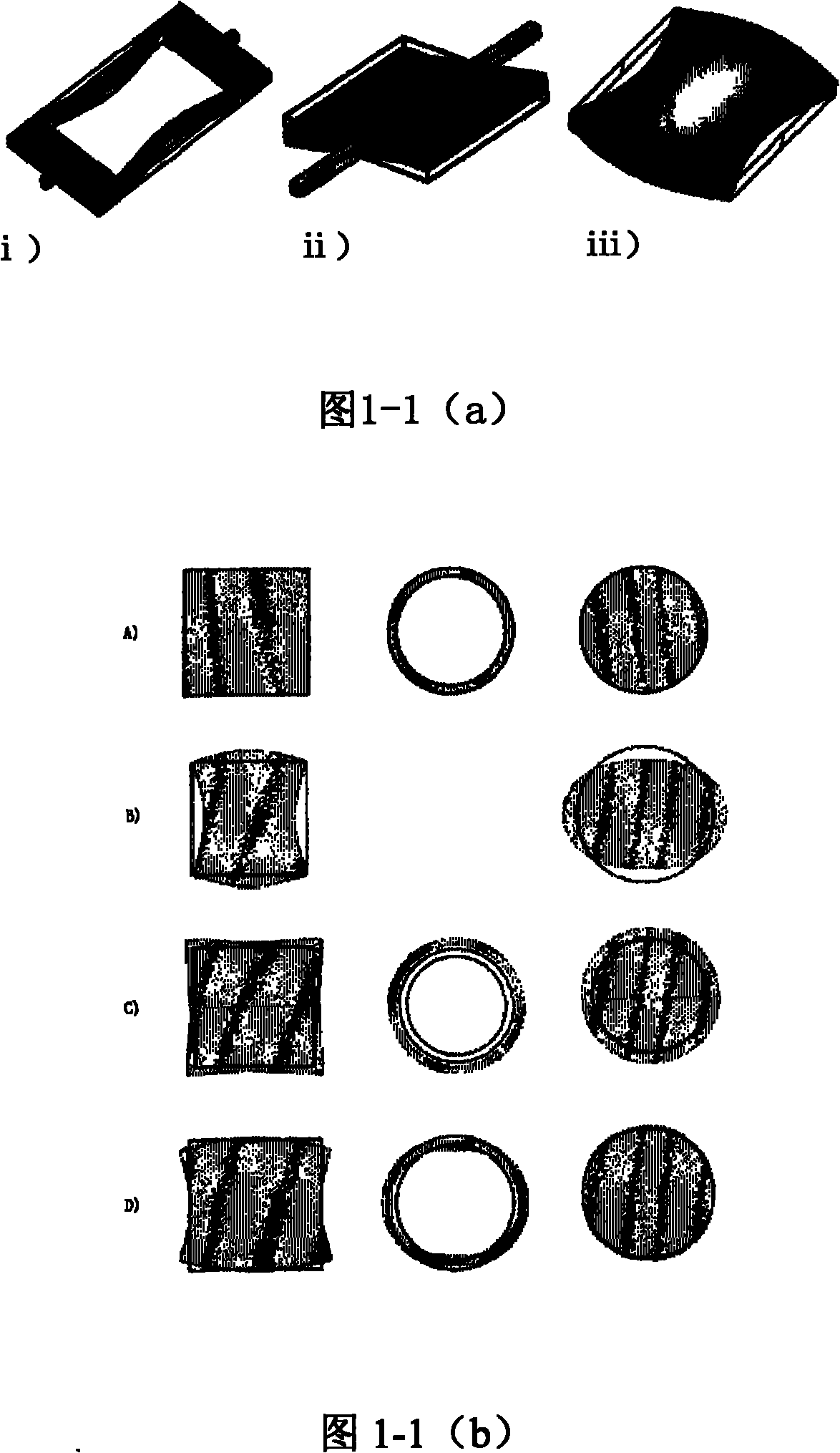

[0122] The substrate silicon wafer and structural silicon wafer of the bulk silicon resonator adopt low-resistance silicon wafers, the resistivity range of the substrate silicon wafer and structural silicon wafer is 0.01-0.3Ω·cm, and the cover silicon wafer is an ordinary silicon wafer. In order to enhance the strength of the driving signal and the detection signal, and further improve the performance of the resonator, the resonant oscillators of the two bulk silicon micromechanical resonators can be connected together through a beam coupling. Its specific embodiment is identical with embodiment 1. The main differences are: (1) different resonator oscillators: the oscillator of the resonator in embodiment 1 is a square plate, and the oscillator of the resonator in this embodiment is a figure in which two square plates are connected by a beam, see Figure 1-5 (a); (2) Different driving electrodes: the resonator in embodiment 1 has four electrodes symmetrically distributed around...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com