Method for ozonizing phenol wastewater by taking ceramic powder material as catalyst

A technology of ceramic powder and ozonated water, which is applied in the field of environmental protection and environmental catalysis, to achieve the effect of accelerating the degradation rate and improving the degree of mineralization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

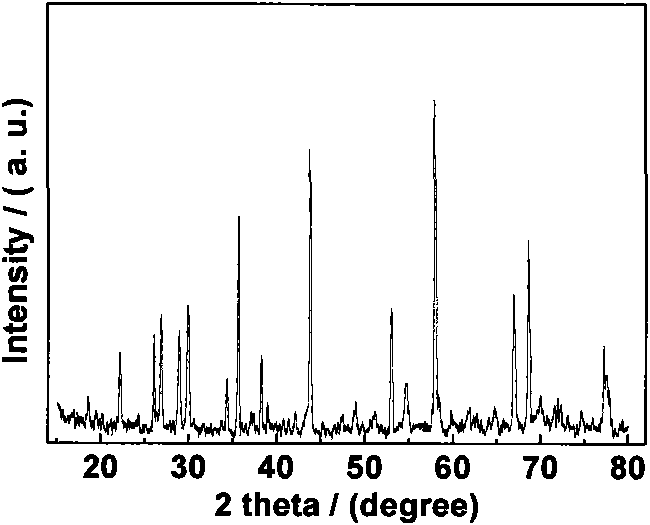

[0023] The formed ordinary honeycomb ceramics are sieved (100 mesh) after knocking and ball milling to obtain ceramic powder materials. The XRD diffraction results are shown in figure 1 , through nitrogen low-temperature adsorption-desorption isotherm, the BET specific surface area of the ceramic powder is 1.30m 2 g -1 . The surface hydroxyl density of the ceramic powder material obtained by chemical titration is 1.63×10 -5 mole g -1 . The pH of the ceramic powder was determined experimentally pzc is 6.52.

Embodiment 2

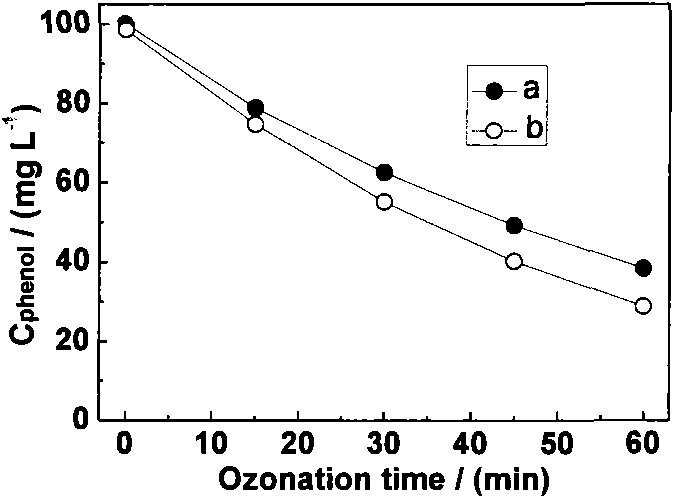

[0025] The initial concentration of phenol in 200ml is 100mg L -1 In the simulated wastewater, add 1.0g of ceramic powder material, start stirring, and pass through the ozone flow rate of 0.40mg min at the reaction temperature of 20°C -1 Ozone, record the concentration of phenol at different times. The result is as figure 2 As shown, line a is ozonation alone (no catalyst), and line b is ozonation catalyzed by ceramic powder materials. It indicated that the addition of nano-zinc oxide significantly promoted the degradation of phenol.

Embodiment 3

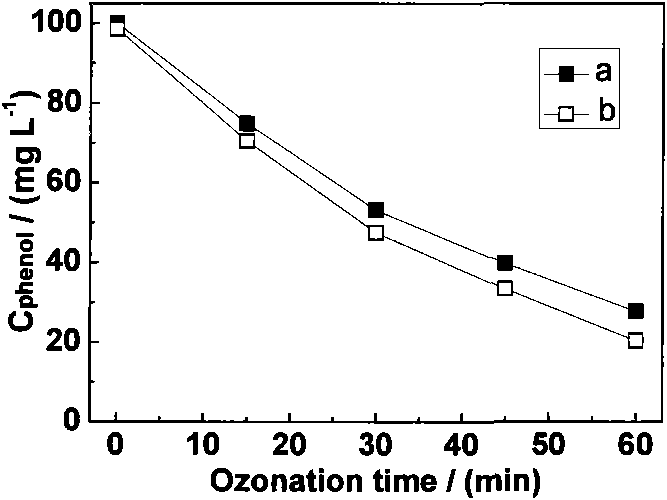

[0027] The initial concentration of phenol in 200ml is 100mg L -1 In the simulated wastewater, add 1.0g of ceramic powder material, start stirring, and pass through the ozone flow rate of 0.40mg min at the reaction temperature of 20°C -1 Ozone, record the concentration of phenol at different times. The result is as image 3 As shown, line a is ozonation alone (no catalyst), and line b is ozonation catalyzed by ceramic powder materials. It indicated that the addition of nano-zinc oxide significantly promoted the degradation of phenol.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com