Nitrogen and phosphorus removal bio-trickling filter by artificially strengthening natural ventilation

A biological trickling filter and natural ventilation technology, applied in the field of environmental protection, can solve the problems of inconspicuous aerobic, anoxic and anaerobic environments, and the difficulty of obtaining steel slag fillers, etc., to achieve improved oxygen supply effect, simple structure, and low cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with the accompanying drawings.

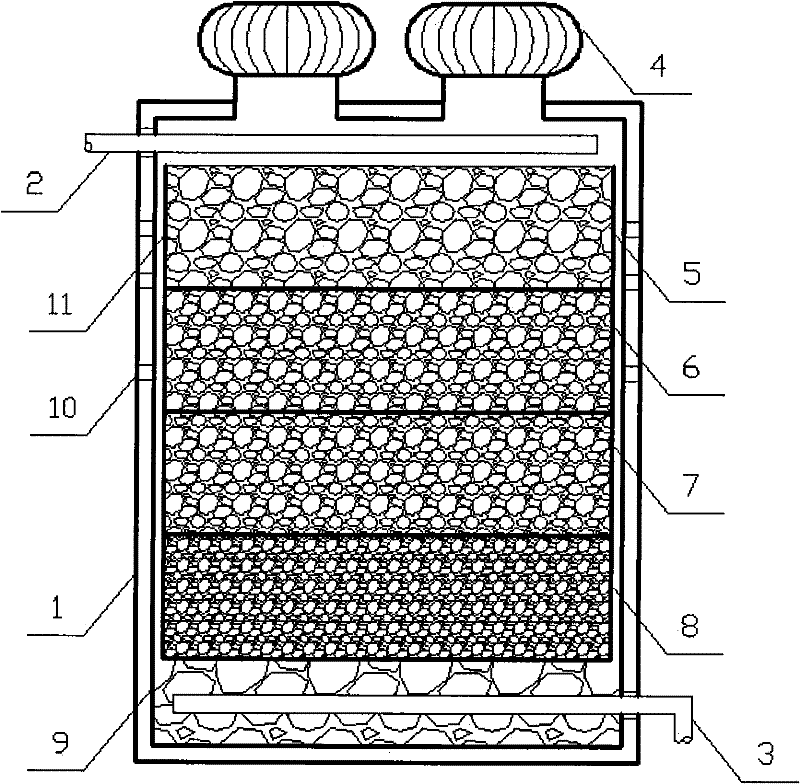

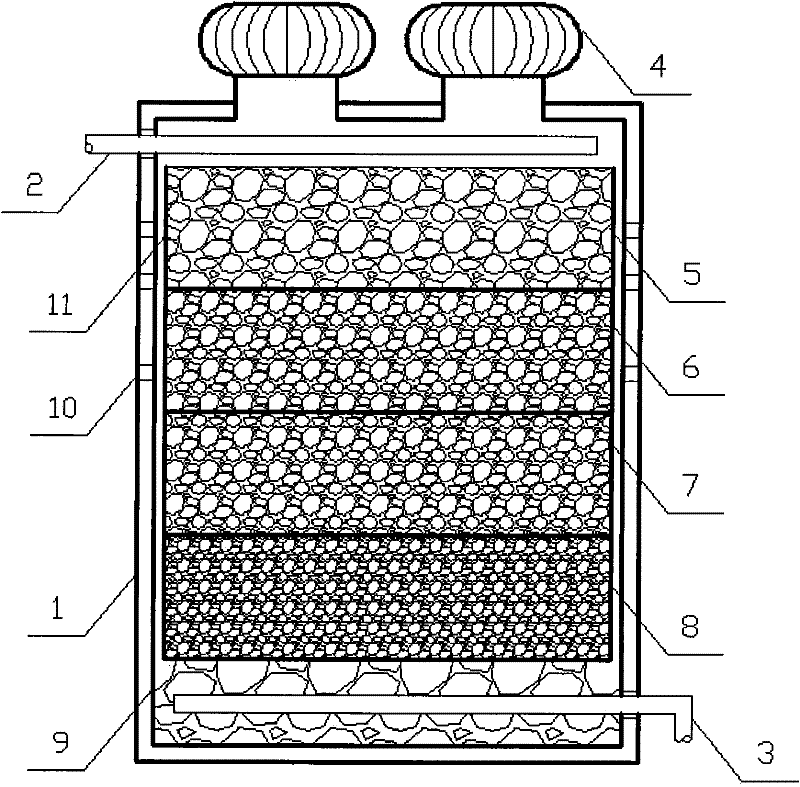

[0018] In the embodiment shown in the drawings, it can be seen that the top of the biological trickling filter body 1 is provided with a non-powered ventilation device 4, and the top is sealed except for the opening of the non-powered ventilation device 4. The unpowered ventilation device 4 relies on the wind force of any wind direction and the temperature difference between the inside of the pool body 1 and the outside of the pool body 1 to ventilate the filter. The filter material is filled in the grid frame 11 in layers, and is divided into four layers from top to bottom. There are ventilation holes on the pool walls of the aerobic zone 5 and the facultative oxygen zone 6. According to different oxygen supply requirements, the number of ventilation holes in the aerobic zone 5 is more than that of the facultative oxygen zone 6. The particle size of the filter materi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com