Device for culturing microalgae

A technology of microalgae and algae liquid, applied in enzymology/microbiology devices, biochemical cleaning devices, microorganism-based methods, etc., can solve the problem of high investment cost and operating cost, difficult to control operating parameters, and unfavorable large-scale production. and other problems, to achieve the effect of reducing the cost of recovery and treatment, increasing the contact area of gas and liquid, and solving the accumulation of dissolved oxygen

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] This example illustrates a microalgae cultivation device and cultivation method on a scale of 1 ton of algae liquid.

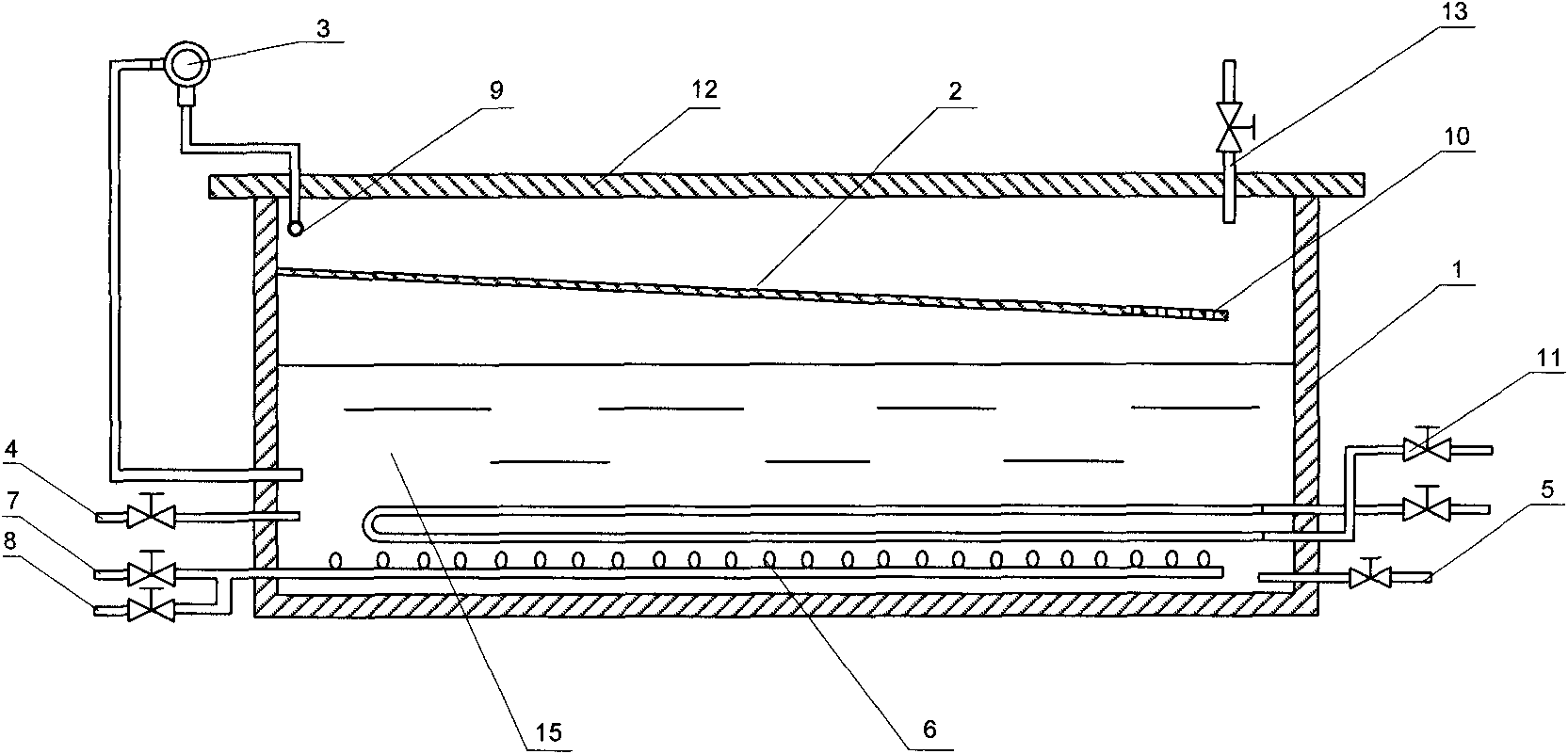

[0051] Such as figure 1 The microalgae culture device shown. The algae liquid storage unit 1 is a box made of transparent glass, with a length of 3000mm, a width of 500mm, and a height of 1000mm. The four sides of the algae liquid storage unit 1 are pasted with a plastic film with a light transmittance of 50%. Face 12 is transparent glass. The algae liquid diversion surface 2 is transparent glass with a plastic film with a light transmittance of 50%, which divides the algae liquid storage unit into two areas, the upper bright (light area) and the lower dark (dark area). The height of one end of the surface 2 is 800mm, and the height of the other end is 700mm, and there are grooves and screen holes 10 for the algae liquid to flow down. The algae liquid delivery device 3 is a diaphragm pump. Aeration device 6 is installed at the bottom of the algae liqu...

Embodiment 2

[0054] This example illustrates a microalgae cultivation device and cultivation method on a scale of 10 t of algae liquid.

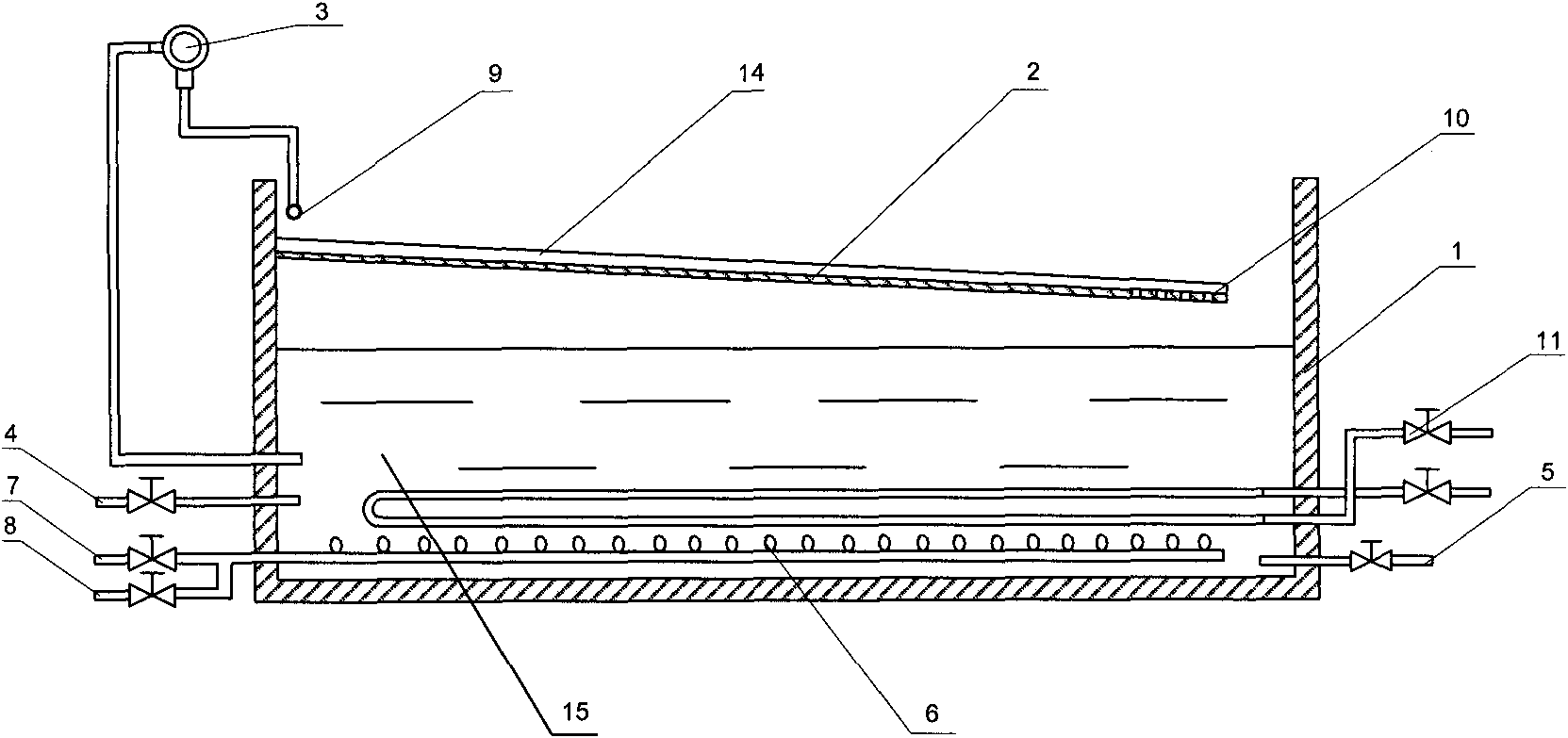

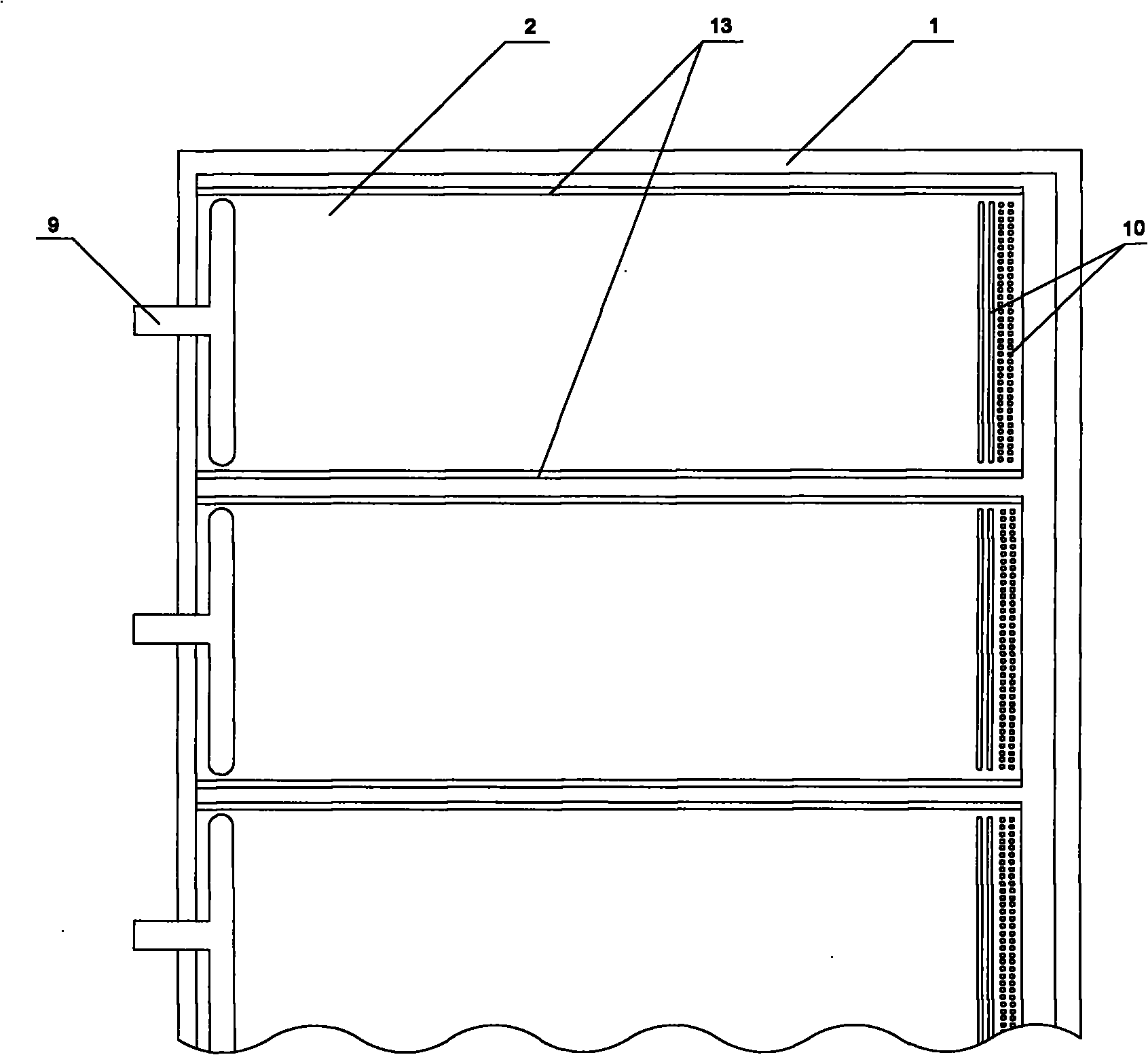

[0055] Such as figure 2 In the microalgae breeding device shown, the algae liquid storage unit is a box with an open top, which is made of reinforced concrete structure and is waterproofed. It is 3m long, 5m wide, and 1m high. Flow Noodles 2 ( image 3 Not all are marked in the middle), and the algae liquid storage unit is divided into upper bright (light area) and lower dark (dark area) two regions, and the algae liquid diversion surface 2 is a plastic film with a light transmittance of 50%. The algae liquid conveying equipment 3 is a diaphragm pump, and the algae liquid diversion surface 2 is located at one end of the algal liquid outlet of the algae liquid conveying device 3. The height is 800mm, and the height at the other end is 700mm. Sieve hole 10, aeration device 6 is installed at the bottom of the algae liquid storage unit for air and CO 2 A...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com