Side part reinforcing layer and run-flat tire

A runflat and reinforcing layer technology, which is applied in the direction of special tires, tire parts, reinforcing layers of pneumatic tires, etc., can solve the problems of insufficient load support and low hardness, so as to improve control stability and prevent air leakage Excellent durability and lightweight effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~2 and comparative example 1~2

[0109]

[0110] According to the formulation in Table 1, a masterbatch containing polyparaphenylene terephthalamide (PPTA) and stearic acid was prepared.

[0111] [Table 1]

[0112]

quality%

50

A silane coupling agent (Note 2)

6

Vulcanization accelerator (Note 3)

0.3

Sulfur (Note 4)

0.1

Stearic acid (Note 5)

42

[0113] (Note 1) Polyparaphenylene terephthalamide (PPTA): "Twaron" manufactured by Teijin.

[0114] (Note 2) Silane coupling agent: "Si69" manufactured by Dyssa Corporation.

[0115] (Note 3) Vulcanization accelerator: "NS" manufactured by Ouchi Shinko Chemical Industry Co., Ltd.

[0116] (Note 4) Sulfur: "Shiyu-ClonOT" manufactured by Shikoku Chemical Industry Co., Ltd.

[0117] (Note 5) Stearic acid: "Tsubaki" manufactured by NOF Corporation.

[0118]

[0119] According to the compounding content shown in Table 2, using a Banbury mixer, the insoluble sulfur and components other than the vulcanization accelerator were kneade...

Embodiment 3~7、 comparative example 3~7

[0147] Using the side reinforcement layers of the combination 1 and the combination 3 used in Example 1, Comparative Example 1, in the same manner as in Example 1, a run-flat tire with the material and structure of the carcass ply changed was manufactured.

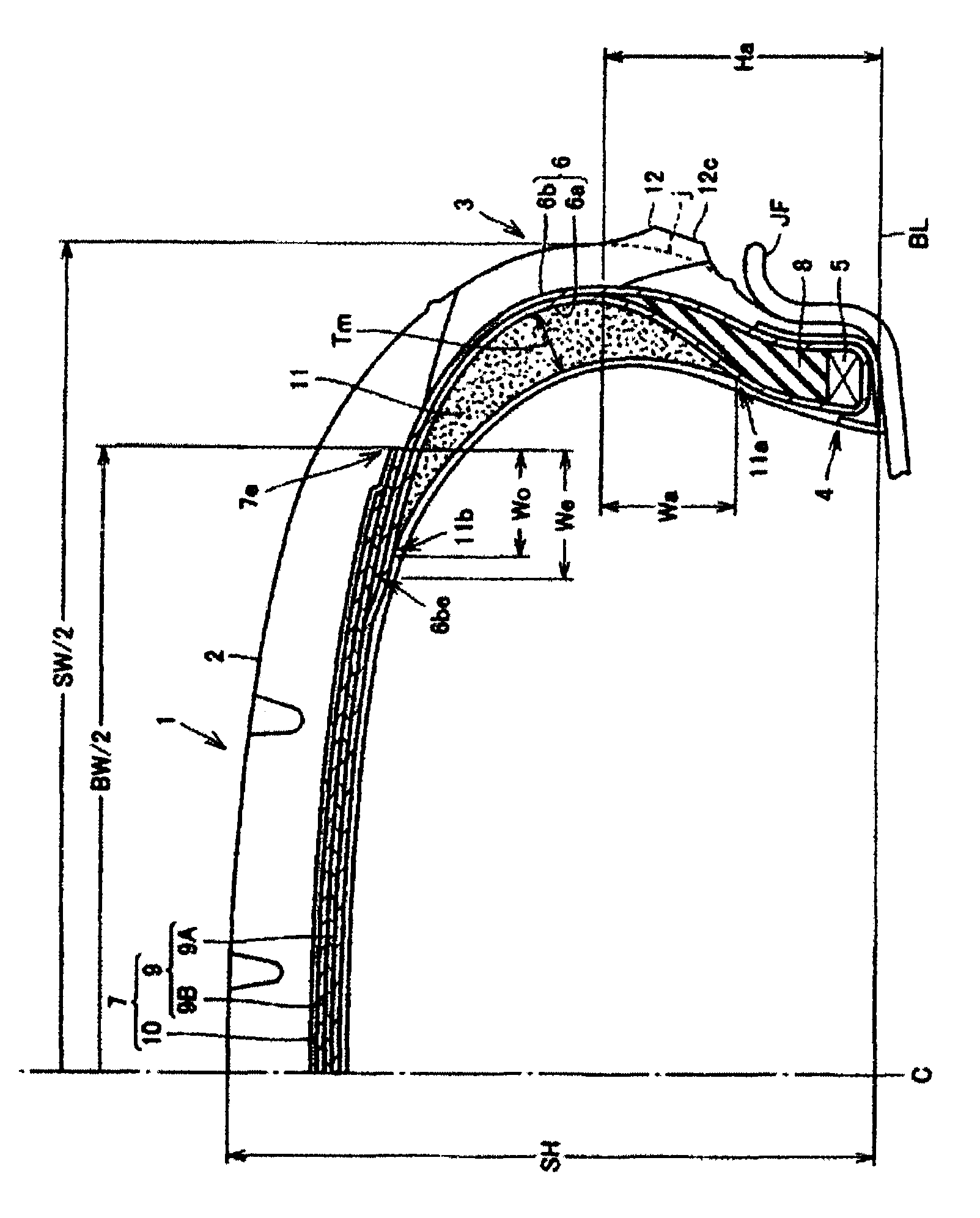

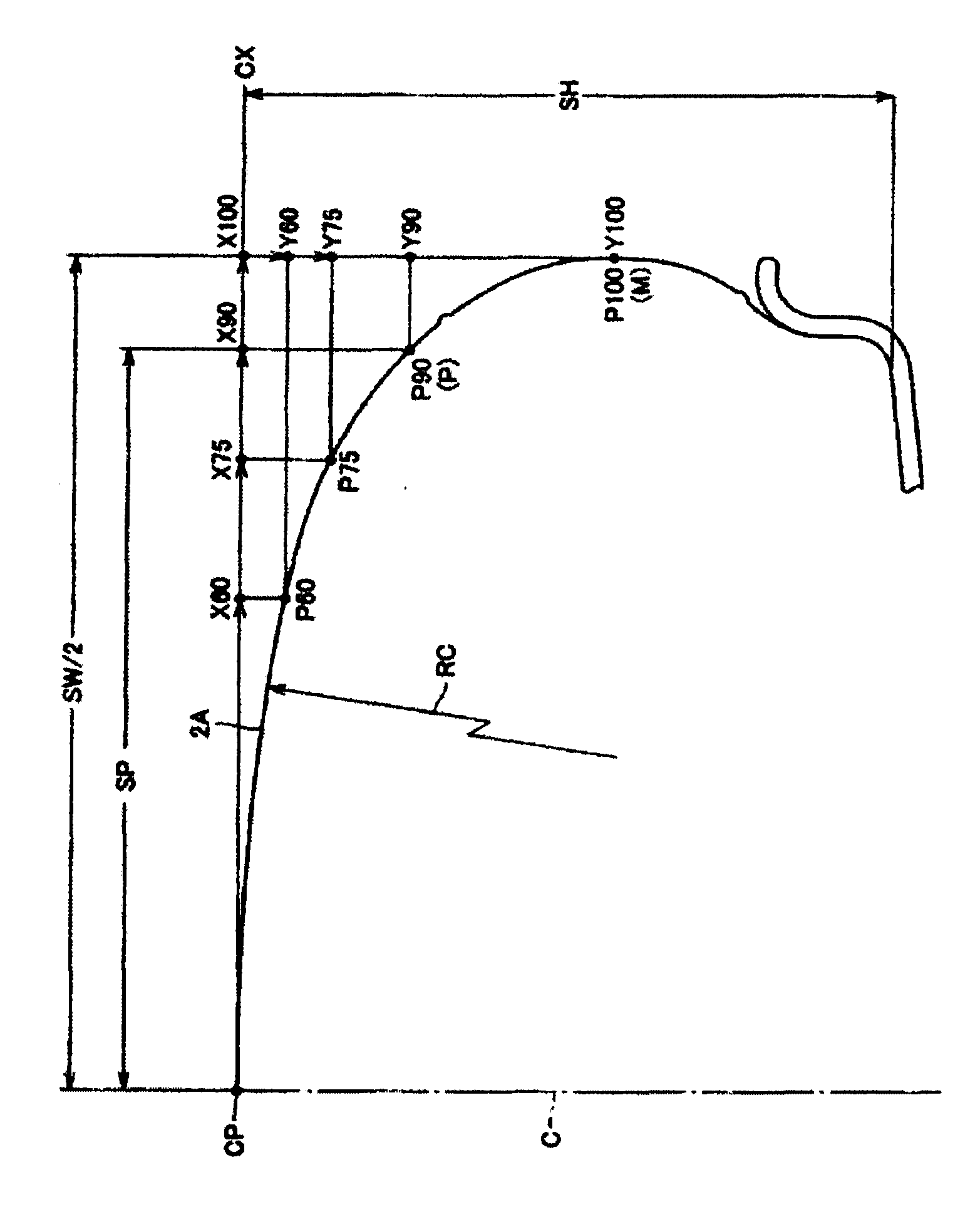

[0148] Here, the basic structure of a run flat tire is figure 1 As shown, except for the material and structure of the carcass shown in Table 3, the same method is adopted. The basic way is as follows.

[0149] Carcass: 1 ply, the cord angle is 90° with respect to the circumferential direction.

[0150] Belt layer: Two belt plies of steel cords are laminated in opposite directions at a cord angle of 24° with respect to the tire circumferential direction.

[0151] Side reinforcement layer: the maximum thickness of rubber is 10.0mm.

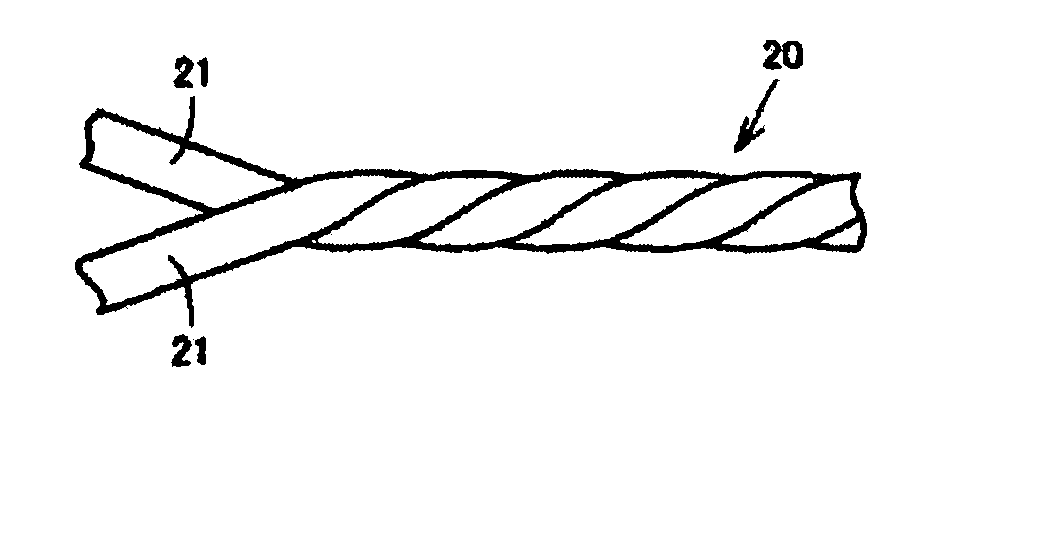

[0152] In Table 3, the twist coefficient T is represented by the following formula (1).

[0153]

[0154] In addition, the specific gravity ρ of the rayon fiber cord was 1.51, and the specific gravity ρ ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elastic modulus | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com