Semiconductor device with heat radiation and gain

A semiconductor and conductor chip technology, which is applied in semiconductor devices, semiconductor/solid-state device components, electric solid-state devices, etc., can solve problems such as labor-intensive, time-consuming and labor-intensive, laser drilling costs and time, etc., to improve design freedom The effect of high temperature, stable placement, and good heat dissipation structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

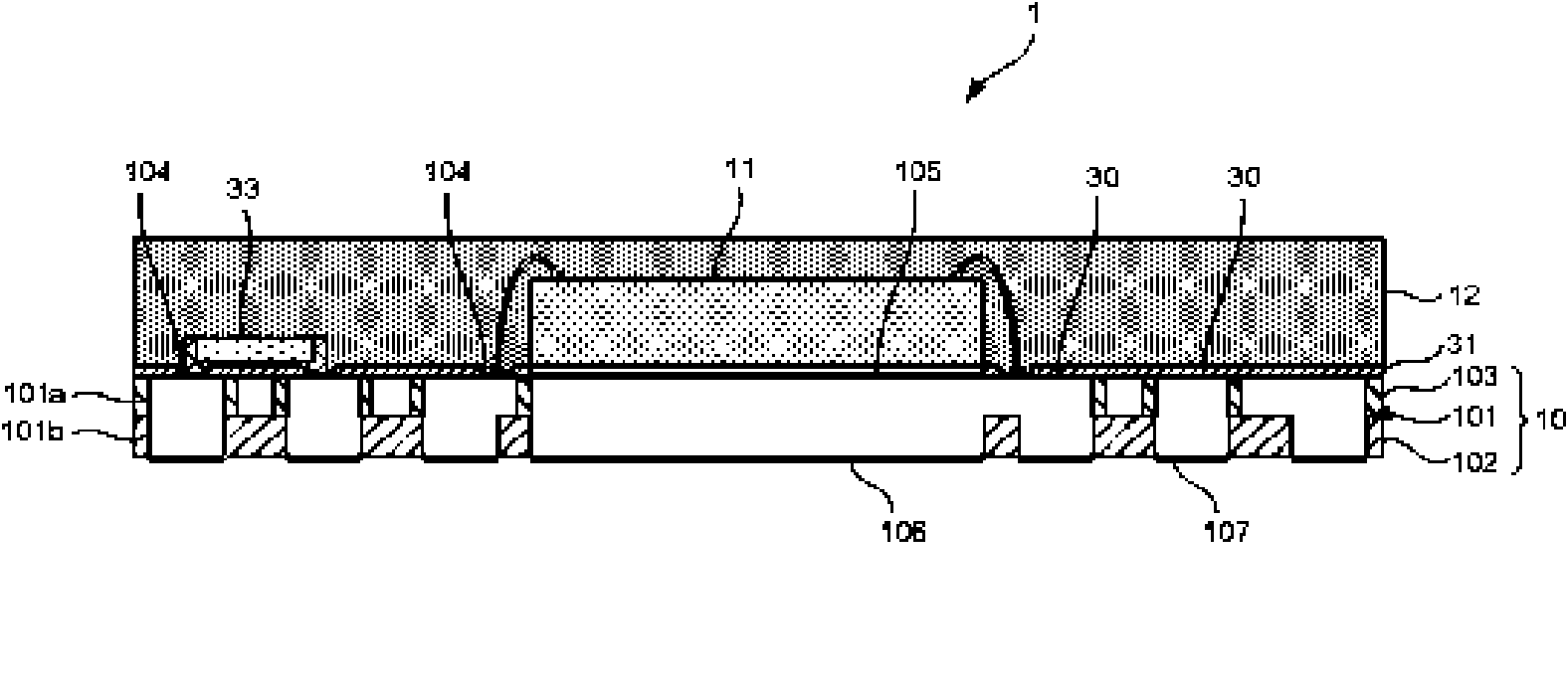

[0088] see figure 1 Shown is a schematic cross-sectional view of the semiconductor device according to the first preferred embodiment of the present invention. As shown in the figure: the present invention is a semiconductor device with heat dissipation gain, which at least includes a metal substrate 10 with a complete circuit surface and a complete pin surface, a semiconductor chip 11 and a molding material 12 .

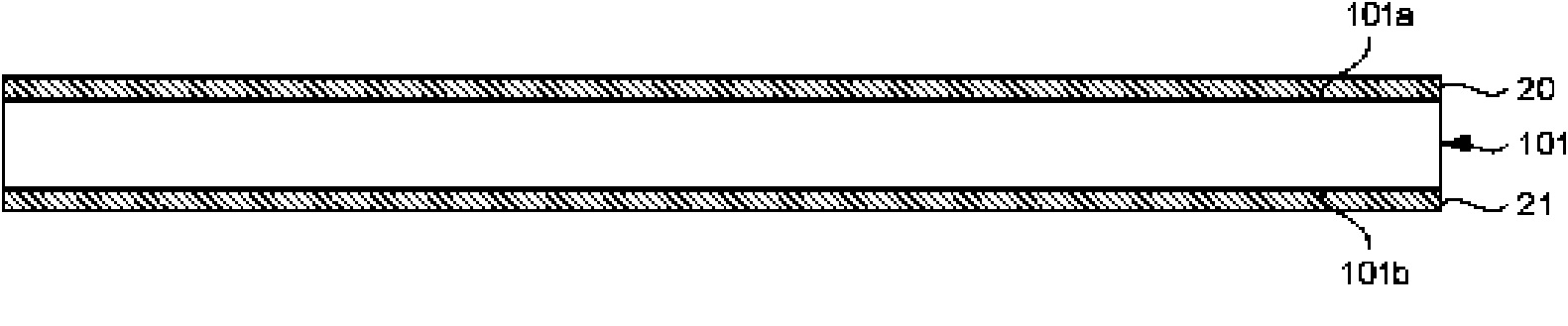

[0089] The metal substrate 10 includes a metal plate 101 , a first insulating layer 102 and a second insulating layer 103 . Wherein the metal plate 101 includes an upper portion 101a and a lower portion 101b relative to the upper portion, and the upper portion 101a of the metal plate 101 includes a crystal pad area and a plurality of patterned circuit areas, and the second insulating layer 103 is It is arranged between the patterned circuit areas and the crystal pad area; the lower part 101b of the metal plate 101 includes an electrical pad area connected to the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com