Soft measurement method of thickness of scale on surface of hot continuous rolling strip steel

A technology of surface oxidation and iron scale, applied in the field of steel rolling, can solve the problems of limited and unfavorable sampling points in the rolling line, reduce the thickness of oxide scale and improve the surface quality of strip steel, and achieve the effect of improving surface quality and reducing thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

[0041] The present embodiment adopts automobile frame steel 510L, and its composition is as shown in Table 1:

[0042] Table 1 chemical composition

[0043]

[0044] The soft measuring method for the thickness of iron oxide scale on the surface of hot continuous rolling strip comprises the following steps:

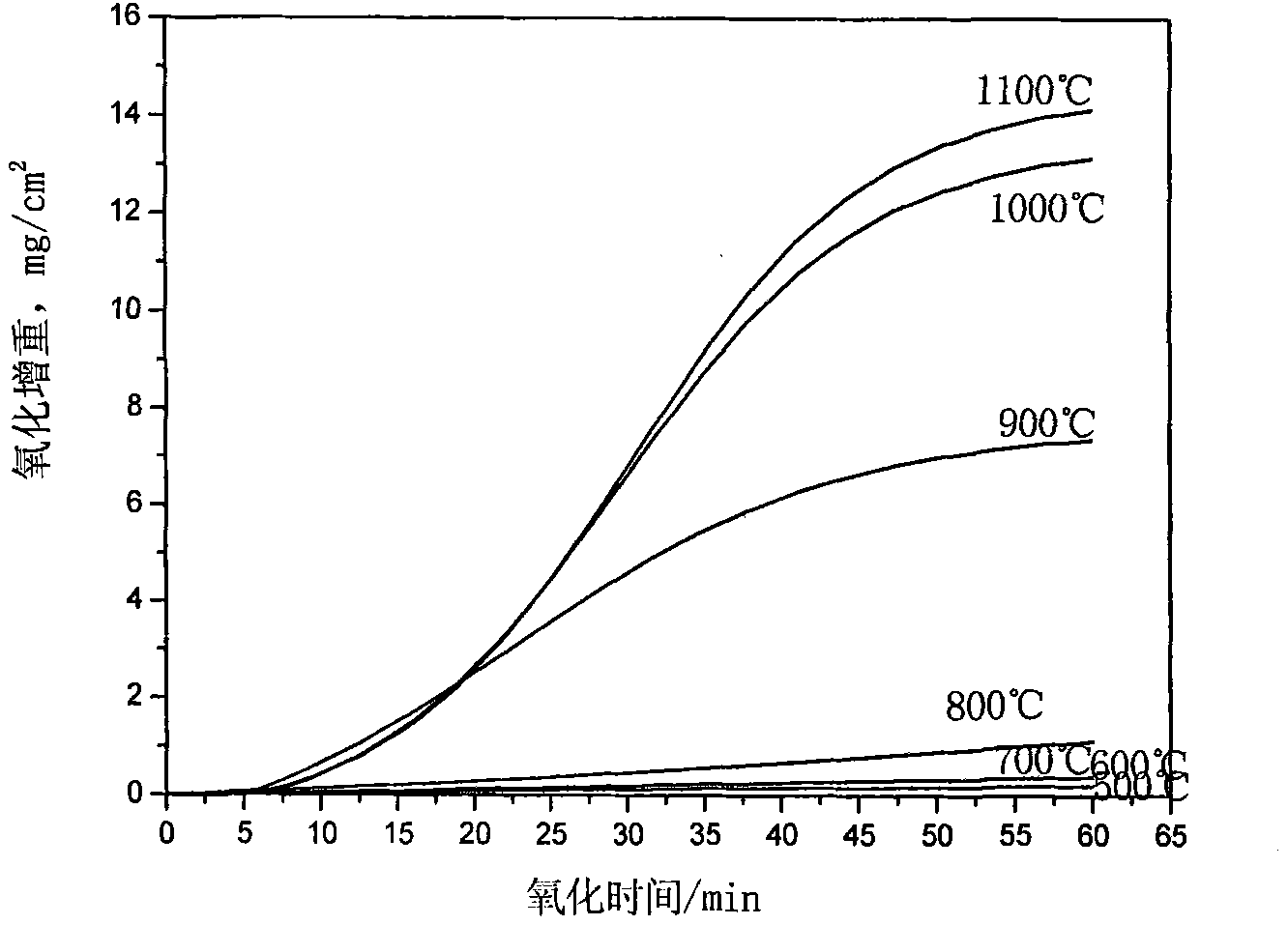

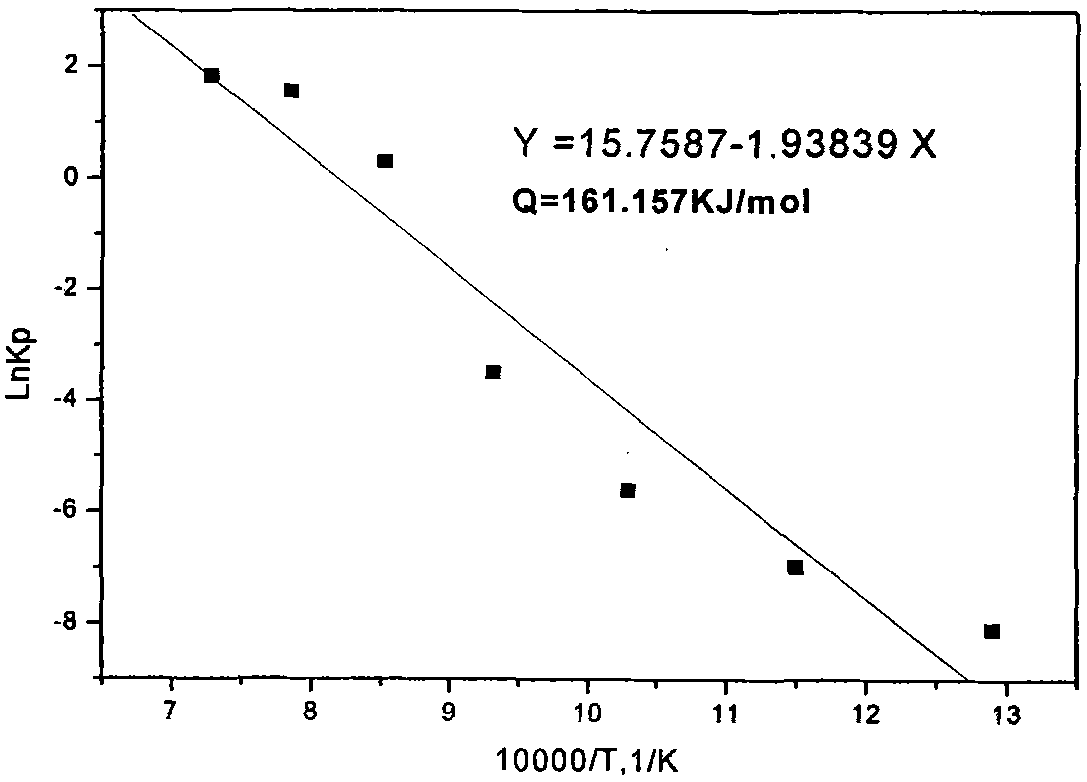

[0045] Step 1: Use a thermogravimetric analyzer to conduct an oxidation weight gain test: ultrasonically clean the wire-cut sample with acetone to wash off the emulsion on the surface of the sample, then polish it with sandpaper, clean it with alcohol, and dry it to prepare a size of For a sample of 10×15×(1.5~2)mm, a synchronous differential thermal analyzer is used to conduct an oxidation weight gain test. The synchronous thermal analyzer collects a mass weight gain signal every 0.3 seconds. The temperature is 500, 600, 700, 800, 90...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com